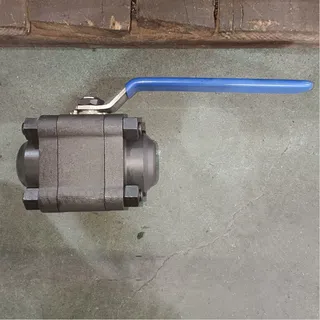

Carbon Steel Ball Valve

Key Specifications / Features

Carbon Steel Ball Valve Maker in China: Carbon Steel Ball Valve, DN50-DN1200, 2 - 48 Inch, CLASS 150 - 2500 LB, API 6D, API 608, ISO 17292, Full or Reduced Bore.

Request a quote

Detail Information

Flanged Ball Valve include Floating Flanged Ball Valve, Trunnion Flanged Ball Valve, Cast Flanged Ball Valve, NSW Ball Valve.

Nominal diameter: DN50-DN1200 (From 2 Inch to 48 Inch).

Pressure: CLASS 150 LB, CLASS 300 LB, CLASS 600 LB, CLASS 900 LB, CLASS 1500 LB, CLASS 2500 LB (PN20, PN50, PN100, PN150, PN250, PN420).

Body Materials:

Forged: ASTM A105, ASTM A182 F304, ASTM A182 F304L, ASTM A182 F316, ASTM A182 F316L, ASTM A182 F51, ASTM A182 F53, ASTM A350 LF2, ASTM A350 LF3, ASTM A350 LF5, Monel, Inconel, Hastelloy.

Casting: ASTM A216 WCB, ASTM A351 CF3, ASTM A351 CF8, ASTM A351 CF3M, ASTM A351 CF8M, ASTM A995 4A, ASTM A995 5A, ASTM A352 LCB, ASTM A352 LCC, ASTM A352 LC2.

Operate: Manual, Worm gear, Pneumatic, Electric-Motorized.

Applicable Temperature: ≤120℃ (PTFE), ≤80℃ (NYLON), ≤ 250℃ (PEEK), ≤ 250℃ (PPL).

Medium: Water, Steam Oil, Gas, Liquefied Gas, Natural Gas, Nitric Acid, Acetic Acid, Strong Oxidizer, Urea, etc.

Application Standards:

Design and Manufacture:API 6D, API 608, ISO 17292.

Face to Face: ASME B16.10, API 6D.

End Connection: ASME B16.5, ASME B 16.47, ASME B16.25.

Test and Inspection: API 598, API 6D.

Fire Safety: API 6FA, API 607.

NACE MR-0175, NACE MR-0103, ISO 15848.

End Connection: Flange (RF, FF, RFJ).

Design 1: Full Bore, Reduced Bore.

Design 2: Side Entry, Top Entry.

Design 3: Double Block & Bleed (DBB), Double Isolation & Bleed (DIB).

Structure Features: Fireproof Structure Design, Reliable Sealing of Valve Stem, Anti-static Structure, Lock And Misoperation Prevention, Double Block And Bleed (DBB), Low Operating Torque, Emergency Sealing Device, Sealant Injection Device, Reliable Seat Sealing Structure, Single Sealing (Automatic Pressure Relief In Middle Cavity Of Valve), Double Sealing (Double Piston), Safety Relief Device, Secial Structure of Automatic Pressure Relief Towards Upper Stream, Blow out Proof Stem, Corrosion Resistance And Sulfide Stress Resistance, Extension Stem.

Application: Water Treatment Plant, Drilling Rigs, Paper Industry, Gas Plant, Sugar Industry, Cooling Water Circulation, Breweries, Heating & Air Conditioning, Chemical Industry, Pneumatic Conveyors, Waste Effluent Treatment Plant, Compressed Air.

Nominal diameter: DN50-DN1200 (From 2 Inch to 48 Inch).

Pressure: CLASS 150 LB, CLASS 300 LB, CLASS 600 LB, CLASS 900 LB, CLASS 1500 LB, CLASS 2500 LB (PN20, PN50, PN100, PN150, PN250, PN420).

Body Materials:

Forged: ASTM A105, ASTM A182 F304, ASTM A182 F304L, ASTM A182 F316, ASTM A182 F316L, ASTM A182 F51, ASTM A182 F53, ASTM A350 LF2, ASTM A350 LF3, ASTM A350 LF5, Monel, Inconel, Hastelloy.

Casting: ASTM A216 WCB, ASTM A351 CF3, ASTM A351 CF8, ASTM A351 CF3M, ASTM A351 CF8M, ASTM A995 4A, ASTM A995 5A, ASTM A352 LCB, ASTM A352 LCC, ASTM A352 LC2.

Operate: Manual, Worm gear, Pneumatic, Electric-Motorized.

Applicable Temperature: ≤120℃ (PTFE), ≤80℃ (NYLON), ≤ 250℃ (PEEK), ≤ 250℃ (PPL).

Medium: Water, Steam Oil, Gas, Liquefied Gas, Natural Gas, Nitric Acid, Acetic Acid, Strong Oxidizer, Urea, etc.

Application Standards:

Design and Manufacture:API 6D, API 608, ISO 17292.

Face to Face: ASME B16.10, API 6D.

End Connection: ASME B16.5, ASME B 16.47, ASME B16.25.

Test and Inspection: API 598, API 6D.

Fire Safety: API 6FA, API 607.

NACE MR-0175, NACE MR-0103, ISO 15848.

End Connection: Flange (RF, FF, RFJ).

Design 1: Full Bore, Reduced Bore.

Design 2: Side Entry, Top Entry.

Design 3: Double Block & Bleed (DBB), Double Isolation & Bleed (DIB).

Structure Features: Fireproof Structure Design, Reliable Sealing of Valve Stem, Anti-static Structure, Lock And Misoperation Prevention, Double Block And Bleed (DBB), Low Operating Torque, Emergency Sealing Device, Sealant Injection Device, Reliable Seat Sealing Structure, Single Sealing (Automatic Pressure Relief In Middle Cavity Of Valve), Double Sealing (Double Piston), Safety Relief Device, Secial Structure of Automatic Pressure Relief Towards Upper Stream, Blow out Proof Stem, Corrosion Resistance And Sulfide Stress Resistance, Extension Stem.

Application: Water Treatment Plant, Drilling Rigs, Paper Industry, Gas Plant, Sugar Industry, Cooling Water Circulation, Breweries, Heating & Air Conditioning, Chemical Industry, Pneumatic Conveyors, Waste Effluent Treatment Plant, Compressed Air.