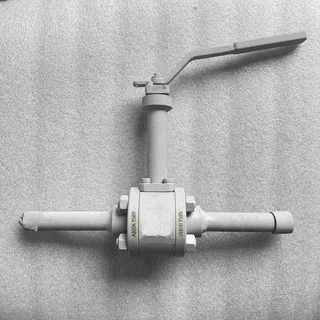

Three Pieces Stainless Steel Ball Valve, 1/8-4 Inch

Key Specifications / Features

Three Pieces Ball Valve Fabricator: Stainless Steel Ball Valve, Three Pieces, SS304, SS316, CF8, CF8M, 1/8-4 Inch, 1000, 2000, 3000, 200, 800 PSI, NPT.

Request a quote

Detail Information

The three pieces stainless steel ball valve has female connection and welding, also called welding ball valve. It can be equipped with a gallery and an actuator.

Specification:

The three piece stainless steel ball valve can be closed tightly only by rotating 90 degrees with a small rotating torque. The fully equal body cavity provides a small, straight flow path for the medium. Ball valves are generally considered to be the most suitable for direct closure, but recently, the ball valve is designed to be used for throttling and controlling flow. The main characteristics of ball valves are compact structure, easy operation and maintenance. They are not only applicable to water, solvent, acid and gas and other general work media, but also for media with severe working conditions, such as oxygen, hydrogen peroxide, methane and ethylene. The valve body can be integral or combined.

The ball valve has the following characteristics:

1. The fluid resistance is small and its drag coefficient is equal to that of the pipe section of the same length.

2. Simple structure, small size and light weight.

3. Tight and reliable. The sealing surface material of the ball valve is widely made of plastic with good sealing. And the valve has been widely used in vacuum system.

4. Convenient operation, quick opening and closing, only 90 rotation from full opening to closing, which is convenient for remote control.

5. Easy Maintenance. The ball valve structure is simple, the sealing ring is generally movable, and disassembly and replacement are more convenient.

6. When the valve is fully open or closed, the sealing surfaces of the ball and valve seat are isolated from the medium, and when the medium passes, it will not cause erosion to the sealing surface.

7. Wide range of applications. The diameter of the valve ranges from several millimeters to several meters and the valve can be applied from high vacuum to high pressure.

The three-piece stainless steel ball valve is a new type of ball valve. It has some advantages: the opening and closing of the valve will not cause friction, the seal is not easy to wear, and the opening and closing torque is small. This can reduce the specifications of the actuator. With the multi-turn electric actuator, the medium can be adjusted and cut off. The valve is widely used in petroleum, chemical industry, urban water supply & drainage and other working conditions that require strict cut-off.

Specification:

| Stainless steel male threaded 3pcs ball valve with ISO 5211 mounting pad | |

| Material | Carbon Steel: ASTM A216 WCB. Stainless Steel: SS304, SS316, 1.4401, 1.4301, ASTM A351 CF8, ASTM A351 CF8M. |

| Standard | Design: DIN 3202-M3, DIN 3357, EN 12516, ASME B16.34. Testing: API 598, EN 12266. |

| Working Pressure | 1000 PSI, 2000 PSI, 3000 PSI, 200 PSI, 800 PSI. |

| Type | 1PC Ball Valve, 2PCs Ball Valve, 3PCs Ball Valve, 3-Way Ball Valve, Swing Check Valve, Y-Type Check Valve, Wafer Check Valve, Vertical Check Valve, Y-Strainer. |

| Connection | NPT, BSP, BSPT, DIN 2999, Flange End. |

| Size | 1/8 Inch to 4 Inch for Threaded End, 1/2 Inch to 12 Inch for Flange End. |

| Application | For Water, Oil and Gas Industry. |

| Certificate | Products: CE, TUV, API. |

The three piece stainless steel ball valve can be closed tightly only by rotating 90 degrees with a small rotating torque. The fully equal body cavity provides a small, straight flow path for the medium. Ball valves are generally considered to be the most suitable for direct closure, but recently, the ball valve is designed to be used for throttling and controlling flow. The main characteristics of ball valves are compact structure, easy operation and maintenance. They are not only applicable to water, solvent, acid and gas and other general work media, but also for media with severe working conditions, such as oxygen, hydrogen peroxide, methane and ethylene. The valve body can be integral or combined.

The ball valve has the following characteristics:

1. The fluid resistance is small and its drag coefficient is equal to that of the pipe section of the same length.

2. Simple structure, small size and light weight.

3. Tight and reliable. The sealing surface material of the ball valve is widely made of plastic with good sealing. And the valve has been widely used in vacuum system.

4. Convenient operation, quick opening and closing, only 90 rotation from full opening to closing, which is convenient for remote control.

5. Easy Maintenance. The ball valve structure is simple, the sealing ring is generally movable, and disassembly and replacement are more convenient.

6. When the valve is fully open or closed, the sealing surfaces of the ball and valve seat are isolated from the medium, and when the medium passes, it will not cause erosion to the sealing surface.

7. Wide range of applications. The diameter of the valve ranges from several millimeters to several meters and the valve can be applied from high vacuum to high pressure.

The three-piece stainless steel ball valve is a new type of ball valve. It has some advantages: the opening and closing of the valve will not cause friction, the seal is not easy to wear, and the opening and closing torque is small. This can reduce the specifications of the actuator. With the multi-turn electric actuator, the medium can be adjusted and cut off. The valve is widely used in petroleum, chemical industry, urban water supply & drainage and other working conditions that require strict cut-off.

Send your message to this supplier

FAQs

While circular knitting machines are generally safe to use, it is important to follow the manufacturer’s instructions and take necessary precautions. This may include wearing protective gloves and avoiding loose clothing near the machine.