Multi-Turn Electric Gate Valves Drive Efficiency in Industrial Pipeline Systems

Introduction

As global industries continue to move toward digitalization, automation, and smarter infrastructure, traditional manual valves are rapidly being replaced by intelligent, electrically actuated solutions. Among the most important of these are multi-turn electric gate valves—a critical component in pipelines where tight shutoff, reliable isolation, and remote operation are essential.

From power generation and oil and gas to water treatment, shipbuilding, and mining, multi-turn electric gate valves are becoming the backbone of automated flow control systems. By combining the proven sealing performance of gate valves with advanced electric actuators, these devices enable operators to control large-diameter pipelines safely, accurately, and efficiently from control rooms or remote monitoring centers.

This article explores what multi-turn electric gate valves are, how they work, their core features, key advantages, applications across industries, technical considerations, and emerging trends that are shaping the future of valve automation.

What Is a Multi-Turn Electric Gate Valve?

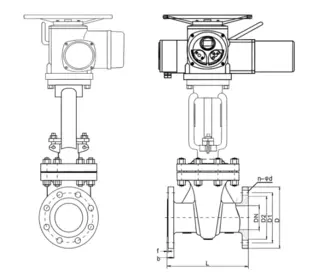

A multi-turn electric gate valve is a gate valve operated by a multi-turn electric actuator. Unlike manual gate valves that require handwheels or gearboxes, electric gate valves use electric motors to drive the stem through multiple revolutions, allowing the valve to fully open or fully close at the push of a button or through an automated control system.

In a traditional gate valve, the gate (or wedge) moves linearly up and down to start or stop flow. When combined with a multi-turn electric actuator, the motion of the valve stem is powered by an electric motor that rotates over several turns, converting rotary motion into linear travel. This design is particularly suited for:

- Large-diameter pipelines

- High-pressure systems

- Hard-to-reach or hazardous environments

- Applications requiring frequent or remote operation

By eliminating the need for manual intervention, multi-turn electric gate valves improve operational efficiency, enhance worker safety, and integrate seamlessly into modern industrial automation systems.

How Multi-Turn Electric Gate Valves Work

The operation of a multi-turn electric gate valve is based on the precise coordination between the valve body and the electric actuator.

Electrical Input: When a control signal is sent—either from a local control panel, PLC, DCS, or SCADA system—the actuator receives power.

Motor Activation: The electric motor inside the actuator begins rotating, delivering torque to the valve stem.

Stem Movement: Through a gearbox mechanism, the actuator converts rotary motion into the linear movement required to raise or lower the gate.

Flow Control:

When the gate is fully lifted, the valve is open, allowing unrestricted flow.

When the gate is fully lowered, it blocks the flow path, providing tight shutoff.

Position Feedback: Sensors and limit switches within the actuator confirm the valve's position and relay status back to the control system.

Because gate valves are designed primarily for on/off service rather than throttling, electric actuation ensures precise, repeatable movement to the fully open or fully closed position without human error.

Key Features of Multi-Turn Electric Gate Valves

Modern electric gate valves are engineered with advanced mechanical and electronic features to meet the needs of demanding industrial environments.

Wide Torque Range

Multi-turn electric actuators typically offer a torque range from 50 Nm to 10,000 Nm or higher, enabling them to operate valves of various sizes and pressure classes. This wide range makes them suitable for both small-bore process lines and large transmission pipelines.

Multiple Power Supply Options

To ensure compatibility with diverse operating environments, actuators are available with:

- Three-phase AC motors for heavy-duty industrial use

- Single-phase AC motors for lighter applications

- DC motors for battery-powered or mobile installations

This flexibility allows deployment in remote sites, offshore platforms, and emergency backup systems.

Compliance with International Standards

Electric gate valves are manufactured to meet major international valve standards, including:

ANSI / ASME

DIN

JIS

GB

This ensures compatibility with pipelines and systems across global markets, simplifying integration and replacement.

Excellent Sealing Performance

High-quality gate designs offer:

- Low fluid resistance when fully open

- Tight shutoff in the closed position

- Minimal pressure drop across the valve

Sealing surfaces made from stainless steel or hard alloys provide excellent wear resistance and long service life, even in abrasive or corrosive environments.

Bi-Directional Flow Capability

Most electric gate valves are designed for double flow direction, allowing installation without concern for flow orientation. This simplifies piping design and improves system flexibility.

Advanced Control Interfaces

Modern actuators support multiple communication protocols, including:

- Modbus

- Profibus

- HART

- DeviceNet

- Fieldbus systems

These interfaces allow seamless integration into automated control architectures, enabling real-time monitoring, diagnostics, and centralized operation.

Material Options for Diverse Applications

To suit different media and environmental conditions, electric gate valves are available in materials such as:

- Carbon steel (e.g., WCB)

- Stainless steel

- Cast iron

- Alloy steel

This variety ensures compatibility with applications ranging from clean water to corrosive chemicals and high-temperature steam.

Advantages of Multi-Turn Electric Gate Valves

The adoption of electric actuation provides significant benefits compared with manual or pneumatic alternatives.

1. Remote Operation and Automation

Electric gate valves can be controlled from:

- Central control rooms

- Distributed control systems (DCS)

- SCADA platforms

- Cloud-based monitoring systems

This reduces the need for on-site personnel and enables rapid response to changing process conditions.

2. Improved Safety

In hazardous environments—such as high-pressure pipelines, toxic chemical handling, or offshore platforms—manual valve operation exposes workers to risk. Electric actuators allow operators to remain in safe locations while controlling critical equipment.

3. Consistent and Accurate Operation

Electric actuators deliver precise torque and position control, ensuring that valves reach the correct end position every time. This minimizes the risk of partial closure, leakage, or mechanical damage caused by over-torquing.

4. Reduced Labor and Maintenance Costs

Automated operation eliminates the need for manual intervention and reduces wear associated with improper handling. With built-in diagnostics and remote monitoring, maintenance can be scheduled proactively rather than reactively.

5. Long Service Life

With robust materials, hardened sealing surfaces, and protected electronic components, multi-turn electric gate valves are designed for long-term reliability in harsh industrial conditions.

Applications Across Key Industries

Power Generation

In thermal, nuclear, and renewable power plants, electric gate valves are widely used for:

- Boiler feedwater isolation

- Cooling water systems

- Steam distribution

- Condensate handling

The ability to operate remotely and integrate with plant control systems is essential for maintaining safe and stable operations.

Oil and Gas

From upstream production to midstream transportation and downstream refining, electric gate valves play a vital role in:

- Pipeline isolation

- Process unit shutdowns

- Tank farm operations

- Offshore platform systems

High torque capability, explosion-proof actuator designs, and reliable sealing make them suitable for demanding oil and gas environments.

Water and Wastewater Treatment

Municipal and industrial water facilities rely on electric gate valves for:

- Main pipeline isolation

- Pump station control

- Sludge and wastewater handling

- Flood control and drainage systems

Remote operation allows operators to respond quickly to emergencies such as pipe bursts or flooding events.

Mining and Metals

In mining, iron and steel production, and mineral processing, these valves are used in:

- Slurry pipelines

- Cooling circuits

- Chemical dosing systems

- Tailings management

The combination of robust construction and automated control ensures reliable performance in abrasive and high-load conditions.

Paper and Pulp

Paper mills require precise control over water, steam, chemicals, and pulp flow. Electric gate valves are used in:

- Process water systems

- Chemical recovery units

- Steam distribution

- Effluent treatment

Their low resistance when fully open helps maintain efficient flow and reduce energy consumption.

Shipbuilding and Marine Applications

In shipyards and marine systems, electric gate valves are installed in:

- Ballast water systems

- Cooling circuits

- Fuel and lubrication lines

- Firefighting networks

Remote control and corrosion-resistant materials are critical in marine environments.

Technical Considerations When Selecting a Multi-Turn Electric Gate Valve

Choosing the right electric gate valve requires careful evaluation of several technical parameters.

Torque Requirements

The actuator must provide sufficient torque to overcome:

- Line pressure

- Packing friction

- Valve seating forces

Undersized actuators can lead to incomplete operation, while oversized units may cause mechanical stress.

Voltage and Power Supply

Determine whether the site requires:

AC or DC power

Single-phase or three-phase motors

For remote or mobile installations, DC-powered actuators with battery systems may be preferable.

Environmental Conditions

Consider factors such as:

- Ambient temperature

- Humidity and dust levels

- Corrosive atmospheres

- Explosion-hazard zones

For hazardous locations, actuators should meet relevant explosion-proof or hazardous-area certifications.

Control and Communication

Modern plants require seamless integration with automation systems. Ensure that the actuator supports:

- Required communication protocols

- Remote diagnostics

- Position feedback and alarm outputs

This enhances system transparency and operational efficiency.

Valve Material and Media Compatibility

The valve body and sealing materials must be compatible with the working medium—whether it is water, steam, oil, gas, chemicals, or slurry—to prevent corrosion, erosion, or contamination.

Maintenance and Lifecycle Performance

One of the key advantages of electric gate valves is their relatively low maintenance requirements. However, best practices include:

- Regular inspection of actuator seals and wiring

- Periodic testing of limit switches and torque settings

- Lubrication of mechanical components as recommended by the manufacturer

With proper care, these valves can provide decades of reliable service, making them a cost-effective solution for critical infrastructure.

The Role of Digitalization and Smart Valve Technology

The integration of digital technologies is transforming valve automation.

Remote Monitoring and Diagnostics

Smart actuators can transmit real-time data on:

- Valve position

- Torque levels

- Motor temperature

- Cycle counts

This enables predictive maintenance and reduces unplanned downtime.

Integration with Industrial IoT

Electric gate valves are increasingly connected to Industrial Internet of Things (IIoT) platforms, allowing operators to:

- Monitor performance across multiple sites

- Analyze usage patterns

- Optimize maintenance schedules

- Improve asset management

Cybersecurity and System Protection

As valves become more connected, cybersecurity becomes essential. Manufacturers are now incorporating secure communication protocols and access controls to protect critical infrastructure from unauthorized access.

Market Trends and Future Outlook

The global demand for electric actuated valves is rising rapidly due to:

- Increased automation in manufacturing and utilities

- Expansion of energy infrastructure

- Growth in water and wastewater treatment projects

- Stricter safety and environmental regulations

Shift Toward Smart Infrastructure

Governments and industries are investing in smart grids, intelligent water networks, and automated industrial plants, all of which rely heavily on electrically actuated valves.

Energy Efficiency and Sustainability

Electric actuation is increasingly preferred over pneumatic systems because it:

- Eliminates compressed air losses

- Reduces energy consumption

- Supports integration with renewable energy sources

Customization and Modular Design

Manufacturers are offering more modular actuator designs, allowing users to:

- Upgrade torque capacity

- Add communication modules

- Customize enclosures for harsh environments

This modularity enhances flexibility and future-proofs installations.

Conclusion: Why Multi-Turn Electric Gate Valves Are Essential for Modern Industry

Multi-turn electric gate valves represent the convergence of proven mechanical valve design and advanced electrical automation. By enabling remote operation, improving safety, reducing labor requirements, and integrating seamlessly into modern control systems, they have become indispensable in today's industrial landscape.

From power plants and oil refineries to water treatment facilities, mining operations, and marine systems, these valves provide the reliability, precision, and efficiency required to manage critical processes. As industries continue to embrace digital transformation and smart infrastructure, the role of electrically actuated gate valves will only grow.

With features such as wide torque ranges, multiple power options, international standard compliance, advanced communication protocols, and robust material choices, multi-turn electric gate valves are not just components—they are strategic assets for safe, efficient, and future-ready flow control.

Send your message to this supplier

Related Articles from the Supplier

Multi-Turn Electric Actuator: An In-Depth Look

- Dec 20, 2024

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Supplier Website

Source: https://china-control-valves.com/news/multi-turn-electric-gate-valves-drive-efficiency-in-industrial-pipeline-systems.html