What's the Benefit of Aluminum Alloy Die Casting after Infiltration Process?

Aluminum alloy die casting infiltration is a new type of casting process, the main principle is to use polystyrene foam to make exactly the same foam model as casts, and then brushed aluminum alloy die casts which was impregnated with special refractory coating, drying, packing, pouring, the metal solution replace the foam model until the finish of castings. At last, the used sand will be changed into dry sand with cleanness and appropriate temperature after cooling treatment, removing dust, static, magnetic separation. There are white area, red area and black area.

The main three advantages of aluminum alloy die casting infiltration

Firstly, cost savings

1. The mold that was used for infiltration could be used for lifetime and almost at no loss, which could reduce or spare the cost of the mold.

2. Aluminum alloy die casting infiltration got rid of traditional core setting process, so it was not only labor saving, but also reduced the manufacturing costs.

3. Aluminum alloy die casting infiltration industry has developed from male workers to female workers. This has not only reduced the labor, but also decreased the cost of wages in a way.

4. Aluminum alloy die casting infiltration can be recycled, its loss is 2%-5%.

Secondly, improving efficiency and yield

1. Aluminum alloy die casting infiltration foam model is the mechanical foaming, it could ensure the quality of the model, and the production speed is quite rapid.

2. Aluminum alloy die casting infiltration process simplifies the time-consuming steps of traditional process.

3. Aluminum alloy die casting infiltration is a box for multiple pourings, and could also pour a number of boxes until the metal solution is completely finished.

Thirdly, improve product quality

1. Aluminum alloy die casting infiltration doesn’t need to shape the core, so we can eliminate any defects or waste products.

2. No need for mold closing so as to prevent defects of trimming and burr or waste products, and improve product accuracy.

3. Most of the paint can naturally fall off after the furnace, because of no trimming and burr, the time for cleaning up would be reduced over 50%, which could the cost of cleaning up.

4. Aluminum alloy die casting infiltration adopts dry sand solid vacuum-assist pouring, which excludes or reduces defects of sand holes and air holes.

5. Aluminum alloy die casting infiltration is gasified from foam model, the model was replaced by metal solution with prototype. So its surface finish and dimensional accuracy are close to precision die casting.

The main three advantages of aluminum alloy die casting infiltration

Firstly, cost savings

1. The mold that was used for infiltration could be used for lifetime and almost at no loss, which could reduce or spare the cost of the mold.

2. Aluminum alloy die casting infiltration got rid of traditional core setting process, so it was not only labor saving, but also reduced the manufacturing costs.

3. Aluminum alloy die casting infiltration industry has developed from male workers to female workers. This has not only reduced the labor, but also decreased the cost of wages in a way.

4. Aluminum alloy die casting infiltration can be recycled, its loss is 2%-5%.

Secondly, improving efficiency and yield

1. Aluminum alloy die casting infiltration foam model is the mechanical foaming, it could ensure the quality of the model, and the production speed is quite rapid.

2. Aluminum alloy die casting infiltration process simplifies the time-consuming steps of traditional process.

3. Aluminum alloy die casting infiltration is a box for multiple pourings, and could also pour a number of boxes until the metal solution is completely finished.

Thirdly, improve product quality

1. Aluminum alloy die casting infiltration doesn’t need to shape the core, so we can eliminate any defects or waste products.

2. No need for mold closing so as to prevent defects of trimming and burr or waste products, and improve product accuracy.

3. Most of the paint can naturally fall off after the furnace, because of no trimming and burr, the time for cleaning up would be reduced over 50%, which could the cost of cleaning up.

4. Aluminum alloy die casting infiltration adopts dry sand solid vacuum-assist pouring, which excludes or reduces defects of sand holes and air holes.

5. Aluminum alloy die casting infiltration is gasified from foam model, the model was replaced by metal solution with prototype. So its surface finish and dimensional accuracy are close to precision die casting.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

What's the difference between CRI and CCT

- Aug 26, 2015

What's the Best Material for Sanitary Napkins?

- Sep 05, 2024

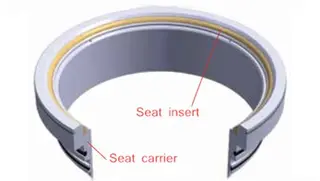

Related Products Mentioned in the Article

Supplier Website

Source: https://www.china-die-casting.com/what-s-the-benefit-of-aluminum-alloy-die-casting-after-infiltration-process.html