ASTM A182 F304 Metal Seated Ball Valve, API 6D, 2 IN, CL600

Product Name: ASTM A182 F304 Ball Valve, Metal Seated

Design Standard: API 6D, BS 5351

Body Material: ASTM A182 F304

Size: 2 Inch, DN50

Pressure: Class 600 LB, PN100

End Connection: RF

Operation: Bare Stem

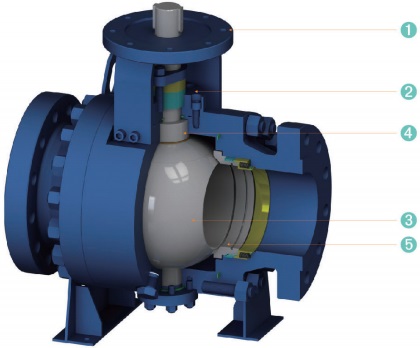

The metal-seated ball valve features a robust metal-to-metal sealing mechanism for superior performance in demanding environments. Designed to handle extreme temperatures and pressures, this valve employs advanced hardening technologies for the ball and seat, including HVOF coating, nickel-base alloy spray welding, cobalt-base hard alloy welding, and others. These treatments ensure excellent heat resistance, wear resistance, and impact durability, with sealing face materials tolerating up to 980°C. The stainless steel seat is reinforced with stellite alloy pile-up welding, while the ball undergoes specialized treatments like hard chrome plating, vacuum coating, and tungsten-titanium alloy welding for enhanced heat and wear resistance. KOSEN’s precision manufacturing ensures high-accuracy and ultra-smooth ball surfaces. The valve also incorporates a spring-prepressing seat for reliable sealing and stable operating torque, ensuring safety and operational flexibility.

Technical Specifications

» Size Range: NPS 2-36 Inch (DN50-DN900)

» Design Pressure: Class 150-900 LB (PN10-PN160)

» Materials:

Carbon Steel, Stainless Steel, Duplex Steel, or Special Alloys (ASTM A105N, A350 LF2, A182 F304, F304L, F316, F316L, F51, etc.)

Trim Materials: 13% Cr, SS 304, SS 304L, SS 316, SS 316L, and others

» End Connections: Flanged RF, RTJ, or Welded BW

» Operation: Manual handle, worm gear, electric, or pneumatic actuators

» Temperature Range: -29°C to 300°C

» Medium: Suitable for water, gas, and oil

Standards

» Design and Manufacture: API 6D, BS 5351, ASME B16.34

» Face-to-Face Dimensions: ASME B16.10

» Flanged Connections: ASME B16.5, ASME B16.47

» Butt Welded Ends: ASME B16.25

» Fire Safety: API 607, API 6A

» Testing and Inspection: API 598, API 6D

Product Features

» Advanced Ball and Seat Hardening: Ensures exceptional heat, wear, and impact resistance.

» Fireproof Structure Design: Provides safety in high-temperature environments.

» Double Block and Bleed: Available in trunnion-mounted configurations for enhanced functionality.

» Reliable Sealing Performance: Ensures zero leakage even under extreme conditions.

» Blowout-Proof Stem: Prevents accidents caused by stem failure.

» Corrosion and Stress Resistance: Suitable for challenging chemical and sour gas applications.

» Flexible Operation: Options for manual, electric, and pneumatic actuation.

» Customizable Features: Locking devices, stem extensions, and ISO 5211 direct mounting.

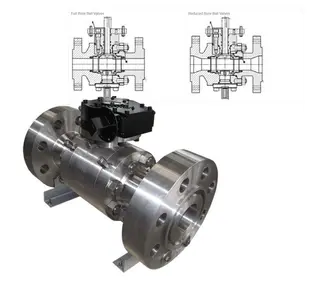

» Flow Options: Full port or reduced bore configurations available.

Send your message to this supplier

Related Articles from the Supplier

Metal to Metal Ball Valves Characteristics

- Dec 14, 2024

What To Pay Attention To In Ball Valve Maintenance

- Dec 14, 2024

Installation of welded ball valve

- Dec 14, 2024

Full Bore Ball Valves vs. Reduced Bore Ball Valves

- Oct 27, 2025

Ball Valve Maintenance And Maintenance Details

- Dec 14, 2024

Pneumatic Ball Valve Selection Guide

- Sep 15, 2025

Related Articles from China Manufacturers

API 6D Metal Seated Ball Valve

- May 22, 2020

Top Entry Metal Seated Butterfly Valves

- Sep 25, 2021

Lift Metal Seated Plug Valves

- Dec 15, 2022

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Address: Dongou Industrial Zone, Oubei, Wenzhou, Zhejiang, China

- Phone: 86 577 5798 7171

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/astm-a182-f304-metal-seated-ball-valve-api-6d-2-in-cl600.html