China Die Casting Mold Enterprises succeeding in making automobiles lightweight

In order to cope with increasingly stringent fuel economy regulations, light weights of automobiles are general trends. The experimental results show that when weights of automobiles are reduced by 10%, fuel efficiency can be increased by 6% to 8%; curb weights are reduced by every 100 kilograms, fuel consumption per hundred kilometers can be reduced by 0.3 to 0.6 liters. From the view of costs, if we reduce one kilogram of the vehicles' weights, we will reduce the costs about 10 dollars. Lightweight automobiles have become the world's automobile development trend due to requirements of environmental protection and energy saving. At present, the measure used to make automobile lightweight is mainly adopting lightweight materials like magnesium alloys and aluminum alloys.

Lightweight materials of automobiles

(1) Casting aluminum alloys

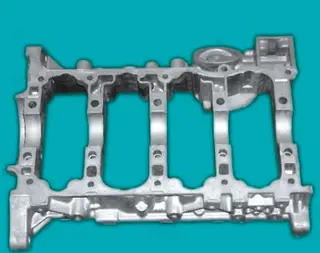

The automobile industry is the main market for aluminum castings. Taking Japan as an example, 76% of aluminum castings and 77% of aluminum die castings in Japan are automobile castings. Aluminum alloy castings are mainly applied to engine cylinder blocks, cylinder covers, pistons, rocker arms, clutch housings, wheels, brake parts, handles, etc.

(2) Magnesium alloys

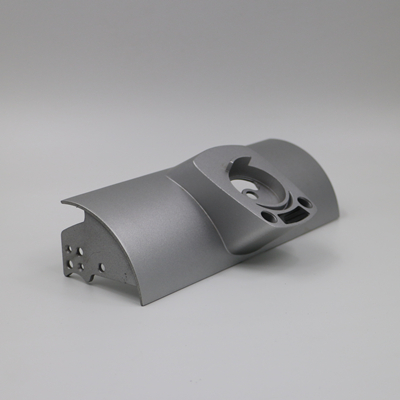

The density of magnesium is about two thirds of aluminum, and magnesium is the lightest metal in practical applications. Magnesium alloys have strong shock absorption and good machinability, which makes them very suitable for manufacturing automobile parts. Most of magnesium alloys are used for automobiles as die casts, and production efficiency of magnesium die casts is 30% to 50% higher than aluminum die casts'. The newly developed pore free die casting process can produce magnesium die casts without blowholes and with heat treatment.

The earliest example of magnesium die castings used in automobiles is the wheel rim. Magnesium alloys which are tried out on or used for automobiles are clutch housings, clutch pedals, brake pedal fixed trestle, instrument panel structures, seats, gearbox housings, cylinder covers, etc. Compared with the traditional upper brackets of steering columns made of zinc, weights of the magnesium parts are reduced by 65%; compared with the traditional steel steering wheel cores, weights of magnesium parts are reduced by 45%; compared with aluminum cylinder covers, weights of magnesium parts are reduced by 30%; compared with the traditional steel stamping welded brake pedal fixed trestles, the overall magnesium castings' weights are reduced by 40%, while magnesium castings' rigidity can also be improved.

In recent years, lightweight structural components have become a hot topic in the die casting industry driven by the trend of lightweight vehicles. Especially for new energy automobiles, electrification, intelligence and light weight are the main directions in the future. Lightweight materials such as aluminum alloys, magnesium alloys, etc. have performance of being lightweight, strong shock absorption, good castability, automated production capacity, and moulds made of the lightweight materials can have long service lives and dimensional stability. Aluminum alloys and magnesium alloys are not only the most suitable materials for die casting auto parts, but also are the most effective lightweight materials for automobiles.

Lightweight materials of automobiles

(1) Casting aluminum alloys

The automobile industry is the main market for aluminum castings. Taking Japan as an example, 76% of aluminum castings and 77% of aluminum die castings in Japan are automobile castings. Aluminum alloy castings are mainly applied to engine cylinder blocks, cylinder covers, pistons, rocker arms, clutch housings, wheels, brake parts, handles, etc.

(2) Magnesium alloys

The density of magnesium is about two thirds of aluminum, and magnesium is the lightest metal in practical applications. Magnesium alloys have strong shock absorption and good machinability, which makes them very suitable for manufacturing automobile parts. Most of magnesium alloys are used for automobiles as die casts, and production efficiency of magnesium die casts is 30% to 50% higher than aluminum die casts'. The newly developed pore free die casting process can produce magnesium die casts without blowholes and with heat treatment.

The earliest example of magnesium die castings used in automobiles is the wheel rim. Magnesium alloys which are tried out on or used for automobiles are clutch housings, clutch pedals, brake pedal fixed trestle, instrument panel structures, seats, gearbox housings, cylinder covers, etc. Compared with the traditional upper brackets of steering columns made of zinc, weights of the magnesium parts are reduced by 65%; compared with the traditional steel steering wheel cores, weights of magnesium parts are reduced by 45%; compared with aluminum cylinder covers, weights of magnesium parts are reduced by 30%; compared with the traditional steel stamping welded brake pedal fixed trestles, the overall magnesium castings' weights are reduced by 40%, while magnesium castings' rigidity can also be improved.

In recent years, lightweight structural components have become a hot topic in the die casting industry driven by the trend of lightweight vehicles. Especially for new energy automobiles, electrification, intelligence and light weight are the main directions in the future. Lightweight materials such as aluminum alloys, magnesium alloys, etc. have performance of being lightweight, strong shock absorption, good castability, automated production capacity, and moulds made of the lightweight materials can have long service lives and dimensional stability. Aluminum alloys and magnesium alloys are not only the most suitable materials for die casting auto parts, but also are the most effective lightweight materials for automobiles.

Send your message to this supplier

Related Articles from the Supplier

China Die Casting Industry Facing with Challenges

- Feb 19, 2016

China Import and Export Fair

- Aug 01, 2016

Related Articles from China Manufacturers

Hot forging.Die forging from China

- Nov 28, 2024

China Import and Export Fair, The 120th Canton Fair

- Oct 27, 2016

China Automobile Mould Industry Meets Great Boom

- Oct 27, 2016

China Smart Phones Make Favorable Sales Volume

- Oct 27, 2016

Related Products Mentioned in the Article

Supplier Website

Source: https://www.china-die-casting.com/china-die-casting-mold-enterprises-succeeding-in-making-automobiles-lightweight.html