Effects of Mold Designs on Quality of Aluminum Die Casts (Part Three)

4. Designs of discharge systems

Overflow boxes and discharge passages with enough overflowing areas should be set up for molds, which is very important to ensure quality of die casts. People often overlook the problem of molten metal blocking the overflow passages too early. Reasonable structures should be adopted to make molten metal firstly flow into the deeper parts of overflow boxes, ensuring discharge vents not being blocked for the longest time. In addition, ejector rods should be set up for overflow boxes to remove the metals in overflow boxes.

5. Molds' temperatures

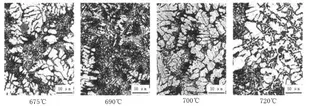

The temperature of the die casting mold is an important factor in the quality of the die cast. Inappropriate temperatures not only can affect internal and external quality of die casts (defects such as blowholes, shrinkage cavities, shrinkage porosity, mold sticking and coarse grains will appear), but also can affect dimensional accuracy of die casts, and they can even cause deformation of die casts, resulting in cracks of die casting molds and burrs like net being difficult to be removed on surfaces of die casts, which will influence quality of die casts' appearance. Taking aluminum alloys for an example, when temperatures of alloys are from 670 to 710℃, the alloys are poured into the die casts. In the long-term practice of production, it is concluded that the optimum temperature of the mold should be controlled at 40% of the molten alloy's temperature. Temperatures of aluminum alloy die casting molds should be from 230 to 280℃. Temperature of the mould in this range is conducive to obtain the die cast with high quality and production.

Molds are generally not heated by gases or electricity. Preheating and cooling devices are adopted for molds. Oil is used as the medium for the device based on the requirement, and the device is used for preheating and cooling the mold.

6. Determinations of molded parts' sizes

When die casting parts' dimensions are calculated, shrinkage rates of the selected die casting materials should conform to shrinkage rates of the finished die casting products. Otherwise, the die casting product will be unqualified. If necessary, calculate the dimension of the die casting part after actual measurement of the die. For die casting products with high accuracy, thermal expansion of die casting parts' materials, storage and usage environment which can affect dimensional accuracy of die casting products should be taken into account.

7. Determinations of parting surfaces' positions

Positions of parting surfaces will influence mold processing, discharge and demoulding of the die casting products. Generally, the parting surface can leave a line on the die casting products, affecting surface quality and dimensional accuracy of die casting products. Therefore, when the prating surface is designed, the parting surface should be set up on the die casting surface where the requirement of the surface quality is not high or the dimensional accuracy is not high besides considering discharge, mold processing and demoulds of the die casting products.

Overflow boxes and discharge passages with enough overflowing areas should be set up for molds, which is very important to ensure quality of die casts. People often overlook the problem of molten metal blocking the overflow passages too early. Reasonable structures should be adopted to make molten metal firstly flow into the deeper parts of overflow boxes, ensuring discharge vents not being blocked for the longest time. In addition, ejector rods should be set up for overflow boxes to remove the metals in overflow boxes.

5. Molds' temperatures

The temperature of the die casting mold is an important factor in the quality of the die cast. Inappropriate temperatures not only can affect internal and external quality of die casts (defects such as blowholes, shrinkage cavities, shrinkage porosity, mold sticking and coarse grains will appear), but also can affect dimensional accuracy of die casts, and they can even cause deformation of die casts, resulting in cracks of die casting molds and burrs like net being difficult to be removed on surfaces of die casts, which will influence quality of die casts' appearance. Taking aluminum alloys for an example, when temperatures of alloys are from 670 to 710℃, the alloys are poured into the die casts. In the long-term practice of production, it is concluded that the optimum temperature of the mold should be controlled at 40% of the molten alloy's temperature. Temperatures of aluminum alloy die casting molds should be from 230 to 280℃. Temperature of the mould in this range is conducive to obtain the die cast with high quality and production.

Molds are generally not heated by gases or electricity. Preheating and cooling devices are adopted for molds. Oil is used as the medium for the device based on the requirement, and the device is used for preheating and cooling the mold.

6. Determinations of molded parts' sizes

When die casting parts' dimensions are calculated, shrinkage rates of the selected die casting materials should conform to shrinkage rates of the finished die casting products. Otherwise, the die casting product will be unqualified. If necessary, calculate the dimension of the die casting part after actual measurement of the die. For die casting products with high accuracy, thermal expansion of die casting parts' materials, storage and usage environment which can affect dimensional accuracy of die casting products should be taken into account.

7. Determinations of parting surfaces' positions

Positions of parting surfaces will influence mold processing, discharge and demoulding of the die casting products. Generally, the parting surface can leave a line on the die casting products, affecting surface quality and dimensional accuracy of die casting products. Therefore, when the prating surface is designed, the parting surface should be set up on the die casting surface where the requirement of the surface quality is not high or the dimensional accuracy is not high besides considering discharge, mold processing and demoulds of the die casting products.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Supplier Website

Source: https://www.china-die-casting.com/effects-of-mold-designs-on-quality-of-aluminum-die-casts-part-three.html