Ball Valve Leakage: Causes, Prevention and Solutions

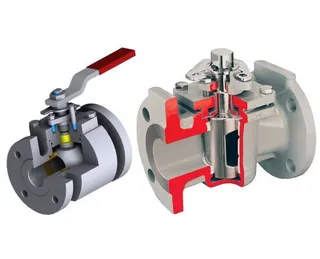

Ball valves are among the most widely used valve types in industrial pipeline systems. Thanks to their simple structure, reliable sealing performance, and convenient operation, they are extensively applied in industries such as petroleum, chemical processing, power generation, metallurgy, and municipal water supply. However, leakage problems can still occur during actual operation. Such issues not only reduce production efficiency but may also cause environmental pollution and safety hazards. This article provides a comprehensive analysis of various ball valve leakage causes and offers systematic solutions to help engineering and technical personnel better prevent and address leakage failures.

Internal Leakage in Ball Valves

Internal leakage refers to the phenomenon in which the medium continues to pass through the valve even when it is fully closed. Because the leakage occurs inside the valve, it is usually not directly visible but can be detected through pressure drops or medium loss within the system. Internal leakage is one of the most common ball valve failures and can severely compromise the valve's shutoff capability.

1. Internal Leakage Caused Before Installation

- Improper transportation and lifting: Incorrect handling during transportation or lifting may damage the overall valve structure. Precision internal components such as the ball and seat are highly sensitive to shock and vibration. Even if no visible external damage is present, sealing performance may deteriorate. Violent impacts should be avoided during transport, and dedicated lifting tools must be used. Never lift the valve via the stem or actuator.

- Factory quality issues: Some valves are not adequately dried or protected against corrosion after hydrostatic testing. Residual moisture can corrode sealing surfaces, especially during long-term storage or transport, ultimately leading to poor sealing. Users should inspect protective conditions upon receipt and perform additional drying or anti-corrosion treatment if necessary.

- Insufficient site protection: Construction environments are often complex. If blind flanges are not installed at both ends of the valve, rainwater, sand, and dust can enter the seat area. These contaminants may scratch sealing surfaces during installation or embed into them during operation, causing permanent damage. Valves should remain sealed at both ends and be stored in a clean, dry environment before installation.

2. Internal Leakage Caused During Installation

- Insufficient lubrication: Failing to inject grease into the valve seat during installation is a common mistake. Grease forms a protective film that prevents contaminants from entering the rear cavity of the seat. Without it, debris can cause wear during operation. Additionally, welding spatter and high temperatures may directly damage sealing surfaces if grease protection is absent.

- Improper installation position: Ball valves must be installed in the fully open position during welding. If welding is performed while the valve is partially open, spatter can adhere to the ball surface. When the ball rotates, the hardened particles act as abrasives, scratching the seat and causing severe internal leakage.

- Damage from construction residues: Welding slag, metal chips, and other debris generated during pipeline construction can scratch precision sealing surfaces if not thoroughly removed beforehand. Under high pressure, these micro-scratches can expand and ultimately lead to seal failure. Proper pipeline flushing and cleaning are essential.

- Assembly misalignment: If the stem drive sleeve or other accessories are not properly aligned, additional stress may develop, resulting in leakage. Such problems often stem from insufficient manufacturing precision or forced alignment during installation. All components should be naturally centered to avoid stress.

3. Internal Leakage Caused by Improper Operation and Maintenance

- Lack of scientific maintenance: Some operators neglect regular maintenance due to perceived costs or lack of proper valve management methods. Minor issues accumulate over time, eventually leading to premature failure. Preventive maintenance is far less expensive than post-failure repairs or replacements.

- Improper operation: Operating valves too quickly can create water hammer, damaging sealing surfaces. Using improper tools may harm the stem or actuator, while forcing operation under pressure accelerates wear.

- Pipeline pigging damage: Although pigging is necessary for maintaining pipeline flow, improper operation may cause the pig to strike sealing surfaces. Confirm that the valve is fully open before pigging.

- Long-term inactivity: Valves left unused for extended periods may experience adhesion or locking between the seat and ball. Restarting operation then requires higher torque, potentially tearing or wearing the sealing surface. Even rarely used valves should be periodically cycled.

- Incomplete opening or closing: A deviation of just 2°–3° from the correct ball position can cause leakage. Large-diameter valves often have stem stops that accumulate corrosion, dust, or paint over time, preventing full rotation—especially in buried installations.

- Actuator problems: Poorly maintained limit devices may suffer from hardened grease or loose bolts, resulting in inaccurate positioning. Electric actuators set without considering actual seating conditions may also fail to close tightly. Regular inspection is essential.

- Sealant failure: Without routine maintenance, sealing grease can dry and harden, obstructing seat movement and causing sealing failure. Sealant provides lubrication and protection and must be replenished periodically.

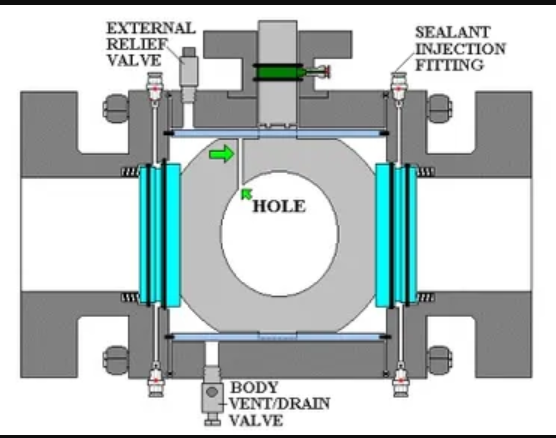

4. Methods for Addressing Internal Leakage

- Preliminary inspection and adjustment: First, check limit settings. Many internal leaks result from incomplete closure and can be resolved through adjustment.

- Grease injection: Inject grease into the seat and observe whether leakage stops. A steadily rising pressure gauge suggests intact sealing surfaces; inability to build pressure indicates a serious leakage path.

- Cleaning treatment: If grease injection fails, hardened sealant or damaged surfaces may be the cause. Inject valve cleaning fluid and soak the sealing surfaces—typically at least 30 minutes, or longer for severe cases. Cycling the valve during soaking improves penetration.

- Contaminant removal: After cleaning, reinject grease and intermittently operate the valve to flush impurities from the seat cavity and sealing surfaces.

- Enhanced sealing: If leakage persists, inject reinforced sealant while venting the valve cavity. Pressure differentials help the sealant fill micro-gaps.

- Final solution: If the problem remains unresolved, the sealing surfaces are likely severely damaged, requiring professional repair or valve replacement.

Leakage at the Valve Body and Bonnet

Unlike internal leakage, body and bonnet leakage is clearly visible as the medium escapes directly through the valve shell. In cold regions, frozen valve bodies may rupture under pressure, creating significant hazards.

1. Major Causes

Casting defects: Sand holes, porosity, and slag inclusions may form leakage channels under pressure.

Freeze cracking: Water trapped inside the valve expands upon freezing, causing radial cracks through the wall thickness.

Welding defects: Slag inclusion, incomplete penetration, or stress cracks may propagate during operation.

Mechanical damage: Cast iron valves are brittle and susceptible to impact from falling tools or materials.

2. Prevention and Treatment

Select qualified manufacturers and perform strength and sealing tests before installation.

Apply insulation or heat tracing in sub-zero environments and drain unused valves.

Follow welding procedures strictly and conduct nondestructive testing afterward.

Prevent mechanical damage by avoiding heavy loads, using dedicated supports, and lifting with slings.

Leakage at the Packing

The stem packing connects the valve's internal and external environments. It must allow smooth stem movement while preventing medium escape, making it inherently prone to leakage.

1. Main Causes

Incorrect packing material selection

Improper installation

Aging and hardening

Stem defects such as bending or corrosion

Insufficient compression or damaged gland components

2. Prevention and Treatment

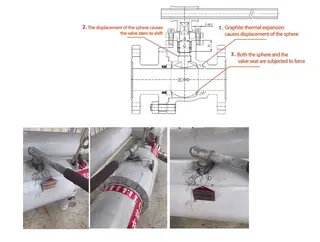

Select packing compatible with media, temperature, and pressure. Common materials include graphite, PTFE, and aramid fiber.

Install packing ring by ring with staggered joints.

Replace aged packing promptly and clean the stuffing box thoroughly.

Maintain the stem, straighten bends, and prevent corrosion.

Ensure proper preload—too tight increases torque; too loose compromises sealing.

Repair damaged glands and bolts and operate valves according to procedures.

Sealing Surface Leakage

Sealing surface performance directly determines the valve's shutoff capability.

1. Major Causes

Uneven lapping creates microscopic gaps.

Poor alignment between stem and closing member leads to uneven contact.

Bent stems or improper assembly cause localized sealing.

Incorrect material selection results in premature failure.

2. Prevention and Treatment

Choose appropriate sealing materials—hard seals for high temperature/pressure or particle-laden media; soft seals for clean, low-pressure service.

Operate smoothly and inspect sealing conditions regularly.

Tighten flange bolts evenly, preferably with a torque wrench.

Install gaskets centrally without overlap or double layering.

Repair corroded or damaged surfaces through grinding and inspection; rebuild or replace severely damaged areas.

Maintain cleanliness during gasket installation.

Leakage at Seal Ring Connections

Seal ring attachment points are also potential leakage sources, often concealed and difficult to address.

1. Main Causes

Insufficient rolling or fixation

Poor welding quality with defects such as porosity

Loose threaded or bolted connections

Corrosion damage on connection surfaces

2. Prevention and Treatment

Inject adhesive into leaking rolled joints and re-roll to fill micro-gaps.

Reweld according to specifications when welding defects are present.

Clean and replace damaged screws or retaining rings and reassemble after lapping.

Repair corroded surfaces by grinding or bonding; replace seal rings if necessary.

Comprehensive Strategies for Preventing Ball Valve Leakage

Design and selection stage: Choose valve types and materials based on actual operating conditions, including media characteristics, temperature, pressure, and flow rate. Use reliable brands for critical applications.

Procurement and acceptance: Verify supplier qualifications and require complete quality documentation. Conduct visual inspections, dimensional checks, and performance tests upon delivery.

Installation stage: Develop detailed installation procedures and train personnel. Pay special attention to cleanliness, welding processes, and pressure testing.

Operation and maintenance stage: Establish a valve registry documenting specifications, locations, commissioning dates, and maintenance history. Implement regular inspection, cleaning, lubrication, and adjustment plans, and monitor critical valves.

Failure handling stage: Classify leakage severity and follow structured response procedures. Minor leaks may be resolved through adjustment or grease injection, while severe cases require repair plans or replacement. Analyze root causes afterward to improve preventive measures.

Conclusion

Ball valve leakage involves multiple stages, including design, manufacturing, installation, operation, and maintenance. Negligence at any stage can lead to failure. As this systematic analysis demonstrates, most leakage issues are preventable and manageable. The key lies in establishing a scientific management system, strictly following technical standards, and emphasizing routine maintenance. Only through these practices can long-term stable valve operation be ensured, safeguarding both the safety and economic efficiency of industrial production. Engineering professionals should continuously enhance their knowledge and practical experience to better identify and resolve ball valve leakage issues, thereby supporting reliable industrial operations.

Send your message to this supplier

Related Articles from the Supplier

Ball Valve Leakage: Causes, Prevention and Solutions

- Feb 13, 2026

How to Address Ball Valve Seat Damage?

- Nov 28, 2025

Pneumatic Ball Valve Selection Guide

- Sep 15, 2025

An Introduction to Orbit Ball Valve

- Nov 26, 2025

Related Articles from China Manufacturers

Ball Valve Internal Leakage: Causes and Solutions

- Jan 12, 2024

Causes and Solutions of Ball Valve Internal Leakage

- Mar 27, 2019

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/ball-valve-leakage-causes-prevention-and-solutions.html