Pouring Processes & Hardness Requirements of Aluminum Alloy Die Casts

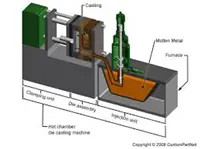

Aluminum alloy die casting manufacturers must ensure the quality of their products in the production processes. In order to obtain the metal parts through die casting during the operation, we should pay more attention to the die casting processes. First, we need to smelt metal materials, and then inject them into the molds by effectively pouring.

The most important of aluminum alloy die castings is to effectively ensure the quality of die casting products. Effectively improving the production efficiency and reducing the production costs are relatively important. Therefore, we need to determine the plans, to do good analyses, and to try to avoid any errors in the die casting processes.

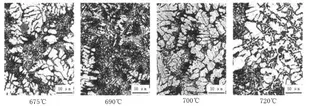

The quality of aluminum alloy die castings has a great impact on the performance of mechanical products. During the operations, we need to effectively guarantee the quality of die casts; to some extent, the operation of the products and the used materials are the factors which can not be ignored; we also need to constantly improve the technique of the technicians, which is one of the most important key points.

We can adopt top gating systems for aluminum alloy die casts in the die casting processes, in which the heat losses of the metal liquid are little. The whole system uses a little portion of metal liquid, and there is a reasonable heat distribution in the cavities, which is more conducive to directional solidification and feedings of die casts.

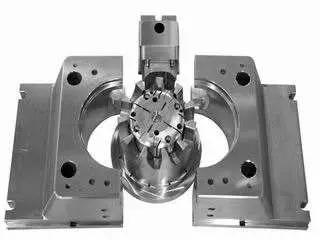

Aluminum alloy die casts have different hardness and strength in the die casting processes. The designs and die casting techniques are the most critical for die casting products. If we don't do a good job on these, they will affect the quality of die casts to a certain degree.

In the bottom gating system of aluminum alloy die casting, the metal liquid goes through the cavities and smoothly fills the molds from top to bottom under the action of the metals' gravity, which is good for the exhaust of the equipment and drossing. However, heat distribution of the whole cavity is extremely unreasonable, which can not finish the required directional solidification steps of gravity castings.

The most important of aluminum alloy die castings is to effectively ensure the quality of die casting products. Effectively improving the production efficiency and reducing the production costs are relatively important. Therefore, we need to determine the plans, to do good analyses, and to try to avoid any errors in the die casting processes.

The quality of aluminum alloy die castings has a great impact on the performance of mechanical products. During the operations, we need to effectively guarantee the quality of die casts; to some extent, the operation of the products and the used materials are the factors which can not be ignored; we also need to constantly improve the technique of the technicians, which is one of the most important key points.

We can adopt top gating systems for aluminum alloy die casts in the die casting processes, in which the heat losses of the metal liquid are little. The whole system uses a little portion of metal liquid, and there is a reasonable heat distribution in the cavities, which is more conducive to directional solidification and feedings of die casts.

Aluminum alloy die casts have different hardness and strength in the die casting processes. The designs and die casting techniques are the most critical for die casting products. If we don't do a good job on these, they will affect the quality of die casts to a certain degree.

In the bottom gating system of aluminum alloy die casting, the metal liquid goes through the cavities and smoothly fills the molds from top to bottom under the action of the metals' gravity, which is good for the exhaust of the equipment and drossing. However, heat distribution of the whole cavity is extremely unreasonable, which can not finish the required directional solidification steps of gravity castings.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Basic Principles of Pouring System Design

- Jun 28, 2017

Design of Injection Molds' Pouring Systems

- Jun 12, 2017

The Importance of Locations of Pouring Gates

- Sep 24, 2022

Related Products Mentioned in the Article

Supplier Website

Source: https://www.china-die-casting.com/pouring-processes-hardness-requirements-of-aluminum-alloy-die-casts.html