Common Problems in Pneumatic Control Valve Operation

In process industries such as petrochemical, electric power, and metallurgy, pneumatic control valves receive signals from the control system to precisely regulate process parameters such as the flow, pressure, and temperature of the medium in pipelines. Using compressed air as the power source and a cylinder as the actuator, and working in conjunction with accessories such as valve positioners and converters, they achieve switching or proportional regulation and are an indispensable part of control systems. Because penumatic control valves operate for long periods under harsh conditions such as high temperature, high pressure, and corrosive media, combined with frequent switching actions, faults are unavoidable. For instrumentation maintenance personnel, mastering the diagnosis and handling methods of common faults enables timely troubleshooting and ensures the safe and stable operation of production systems.

Troubleshooting When the Control Valve Does Not Move at All

When a control valve fails to move, systematic troubleshooting should be carried out from simple to complex factors.

1. Air Supply Inspection

First, check whether the air supply (instrument air) is unobstructed and whether the air supply pressure meets the operating requirements of the valve. Common air supply faults include: the onsite air supply is not turned on; excessive moisture in the air supply freezes in cold weather; the purified air supply stops; leakage in the main air pipeline or blockage in air lines leads to excessively low air pressure, etc. These problems can prevent the control valve from fully opening or closing, or even cause it not to move at all.

2. Signal Inspection

If the air supply is confirmed to be normal, the next step is to check whether there is output signal air pressure. For electrically controlled intelligent control valves, use a digital multimeter to measure whether the DC4–20 mA control power signal transmitted from the central control room is normal. If the signal is abnormal or completely absent, check whether there are faults in the PLC system, signal lines, etc. If the signal is normal but the valve still does not move, the valve positioner needs to be replaced.

For control valves that use mechanical controllers or positioners, replace the mechanical pressure controller or positioner. At the same time, check whether the valves on the signal acquisition pipeline of the medium on the control valve installation pipeline are fully open and whether there is severe leakage. Any abnormality found should be handled promptly.

3. Actuator Fault Inspection

When the output signal air pressure is normal but the valve still does not move, it is necessary to further inspect the actuator. First, check whether the diaphragm of the pneumatic diaphragm actuator has severe air leakage. If leakage exists, replace the diaphragm and related sealing components in time.

If the diaphragm is intact with no leakage, the main valve plug and sleeve or valve seat may be stuck, requiring disassembly to inspect the main valve and remove debris. In addition, severe bending or deformation of the valve stem can also cause the valve not to move, requiring disassembly and replacement according to the situation.

4. Other Mechanical Faults

Leakage in signal air pipelines, amplifier failure, or improper adjustment are also common causes. If the main air supply does not enter the diaphragm chamber through the amplifier, adjust or replace the amplifier promptly. For signal air pipelines, carefully check for minor leakage with soapy water, and once a leak point is found, address it immediately.

Unstable Operation and Oscillation of the Control Valve

When a control valve produces regulating oscillation and unstable control during operation, it will seriously affect process control accuracy, and corresponding measures should be taken for different causes.

1. Air Supply Pressure Fluctuation

Large variations in air supply pressure or abnormal operation of filters and pressure-reducing valves are common causes. The operating condition of the compressed air system should be checked, and filters or pressure-reducing valves should be replaced in time. After long-term use, excessive dirt accumulation in the air filter regulator can cause air leakage when the black knob of the pressure-reducing valve is opened, making the output air pressure lower than the specified pressure; in this case, the air filter regulator needs to be cleaned or replaced.

Air leakage in field air lines and loose joints can also lead to insufficient air pressure, preventing the control valve from fully opening or closing or even causing it not to move. Faults in the filter pressure-reducing valve that result in unstable air pressure can likewise cause oscillation in the control valve.

2. Electrical Control System Issues

Loose, detached, short-circuited, or open wiring terminals in power lines, as well as excessive dust accumulation on circuit boards leading to poor contact, can all cause signal fluctuations and result in vibration of the control valve. After heavy rain or typhoons, water ingress and moisture in equipment can cause wiring short circuits, preventing the control valve from fully opening or closing. Reversed polarity will cause the control valve not to move.

Faults in the middle section of power lines should not be ignored. Failure of insulation tape may cause the insulation sheath of wires to fall off, resulting in short circuits between wires; alternatively, onsite vibration may cause wire breakage. Both situations can lead to discontinuous valve action, oscillation, inability to fully open or close, or even complete inaction. Wiring errors after control valve maintenance are also common causes of faults.

3. Positioner and Feedback System Faults

Unstable output signals from the control valve will cause operational fluctuations. Loose or detached fixing nuts on the feedback rod, or springs falling off the feedback rod, will cause the feedback rod to become loose, detached, or stuck, resulting in oscillation of the control valve. A faulty position sensor in the positioner may display overtravel in the central control room when vibration reaches the defective point and return to normal after a while; this can be resolved by replacement.

Improper tuning of the PID parameters in the positioner is also an important cause of oscillation. For electrically controlled intelligent positioners, initialization calibration should first be performed. If instability persists after calibration, the intelligent positioner should be replaced. If instability still remains after replacement, the PID parameters should be tuned. For mechanical controllers or positioners, replace them and perform adjustment; if instability persists, inspect and replace the signal air amplifier and adjust it accordingly.

4. Mechanical Connection Problems

Carefully check whether there is any gap at the connection between the positioner and the main valve. Replace or tighten the relevant connecting components between the positioner and the main valve. If the pipeline is not concentric with the valve body during installation, excessive additional stress will be applied to the control valve, causing oscillation and preventing it from fully opening or closing.

Causes and Handling of Sluggish Control Valve Action

Sluggish action of the control valve affects the response speed of the control system and needs to be handled promptly.

- Internal Valve Body Problems: Sticky substances blocking the interior of the valve body are a common cause, requiring disassembly of the main valve body to clean the sticky materials. Debris blocking the valve plug can also cause sluggish action and requires disassembly, inspection, and cleaning.

- Packing Problems: Deteriorated and hardened valve stem packing, or dried lubricant in graphite or asbestos packing, will increase friction resistance. The main valve body needs to be disassembled and the valve stem packing replaced. If the packing is tightened excessively, friction resistance increases; loosen the packing gland nut, reciprocate the main valve several times, and then adjust the gland nut to the appropriate torque.

- Valve Stem Problems: An unstraight valve stem will cause high friction resistance and requires disassembly of the main valve followed by stem replacement. Loose fixing nuts between the valve stem and connecting components can cause the valve stem and plug to become non-concentric, which not only prevents tight valve closure but also increases stress, leading to high-frequency vibration or even fracture of the valve stem.

- Minor Air Circuit Leakage: Minor leakage in the diaphragm of the pneumatic diaphragm actuator or in signal air pipelines, although not causing complete inaction, will result in sluggish movement. Replace the diaphragm of the pneumatic diaphragm actuator and address leakage in the signal air pipelines.

Normal Valve Action but Abnormal Process Control Parameters

Sometimes the control valve itself appears to operate normally, but the process control parameters are abnormal. Such faults are concealed and require careful troubleshooting.

1. Valve Plug Detachment

Detachment of the control valve plug is one of the most serious situations. Although the actuator is operating, the plug has lost its control function. Disassemble and inspect the main valve body of the control valve and restore the plug according to inspection results.

2. Valve Plug Displacement

Relative displacement occurs at the connection between the valve plug and the valve stem without complete separation, causing the valve opening to mismatch the actuator stroke. Disassemble for inspection and restore the plug position.

3. Valve Stem Fracture

After the valve stem fractures, actuator motion cannot be transmitted to the valve plug. Disassemble for inspection and replace the valve stem.

4. Sealing Problems

Wear of the valve plug or valve seat (caused by erosion from the medium, scratches from rust, welding slag, and other debris), sticking (due to various impurities in the medium), and poor sealing (caused by worn sealing rings) will result in excessive medium flow even when the valve is fully closed, making control impossible.

5. Packing Gland Problems

Packing that is too tight or too loose will both create problems. Excessive tightness causes sluggish or jumping movement of the valve stem; excessive looseness leads to medium leakage. If the medium is heavy oil, combustion is very likely, potentially causing major accidents.

6. System Parameter Problems

Other control parameters in the controlled medium system may be inappropriate and need to be adjusted within the design requirements.

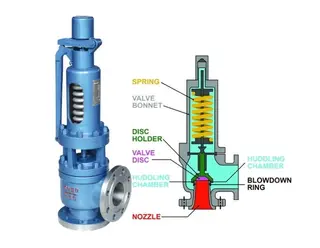

Actuator Diaphragm Head Faults

The diaphragm head is a key component of pneumatic control valves. Common faults include:

After long-term use, the diaphragm ages and deteriorates, elasticity decreases, sealing performance worsens, and diaphragm air leakage occurs. Aging compression springs with reduced elasticity or fracture will prevent the control valve from fully opening or closing or even cause loss of control. These problems should be addressed promptly by replacing the diaphragm and springs.

Routine Maintenance Recommendations

To ensure long-term stable and reliable operation of pneumatic control valves, the following maintenance work is recommended:

Regularly check air supply quality to ensure compressed air is dry and clean, and periodically drain accumulated water and contaminants from filters. Regularly inspect the tightening condition of all connection points to prevent loosening. Regularly check packing sealing conditions and adjust or replace them promptly. Periodically calibrate the positioner to ensure control accuracy. Establish maintenance records documenting each inspection and repair for easier fault analysis.

Conclusion

Fault diagnosis of pneumatic control valves requires a systematic approach, troubleshooting step by step from air supply, power supply, signals, and mechanical components. For instrumentation maintenance personnel, familiarity with the structural principles of control valves and mastery of the phenomena and causes of common faults enable quick and accurate identification of fault points and the adoption of effective measures, which is key to ensuring the normal operation of industrial automatic control systems. Through scientific maintenance and timely fault handling, the service life of control valves can be extended, and the reliability and stability of control systems can be improved.

Send your message to this supplier

Related Articles from the Supplier

Common Problems in Pneumatic Control Valve Operation

- Feb 14, 2026

Common Materials for Valve Trims

- Dec 14, 2024

Common Failures and Solutions of Gate Valves

- Nov 03, 2025

Related Articles from China Manufacturers

Common Problems in the Use of Valves

- Jun 13, 2023

Common problems in flange use

- Jun 19, 2020

10 Common Problems Encountered in Valve Applications

- Mar 20, 2024

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/common-problems-in-pneumatic-control-valve-operation.html