Differences between Forged Swage Nipples and Steel Reducers

Swage Nipples

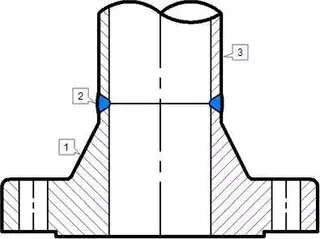

Swage Nipples also belong to reducer products, which are used for connecting two pipes with different diameters. The swage nipple has the same classification as the reducer and it can be classified into the eccentric swage nipple and the concentric swage nipple. The swage nipple generally adopts the MSS SP-95 or the BS3799 Standard.

The differences between the swage nipple and the reducer

1. Size ranges

The size range of the reducer is wide. The current size standard of the reducer is from DN15 to DN3400 (from 1/2 " to 136"), while the specification of the swage nipple is from DN6 to DN300 (from 1/4 " to 12").

2. Raw materials

Seamless steel pipes or steel plates are used as raw materials for reducers, while round bar steel or billet steel is selected as the raw material for swage nipples.

3. Manufacturing processes

The manufacturing process of the reducer is that we adopt the heat pressing process or the cold pressing process for the seamless reducer(the heat treatment is required for the cold pressing process) and we adopt the hot rolling process for the other reducer. The manufacturing process of the swage nipple is the forging process.

4. Connection ends

Beveled ends are basically adopted for reducers, and plain ends are hardly adopted for reducers. Although the plain end are allowed to be used for the stainless steel or the carbon steel reducer product whose wall thickness is lower than a certain amount. Swage nipples have more connection ends, and two ends of swage nipples can be the same or different based on the requirements of sites or designs; connection ends of swage nipples can be divided into beveled ends, plain ends and threaded ends three kinds. The following table is a good introduction to the connection end of the swage nipple.

Swage Nipples also belong to reducer products, which are used for connecting two pipes with different diameters. The swage nipple has the same classification as the reducer and it can be classified into the eccentric swage nipple and the concentric swage nipple. The swage nipple generally adopts the MSS SP-95 or the BS3799 Standard.

The differences between the swage nipple and the reducer

1. Size ranges

The size range of the reducer is wide. The current size standard of the reducer is from DN15 to DN3400 (from 1/2 " to 136"), while the specification of the swage nipple is from DN6 to DN300 (from 1/4 " to 12").

2. Raw materials

Seamless steel pipes or steel plates are used as raw materials for reducers, while round bar steel or billet steel is selected as the raw material for swage nipples.

3. Manufacturing processes

The manufacturing process of the reducer is that we adopt the heat pressing process or the cold pressing process for the seamless reducer(the heat treatment is required for the cold pressing process) and we adopt the hot rolling process for the other reducer. The manufacturing process of the swage nipple is the forging process.

4. Connection ends

Beveled ends are basically adopted for reducers, and plain ends are hardly adopted for reducers. Although the plain end are allowed to be used for the stainless steel or the carbon steel reducer product whose wall thickness is lower than a certain amount. Swage nipples have more connection ends, and two ends of swage nipples can be the same or different based on the requirements of sites or designs; connection ends of swage nipples can be divided into beveled ends, plain ends and threaded ends three kinds. The following table is a good introduction to the connection end of the swage nipple.

Different connection ends of swage nipples

| Specifications | |||

| 1. When we select the swage nipple, we should mark the end. We should also mark NPT or R for taper pipe threads. | |||

| 2. Big ends and small ends of swage nipples can be divided into plain ends, beveled ends and taper pipe threaded ends three kinds; the following is a table for nine combinations of big and small ends. | |||

| Type | Big End | Small End | Code |

| A | plain ends | plain ends | BEP |

| B | plain ends | beveled ends | LEP/SEB |

| C | threaded ends | LEP/SET | |

| D | beveled ends | plain ends | LEB/SEP |

| E | beveled ends | beveled ends | BEB |

| F | threaded ends | LEB/SET | |

| G | threaded ends | plain ends | LET/SEP |

| H | Thread | beveled ends | LET/SEB |

| I | threaded ends | BET | |

| 3. Wall thicknesses of swage nipples are generally Sch80 (3000LB) or Sch160 (6000LB). | |||

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Supplier Website

Source: https://www.landeepipefitting.com/differences-between-forged-swage-nipples-and-steel-reducers.html

.jpg)