Flange Connection Sealing: Principles, Issues & Solutions

In the industrial field, flange connections are an extremely common method of connection, widely used in industries such as petrochemicals, power generation, and water supply and drainage. They achieve sealing through the coordinated action of bolts, flanges, and gaskets, ensuring the safe operation of pipeline systems. However, flange leakage problems are frequently encountered, posing numerous hidden risks to industrial production. This article will deeply explore the sealing principles of flange connections, the causes of leakage, and preventive and solution measures, aiming to help maintenance personnel better address flange leakage issues and ensure the safety and efficiency of industrial environments.

Principles of Flange Connection Sealing

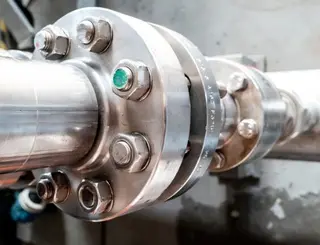

The sealing of a flange connection mainly relies on the coordinated action of bolts, flanges, and gaskets. The gasket is the core component for achieving sealing. The preload applied by the bolts generates sufficient pressure between the gasket and the flange sealing surface. This pressure causes the gasket surface to deform, filling the microscopic unevenness on the flange sealing surfaces, thus achieving sealing. In this process, specific pressure is a key concept, referring to the minimum unit compressive force applied to the gasket to achieve sealing.

When the pipeline reaches operating pressure, the axial force generated by internal pressure tends to separate the flanges, and the bolts also stretch accordingly, reducing the compressive force applied to the gasket. When the compressive force drops to a certain critical value, the remaining compressive force on the gasket is the effective tightening force. To ensure sealing performance, the effective tightening force of the gasket must be greater than the operating pressure of the pipeline. During the initial sealing stage, the plastic deformation of the gasket surface plays a decisive role, while under operational conditions, the elastic recovery within the gasket becomes the dominant factor.

Main Causes of Flange Leakage

As a widely used pipeline connection method, flange connections' sealing performance is crucial. However, flange leakage problems are frequently seen, bringing many hidden dangers to industrial production. The causes of flange leakage are diverse, involving installation, materials, environment, and other aspects. Understanding these causes helps better prevent and address flange leakage, ensuring the safe operation of industrial systems.

1. Improper Installation

Installation is the first line of defense for flange connection sealing, but improper installation is often the main culprit of leakage. When flange joints are not properly aligned or bolts are not tightened to the correct torque, sealing performance is greatly compromised.

For example, offset faces refer to the misalignment or non-concentricity of the pipeline and flange, causing flange faces not to be parallel. In this case, when the internal medium pressure exceeds the gasket's load pressure, flange leakage is inevitable. Misalignment refers to the pipeline and flange being perpendicular, but the two flanges are not concentric, making bolts unable to freely pass through bolt holes. Forcing the holes or using smaller bolts reduces flange tightening force, leading to leakage. Excessive gaps manifest as overly large flange spacing. Under external load, the gasket is impacted or vibrated, losing compressive force and ultimately causing sealing failure. Misdrilled holes can also cause stress on bolts, and long-term accumulation may lead to bolt breakage, resulting in sealing failure.

2. Corrosion

In industries that come into contact with corrosive materials, corrosion is another common cause of flange leakage. Corrosive media can erode gaskets over time, causing chemical changes. Over time, gaskets soften and lose compressive force, leading to flange leakage. Corrosion not only affects gaskets but can also damage the flange itself, reducing the overall strength and sealing performance of the flange joint.

3. Thermal Cycling

Thermal cycling also poses a serious threat to the sealing performance of flange connections. When flange joints are exposed to extreme temperature changes, gasket materials can degrade. For instance, in high-temperature environments, gasket materials may become brittle; in low-temperature conditions, gaskets may lose elasticity. Thermal expansion and contraction can also cause bolts to expand or contract, creating gaps in the gasket through which the medium leaks under pressure. Furthermore, repeated temperature changes can induce thermal stress in flanges and bolts, leading to flange warping or bolt loosening, further compromising sealing performance.

4. Improper Gasket Material Selection

Gasket material is a key factor affecting flange sealing performance. If the gasket material is incompatible with the fluid or gas transported through the flange joint, leakage may occur. For example, rubber gaskets are generally suitable for water or steam, but under high-temperature and high-pressure conditions, rubber gaskets may quickly age, deform, and lose sealing capability. Metal gaskets are more suitable for high-temperature, high-pressure applications, but in low-temperature or corrosive media environments, metal gaskets may fail due to material issues. Therefore, selecting gasket materials compatible with the specific application is crucial.

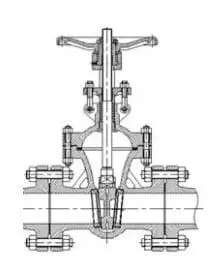

5. Flange and Bolt Effects

Flanges in actual operating conditions experience very complex forces. Bolts, gaskets, and internal pressure all exert forces on the flange. Although these forces may be acceptable in terms of strength, they can cause irregular flange deformation, leading to leakage. Flange design should not only meet strength requirements but also consider stiffness theory to minimize deformation during operation and meet non-leakage requirements. The bolt installation procedure is also extremely important. Correct bolt tightening sequences, such as cross-pattern symmetrical tightening, are critical for ensuring flange sealing and reducing tightening time. Improper bolt installation may lead to uneven flange stress and subsequent leakage.

Measures to Prevent Flange Leakage

Flange leakage can seriously affect industrial production and may cause safety accidents and environmental pollution. Therefore, effective preventive measures are essential. Through correct installation, material selection, regular maintenance, and reasonable design, the risk of flange leakage can be significantly reduced, ensuring safe and efficient operation of industrial systems.

1. Correct Flange Joint Installation

Ensuring correct installation of flange joints is the first step in preventing flange leakage. During installation, first ensure flange alignment so that the pipeline is perpendicular and concentric, and flange faces are parallel. Bolt tightening is crucial; a calibrated torque wrench must be used to tighten bolts to the correct torque. Correct torque ensures the gasket receives uniform pressure, achieving good sealing performance. Additionally, the installation sequence should adopt a cross-pattern symmetrical tightening method to avoid uneven flange stress and reduce leakage risk.

2. Selecting Appropriate Gasket Materials

Selecting appropriate gasket materials is vital for preventing flange leakage. When choosing gasket materials, the type of fluid or gas passing through the flange, temperature, and pressure conditions must be considered. For example, rubber gaskets are suitable for water or steam environments, while metal gaskets should be prioritized for high-temperature and high-pressure conditions. In addition to common rubber, cork, and metal gaskets, new sealing materials have emerged with technological development, such as graphite composite gaskets and PTFE gaskets, which exhibit excellent sealing performance under different working conditions. When selecting gasket materials, it is recommended to consult the gasket manufacturer or supplier to determine the most suitable material for a specific application.

3. Regular Inspection and Maintenance

Regular inspection and maintenance of flange joints is a key step in preventing leakage. Maintenance personnel should develop detailed inspection plans, checking for corrosion, gasket material degradation, and bolt loosening. If gasket aging, damage, or corrosion is found during inspection, replacement should be done promptly. If bolts are loose, retighten them to the correct torque. Additionally, attention should be paid to signs of thermal cycling, adopting insulation or heat protection measures to reduce temperature effects on flange joints and prevent gasket gaps caused by expansion and contraction.

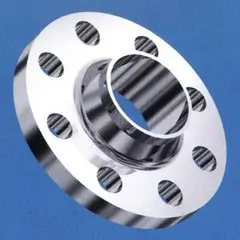

4. Reasonable Flange Structure Design

During flange design, the forces in actual operating conditions should be fully considered, and the design should follow stiffness theory to minimize deformation under working conditions. The shape and roughness of the flange sealing surface should match the gasket, as flatness and perpendicularity to the flange axis are prerequisites for uniform gasket compression. Design should also account for the impact of thermal expansion of pipelines causing thrust or eccentric forces, taking corresponding measures to avoid them, such as setting compensators or using flexible connections, to ensure the reliability of flange sealing.

Emergency Handling of Flange Leaks

Even with various preventive measures, flange leaks may still occur in certain cases. When a flange leak happens, maintenance personnel must act quickly to prevent further damage and hazards. First, identify the leak source, which may require visual inspection or leak detection equipment. Once the source is determined, appropriate repair measures should be taken immediately. If the leak is caused by gasket damage, replace it with a suitable gasket material. If caused by loose bolts, retighten them to the correct torque. In some complex cases, more comprehensive maintenance of the flange joint may be required, such as resurfacing flange sealing faces or replacing damaged bolts. Maintenance personnel should be equipped with the necessary tools and equipment to repair flange leaks quickly and effectively, ensuring the safe operation of industrial production.

Conclusion

Flange leakage is a problem that cannot be ignored in industrial environments. It not only may cause the escape of liquids or gases, harming the environment and workers, but also may trigger more serious safety incidents. By thoroughly understanding the sealing principles of flange connections, the causes of leakage, and implementing effective preventive and remedial measures, maintenance personnel can minimize the occurrence of flange leaks and ensure safe and efficient industrial production. In actual work, maintenance personnel should always prioritize the prevention and handling of flange leaks, strictly follow operational standards for installation, inspection, and maintenance, ensure the sealing performance of flange connections, and build a solid defense for the stable operation of industrial production.

Send your message to this supplier

Related Articles from the Supplier

Orifice Flange: A Reliable Tool for Flow Measurement

- Jan 06, 2025

Landee launched Stainless Steel Blind Flange

- Jun 27, 2012

Landee Released Lap joint Flange New Model

- Jan 22, 2013

Characteristics of Butterfly Valve Flange

- Jul 21, 2020

Related Articles from China Manufacturers

The Role of Gaskets in Flange Connection Sealing

- May 29, 2025

Flange connection and weld connection

- May 25, 2018

Head flange connection diagram

- May 31, 2017

Related Products Mentioned in the Article

Supplier Website

Source: https://www.landee.cn/news/industry-news/flange-connection-sealing-principles-issues-solutions.html