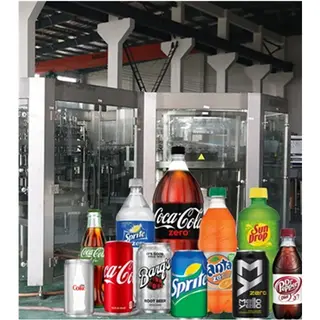

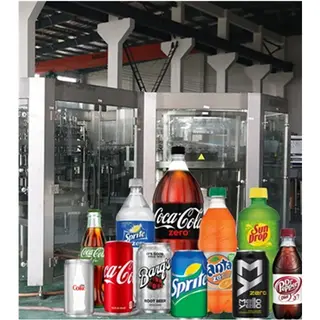

3 in 1 Monoblock Carbonated Drink Bottling Machine

Key Specifications / Features

3 in 1 Monoblock Carbonated Drink Bottling Machine Supplier: Rotary Carbonated Drink Bottling Machine, 3 in 1 Monoblock, 5000-28000 BPH, 200-2200 ml, SUS 304.

Request a quote

Detail Information

Name: Stainless Steel 304 Soda Water Sparkling Water Gas.

Type: Filling Machine, Volumetric Filling Machine.

Automatic Grade: Automatic.

Material Type: Liquid.

Filling Valve Head: Multi-Head.

Feed Cylinder Structure: Single-Room Feeding.

Dosing Device: Surface Type.

Filling Principle: Pressure.

Packaging Container Lifting Structure: Pneumatic Lifting.

Structure: Rotary.

Packaging: Bottle.

Packaging Material: Plastic.

Capacity: 5000-28000 BPH.

Bottle Volume: 200ml-2200ml.

Application: Carbonated Soft Drinks.

Filling Accuracy: 0.5%.

Machine Material: SUS 304/SUS 316.

Machine Structure: Rinser, Filler, Capper 3 in 1 Monoblock.

Specification: 2400 x 1650 x 2500mm.

Application: Carbonated Soft drinks, soda water, sparkling water, CO2 gas water, fizzy water, CSD, fizzy drinks, gas drinks, cola, carbonating water, carbonate water.

The carbonated soft drinks water machinery combiblock is composed by:

RINSER-FILLER-CAPPER 3 in 1 monoblock.

Equipment structure:

1. Rinsing system: Combined with rotary trays with the clamp, water distributing trays, water tank and rinsing pumps.

2. Filling system: Combined with the hydraulic, filling valve, the controlling ring, and the lift cylinder.

3. Capping system: Combined with the capper, cap sorter and cap falling track.

4. Driving system: Combined with main motors and gears.

5. Bottle transmitting system: Combined with the air conveyor, steel starwheels and neck supporting carrier plates.

6. Electrical controlling system: this part is frequently inverted, PLC controlled and touch screen operated.

Type: Filling Machine, Volumetric Filling Machine.

Automatic Grade: Automatic.

Material Type: Liquid.

Filling Valve Head: Multi-Head.

Feed Cylinder Structure: Single-Room Feeding.

Dosing Device: Surface Type.

Filling Principle: Pressure.

Packaging Container Lifting Structure: Pneumatic Lifting.

Structure: Rotary.

Packaging: Bottle.

Packaging Material: Plastic.

Capacity: 5000-28000 BPH.

Bottle Volume: 200ml-2200ml.

Application: Carbonated Soft Drinks.

Filling Accuracy: 0.5%.

Machine Material: SUS 304/SUS 316.

Machine Structure: Rinser, Filler, Capper 3 in 1 Monoblock.

Specification: 2400 x 1650 x 2500mm.

Application: Carbonated Soft drinks, soda water, sparkling water, CO2 gas water, fizzy water, CSD, fizzy drinks, gas drinks, cola, carbonating water, carbonate water.

The carbonated soft drinks water machinery combiblock is composed by:

RINSER-FILLER-CAPPER 3 in 1 monoblock.

Equipment structure:

1. Rinsing system: Combined with rotary trays with the clamp, water distributing trays, water tank and rinsing pumps.

2. Filling system: Combined with the hydraulic, filling valve, the controlling ring, and the lift cylinder.

3. Capping system: Combined with the capper, cap sorter and cap falling track.

4. Driving system: Combined with main motors and gears.

5. Bottle transmitting system: Combined with the air conveyor, steel starwheels and neck supporting carrier plates.

6. Electrical controlling system: this part is frequently inverted, PLC controlled and touch screen operated.

Send your message to this supplier

FAQs

Yes, 3.2 certificates are available at an additional cost. We work with reputable third-party inspection agencies (TPI) such as BV, TUV, SGS, or LR, who will inspect the valves and issue signed certificates provided with the shipment.