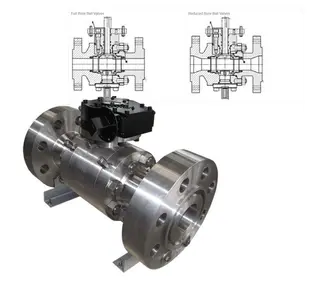

ASTM A182 F51 Trunnion Ball Valves, API 6D, 12 Inch, 1500 LB

Product Name: Forged Steel Trunnion Mounted Ball Valve

Type: Trunnion Mounted Ball Valve

Design Standard: API 6D

Body Material: ASTM A182 F51

Size: 12 Inch, DN300

Pressure: Class 1500 LB, PN250

End Connection: RTJ Flanged

Operation: Gear Box

Medium: Water, Oil, Gas, etc

Temperature Range: -46°C to 120°C

Trunnion Mounted Ball Valves offer easy and smooth operation even at high line pressures. The valves are equipped with carefully aligned bearings that facilitate low-torque operation. The ball is securely positioned yet free to rotate. All Cast Trunnion Ball Valves are made with reliable, high-quality castings and feature a fire-safe design certified in accordance with BS 6755, API 607, and API 6FA. They meet all applicable ASME standards. Cast Steel Trunnion Ball Valves are available in two types: Two-Piece Split Body and Three-Piece Bolted Body. These valves are designed and manufactured to the most up-to-date international standards, including API 6D, ASME B16.34, BS 5351, or their equivalents. They come with standard features such as Fire Safe, Anti-Static, and Stem Blow-out Proof.

Technical Specification

» Size Range: NPS 2-48 Inch (DN50-DN1200)

» Design Pressure: Class 150-2500 LB (PN10-PN420)

» Body Materials: Cast Carbon Steel, Stainless Steel, Duplex, and Special Alloys

» Trim Materials: 13%Cr, SS 304, SS 304L, SS 316, SS 316L, and other options

» Seat Materials: RPTFE, DEVLON, PEEK

» End Connections: Flanged RF/RTJ, Butt Welded

» Operation Types: Handle, Worm Gear, Electric, Pneumatic

» Design & Manufacturing Standards: API 6D, BS 5351, ASME B16.34

» Face-to-Face Dimensions: ASME B16.10

» Flanged Connections: ASME B16.5, ASME B16.47

» Welded Ends: ASME B16.25

» Testing & Inspection: API 598, API 6D

» Fire Safety Compliance: API 607, API 6FA

Product Features

» Double Block and Bleed (DBB): Achieves bidirectional flow blocking and pressure relief between seats.

» Low Operating Torque: Ensures smooth and effortless valve operation.

» Emergency Sealing Device: Provides an extra layer of sealing for emergencies.

» Fireproof Structure Design: Meets fire safety standards to maintain functionality in fire scenarios.

» Anti-static Structure: Prevents static buildup to reduce ignition risks in hazardous areas.

» Reliable Seat Sealing Structure: Ensures a tight seal to prevent leaks.

» Single Sealing (Automatic Pressure Relief in Middle Cavity of Valve): Features a single seal with automatic pressure relief in the valve's middle cavity.

» Double Sealing (Double Piston): Offers enhanced sealing with a double piston mechanism.

» Safety Relief Device: Releases excess pressure to ensure safe operation.

» Special Structure of Automatic Pressure Relief Towards Upstream: Automatically relieves pressure towards the upstream side.

» Blow-out Proof Stem: Prevents stem blow-out during operation.

» Corrosion Resistance and Sulfide Stress Resistance: Provides durability in corrosive environments and resistance to sulfide stress cracking.

» Optional Locking Device or Stem Extension: Available with optional locking devices or stem extensions.

» Optional Direct Mounting to ISO 5211: Compatible with ISO 5211 actuation standards for direct mounting.

» Full Port or Reduced Bore: Available in full port and reduced bore options to meet different flow requirements.

Send your message to this supplier

Related Articles from the Supplier

Full Bore Ball Valves vs. Reduced Bore Ball Valves

- Oct 27, 2025

Classification Of Ball Valves

- May 03, 2018

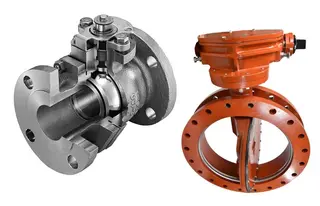

Ball Valves and Butterfly Valves: How to Choose?

- Sep 02, 2025

Metal to Metal Ball Valves Characteristics

- Dec 14, 2024

What are Eccentric Segmented Ball Valves?

- Aug 27, 2025

Sealing Performance and Maintenance of Ball Valves

- Nov 12, 2025

Related Articles from China Manufacturers

The Differences Between Ball Valves and Globe Valves

- May 10, 2019

API 6D Trunnion Mounted Ball Valve

- May 19, 2020

API 6D Floating Ball Valves

- Aug 16, 2022

API 6D Super Big Size Ball valves

- Aug 21, 2020

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Address: Dongou Industrial Zone, Oubei, Wenzhou, Zhejiang, China

- Phone: 86 577 5798 7171

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/astm-a182-f51-trunnion-ball-valves-api-6d-12-inch-1500-lb.html

-320x320.webp)