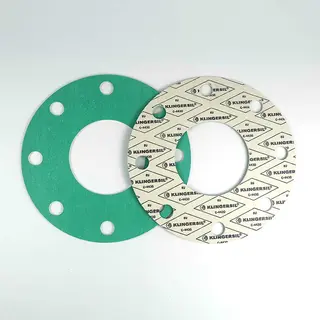

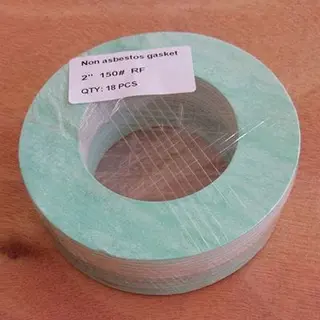

Non-Asbestos Gasket Sheet, Flexible Graphite Filled, Custom

Key Specifications / Features

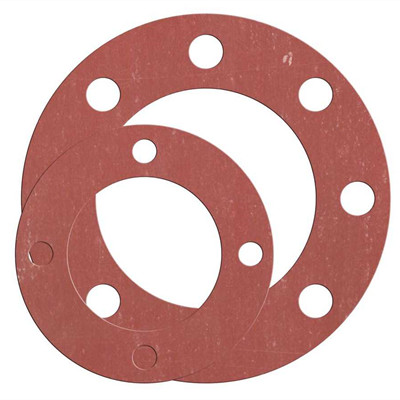

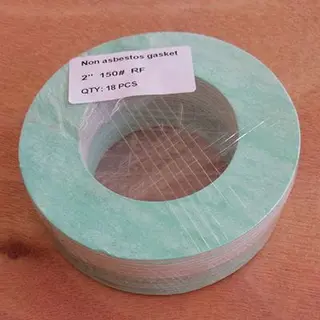

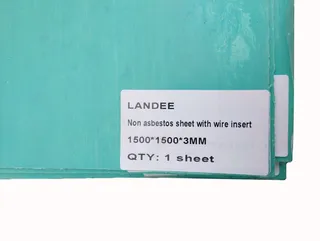

The Non-Asbestos Gasket Sheet Plant produces durable sheets made with flexible graphite filler and non-asbestos fibers, with optional steel wire reinforcement. Engineered for safety and performance, these sheets are ideal for manufacturing various gaskets used in high-temperature and high-pressure industrial environments.

Detail Information

Product Name: Flexible Graphite Filler Non-Asbestos Gasket Sheet

Materials:

Flexible Graphite

Non-Asbestos Fibers

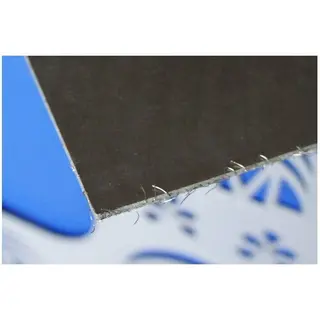

Optional Steel Wire Reinforcement

Structure:

Made from a blend of non-asbestos fibers, synthetic fibers, rubber (latex), graphite, and other additives.

The sheet is formed through pressing and vulcanization.

Steel wire reinforcement can be added to enhance mechanical strength.

Applications:

Suitable for manufacturing various types of gaskets

Ideal for sealing connections in piping and equipment across a wide range of fluid media

Send your message to this supplier

FAQs

What is a Non-Rising Stem Gate Valve?

A valve where the stem does not move vertically but rotates internally to raise or lower the gate. This design is ideal for installations with limited vertical space.

How Does a Non-Rising Stem Gate Valve Work?

The handwheel turns the stem, which in turn moves the gate up or down inside the valve body without changing the external height of the stem.

How Does a Rising Stem Gate Valve Work?

The handwheel lifts the stem and gate together, providing a visual indication of whether the valve is open or closed.

Which Valve Should I Choose?

Use a rising stem valve for above-ground applications where visibility and ease of maintenance are important.

Use a non-rising stem valve for underground or space-limited installations.

Conclusion

The choice between rising stem and non-rising stem gate valves depends on your specific application needs. For clear valve status indication and easy maintenance, go with a rising stem valve. For compact installations, a non-rising stem valve is the better option.