Complete Guide to Safety Valve Selection

Safety valves are indispensable safety protection devices in pressure vessels and pipeline systems. They can automatically open to relieve pressure when the system pressure exceeds the pre-set value, preventing explosions caused by overpressure. This article systematically introduces the classification methods, structural characteristics, selection essentials, and specific application scenarios of safety valves, helping engineering technicians and procurement personnel master the core knowledge of safety valves.

Classification by Overall Structure and Loading Mechanism

According to differences in overall structure and loading mechanism, safety valves are mainly divided into three types: weight-loaded lever type, spring-loaded type, and pilot-operated type. Each form has its own characteristics and is suitable for different operating conditions.

1. Weight-Loaded Lever Safety Valve

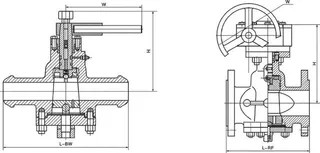

The working principle of the weight-loaded lever safety valve is to use a weight and a lever to balance the force acting on the valve disc. Based on the lever principle, a relatively small weight can be used to obtain a larger acting force through the amplification effect of the lever. By moving the position of the weight or changing its mass, the opening pressure of the safety valve can be adjusted.

The main advantages of this type of safety valve include: a simple structure, easy and relatively accurate adjustment; the applied load does not significantly increase as the valve disc rises; and suitability for higher-temperature applications. In the past, weight-loaded lever safety valves were widely used, especially on boilers and pressure vessels operating at higher temperatures.

However, this structure also has obvious disadvantages: the overall structure is relatively bulky; the loading mechanism is prone to vibration and often produces leakage due to vibration; the reseating pressure is relatively low, making it difficult to close and maintain tight sealing after opening. These limitations have gradually reduced its application range.

2. Spring-Loaded Safety Valve

Spring-loaded safety valves are currently the most widely used type. They utilize the force of a compressed spring to balance the force acting on the valve disc. The compression of the helical spring can be adjusted by turning the adjustment nut on top, thereby calibrating the opening pressure (set pressure) of the safety valve as required.

The advantages of spring-loaded safety valves are very prominent: lightweight and compact structure, high sensitivity; installation position is not restricted; low sensitivity to vibration, allowing use on mobile pressure vessels. These characteristics make them the preferred type in modern industry.

However, there are also some issues that require attention: as the valve disc rises, the spring compression increases, and the force acting on the disc also increases, which is unfavorable for the rapid opening of the safety valve; long-term exposure to high temperatures will reduce the elasticity of the spring; when used on high-temperature vessels, thermal insulation or heat dissipation for the spring must be considered, which makes the structure more complex.

3. Pilot-Operated Safety Valve

The pilot-operated safety valve consists of a main valve and an auxiliary valve, with the main valve actuated through the pulse action of the auxiliary valve. This structure is relatively complex and is generally only suitable for boilers and pressure vessels with very large required safety relief capacities. In special situations requiring extremely large relieving capacity, pilot-operated safety valves can demonstrate their unique advantages.

Classification by Medium Discharge Method

According to differences in medium discharge methods, safety valves can be divided into fully enclosed type, semi-enclosed type, and open type.

1. Fully Enclosed Safety Valve

When a fully enclosed safety valve exhausts, all gas is discharged through the discharge pipe, and the medium cannot leak outward. This type is mainly used for containers holding toxic or flammable gases, effectively preventing hazardous media from escaping and ensuring the safety of the operating environment and personnel.

2. Semi-Enclosed Safety Valve

Part of the gas discharged from a semi-enclosed safety valve passes through the discharge pipe, while another portion leaks from the gap between the valve cover and the valve stem. This type is mostly used for containers with gases that do not pollute the environment, simplifying the structure while ensuring basic safety.

3. Open Safety Valve

The bonnet of an open safety valve is exposed, allowing the spring chamber to communicate with the atmosphere, which helps reduce the temperature of the spring. This type is mainly suitable for containers with steam as the medium, as well as high-temperature gases that do not cause atmospheric pollution.

Classification by Valve Disc Opening Height

According to the ratio of the maximum opening height of the valve disc to the diameter of the safety valve flow passage, safety valves are mainly divided into low-lift type and full-lift type.

1. Low-Lift Safety Valve

The opening height of a low-lift safety valve is less than one-quarter of the flow passage diameter, typically between 1/40 and 1/20 of the flow passage diameter. Its action process is proportional, mainly used for liquid applications and sometimes for gas applications with very small discharge volumes.

2. Full-Lift Safety Valve

The opening height of a full-lift safety valve is greater than or equal to one-quarter of the flow passage diameter, and the discharge area is the minimum cross-sectional area of the valve seat throat. Its action process belongs to a two-stage action type and must rely on a lifting mechanism to achieve full opening. Full-lift safety valves are mainly used for gas media applications and can provide greater relieving capacity.

Classification by Operating Principle

According to the operating principle, safety valves can be divided into direct-acting type and indirect-acting type.

1. Direct-Acting Safety Valve

A direct-acting safety valve opens under the direct action of the working medium, relying on the pressure of the working medium to overcome the mechanical load applied to the valve disc by the loading mechanism. This type of safety valve has advantages such as simple structure, rapid action, and good reliability. However, because it relies on structural loading, the magnitude of the load is limited, and it cannot be used in high-pressure, large-diameter applications.

2. Indirect-Acting Safety Valve

Indirect-acting safety valves include pilot-operated safety valves and safety valves with power-assisted devices. This category of safety valves is suitable for high-pressure, large-diameter applications or situations requiring more precise control.

Methods for Determining Safety Valve Parameters

Correctly determining the various parameters of a safety valve is a key step in selection and mainly includes the following aspects:

1. Determination of Nominal Pressure

Select the nominal pressure according to the valve material, working temperature, and maximum working pressure. This is a fundamental parameter in safety valve selection and must be determined accurately.

2. Determination of Operating Pressure Rating

Select the operating pressure rating according to the design pressure and design temperature of the pressure vessel. It should be particularly noted that the operating pressure of a safety valve and the operating pressure rating of the spring have different meanings.

The operating pressure of a safety valve refers to the static pressure borne at the valve inlet during normal operation, which is the same as the operating pressure of the protected system or equipment. The operating pressure rating of the spring refers to the allowable working pressure range for a specific spring. Within this pressure range, the opening pressure (set pressure) of the safety valve can be adjusted by changing the spring preload compression.

Safety valves with the same nominal pressure can be divided into multiple operating pressure ratings according to spring design requirements. During selection, the operating pressure rating of the valve should be determined based on the required opening pressure value.

3. Determination of Relieving Pressure

The relieving pressure of a safety valve is generally 1.1 times the set pressure (opening pressure), while the relieving pressure of a steam boiler safety valve is 1.03 times the set pressure.

4. Determination of Discharge Capacity

Determine the discharge capacity according to the required relieving capacity. The discharge capacity of the safety valve must be greater than or equal to the required relieving capacity. The required relieving capacity of the protected system refers to the amount that must be discharged to prevent overpressure when the system experiences abnormal overpressure, and it is determined by factors such as the operating conditions, capacity, and possible causes of overpressure of the system or equipment.

5. Determination of Materials

When selecting the material of a safety valve, multiple factors should be considered, including the working temperature and pressure of the medium, the properties of the medium, as well as the manufacturability and economic efficiency of the material.

Selection of Safety Valves Under Special Operating Conditions

- High-temperature conditions: For safety valves used with steam whose opening pressure is greater than 3 MPa, or safety valves used with gases whose medium temperature exceeds 320°C, safety valves equipped with radiators (fins) should be selected to prevent the discharged medium from directly eroding the spring and to protect spring performance.

- Corrosive media: For safety valves used with corrosive media, bellows safety valves should be selected to prevent the spring and guiding mechanism from being corroded by the medium. The bellows can effectively isolate corrosive media from key components such as the spring.

- Back pressure variation: For safety valves subjected to additional back pressure where the variation exceeds 10% of the set pressure, bellows safety valves or balanced back pressure safety valves should be selected to ensure the stability of the opening pressure.

- Toxic and hazardous media: For flammable media or media with extreme or highly hazardous toxicity, enclosed safety valves must be adopted. If a lifting mechanism is required, a closed bonnet safety valve with a lever should be used to ensure that the medium does not leak.

- Mobile equipment: Mobile equipment should use spring-loaded safety valves because their structure is lightweight, they are not sensitive to vibration, and they are suitable for mobile operating conditions.

Selection Recommendations for Different Application Scenarios

- Liquefied tank trucks: Liquefied tank trucks should adopt built-in safety valves, as this structure can better adapt to vibration and impact during transportation.

- Conditions requiring large discharge capacity: For conditions requiring large discharge capacity, full-lift safety valves should be selected to provide sufficient discharge area.

- Conditions with stable operating pressure and small discharge volume: For conditions with stable operating pressure and small discharge volume, low-lift safety valves should be selected. This type responds sensitively and is suitable for small-flow relief.

- High-pressure, large-discharge conditions: For high-pressure conditions with large discharge volumes, indirect-starting types such as pilot-operated safety valves should be selected to meet large-diameter and high-pressure requirements.

- Requirements for long vessels: For containers exceeding 6 meters in length, two or more safety valves should be installed to ensure effective relief at any position.

- Low-pressure fixed vessels: Fixed vessels with low working pressure may use deadweight types (such as pressure cookers) or lever weight safety valves, which have simple structures and relatively low costs.

- Media prone to clogging: For media that are relatively viscous and prone to blockage, a series combination relief device consisting of a safety valve and a rupture disc should be selected. The rupture disc can prevent blockage of the safety valve seat.

Selection Guide by Medium Type and State

- Gas or steam discharge: When discharging gas or steam, select full-lift safety valves to obtain maximum relieving capacity.

- Liquid discharge: When discharging liquids, either full-lift or low-lift safety valves may be selected depending on the discharge volume.

- Steam or air discharge: When discharging steam or air, safety valves with a lever may be selected to facilitate manual inspection and operation.

- High-temperature, high-pressure gas: For safety valves used with gases whose set pressure exceeds 3 MPa and temperature exceeds 235°C, select safety valves equipped with cooling fins.

- Media permitted to discharge into the atmosphere: For media allowed to be discharged into the atmosphere, select safety valves with open bonnets, which help reduce spring temperature.

- Media not permitted to discharge into the atmosphere: For media that must not be discharged into the atmosphere, select safety valves with closed bonnets to prevent leakage.

- Highly toxic or strongly corrosive media: For discharging highly toxic, strongly corrosive, or extremely hazardous media, select bellows safety valves to ensure sealing reliability.

- High back-pressure conditions: In high back-pressure conditions, select balanced safety valves or pilot-controlled safety valves to ensure accurate opening pressure.

Conclusion

The selection of safety valves is a technical task that requires comprehensive consideration of multiple factors. From structural form to discharge method, and from opening height to operating principle, each classification dimension corresponds to specific application scenarios. Correct selection must not only meet basic relieving requirements but also consider medium characteristics, operating temperature, pressure ratings, environmental factors, and economic efficiency.

With the continuous development of industrial technology, the design and manufacturing of safety valves are also constantly advancing. Engineering technicians should fully understand the characteristics and applicable ranges of various safety valves and carry out scientific selection in combination with actual operating conditions to ensure the safe operation of pressure vessels and pipeline systems. At the same time, regular maintenance and calibration are important links in ensuring the reliable operation of safety valves and must not be overlooked.

Send your message to this supplier

Related Articles from the Supplier

Complete Guide to Safety Valve Selection

- Feb 12, 2026

A Complete Guide to Diaphragm Valve Maintenance

- Jan 06, 2026

A Complete Guide to Mechanical Steam Traps

- Jan 08, 2026

How to Properly Install Steam Traps: Complete Guide

- Dec 24, 2025

Complete Installation Guide for Y-Type Strainers

- Nov 06, 2025

Related Articles from China Manufacturers

Complete Guide to Lubricated Plug Valves

- Jul 31, 2024

Complete Guide to Cryogenic Ball Valve Maintenance

- Aug 14, 2024

Complete Guide to Infrared Sensors

- Aug 21, 2024

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/complete-guide-to-safety-valve-selection.html