- Products

- Industrial Parts

- Metallurgy, Chemicals, Rubber & Plastics

- Hardware

- Bags, Shoes & Accessories

- Packaging, Advertising & Office

- Electronics

- Home, Lights & Construction

- Apparel,Textiles & Accessories

- Machinery

- Agriculture & Food

- Tools

- Electrical Equipment, Components & Telecoms

- Auto & Transportation

- Gifts, Sports & Toys

- Health & Beauty

- Measurement & Analysis Instruments

- Suppliers

- News

- For Sale

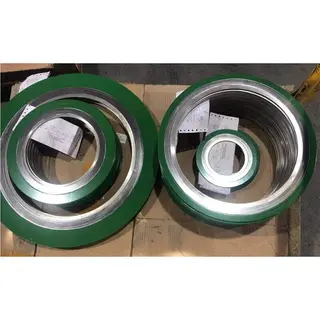

Custom Insulating Flanges, DN50-DN1200, PN6-PN25, Type I/II

Key Specifications / Features

The Customized Insulating Flanges Factory specializes in manufacturing Type I and II insulating flanges, designed for applications in natural gas, city gas, LPG, and other similar industries. These flanges are available in a broad range of sizes from DN50 to DN1200 (2 to 48 inches) and pressure ratings from PN6 to PN25 (0.6 to 2.5 MPa). Engineered to meet high standards of safety and reliability, they effectively prevent electrical conductivity and reduce corrosion risks.

Detail Information

Insulating Flanges are primarily used in gas transmission pipelines, gas regulators, gauges, storage facilities, and other similar applications.

Product Name: Insulating Flange

Sizes: DN50-DN1200 (2-48 Inch)

Pressure range: PN6, PN10, PN16, PN25, 0.6 MPa, 1.0 MPa, 1.6 MPa, 2.5 MPa

Medium temperature: -10°C to +60°C

Ambient temperature: -20°C to +60°C

Insulating resistance: ≥ 500 KΩ

Breakdown voltage: ≥ 3 kV

Applications: Suitable for natural gas, city gas, LPG, and light oil

Classification:

Insulating Flanges can be categorized into two types based on their insulating sealing parts:

Specific-pressure sealed insulating flanges (I-type insulating flanges)

Self-tightening seal insulating flanges (II-type insulating flanges)

Scope of Application: I-type insulating flanges: Nominal pressure (PN) ≤ 2.5 MPa

Features

Provides electrical insulation to prevent electro-corrosion of pipes.

Durable and reliable performance at designed temperature and pressure for pipeline mediums, with sufficient strength and good air-tightness.

Rational structure, easy to assemble, disassemble, and replace.

Send your message to this supplier

FAQs

Similar Products

Related Searches

Products you might also like

Source: https://www.landeepipefitting.com/custom-insulating-flanges-dn50-dn1200-pn6-pn25-type-i-ii.html

Copyright © 2015-2026 China Manufacturers, CNMFRS.COM, All rights reserved.

谷歌优化(Google SEO)