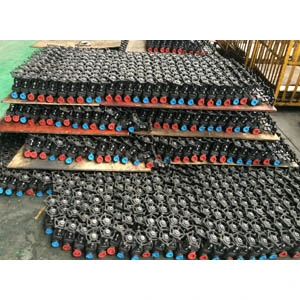

Reduced Bore Top Entry Ball Valve, API 6D, A216 WCB, 10*8 IN

Key Specifications / Features

Detail Information

Product Name: Reduced Bore Top Entry Ball Valve

Design Standard: API 6D

Body Material: ASTM A216 WCB

Size: 10 x 8 Inch, DN250*DN200

Pressure: Class 1500 LB, PN250

End Connection: RTJ Flanged

Operation: Gearbox

Top Entry Trunnion Ball Valves are the perfect solution for both offshore and onshore systems. These valves are designed with convenience of operation and maintenance in mind, simplifying in-line disassembly for trim inspection or internal repairs, even in restrictive spaces. They offer excellent corrosion resistance and superior sealing performance at both high and low pressures. Manufactured in a single forged or cast piece, these valves are configured with two independent seats for bi-directional sealing. They are produced in accordance with customer-specific requirements and international standards.

Technical Specifications

» Size Range: NPS 2-60 Inch (DN50-DN1500)

» Design Pressure: Class 150-2500 LB (PN10-PN420)

» Materials: Cast Carbon Steel, Stainless Steel, Duplex, or Other Special Alloys (ASTM A216 WCB, WCC, A352 LCB, LCC, A351 CF8, CF8M, CF3, CF3M)

» Ends Connections: Flanged RF, RTJ, Welded BW

» Operation: Handle, Worm Gear, Electric, Pneumatic

» Temperature Range: -46°C to 200°C

» Medium: Water, Gas, Oil

» Standards:

Design and Manufacture: API 6D, GB/T 19672, GB/T 12237

Face-to-Face Dimensions: ASME B16.10, GB/T 12221

Flanged Connections: ASME B16.5, ASME B16.47, GB/T 9113, JB/T 79

Test and Inspection: API 598, API 6D, GB/T 13927

Butt Welded End: ASME B16.25

Fire Safety Standards: API 607, API 6A

Product Features

» One-Piece Flange Top Entry Trunnion Design

» Double Block and Bleed (DBB/DIB-1/DIB-2) Design Diversity

» One-Piece Ball and Stem for Precise Positioning

» Anti-Blowout One-Piece Ball/Stem Design

» O-Rings Plus Fire-Safe Packing to Prevent Leakage

» Corrosion-Resistant Low-Friction Bearings

» Wave Springs for Upstream and Downstream Sealing

» Stainless Steel Sealant Injection Fittings for Emergency Stem or Seat Sealing

» Inline Repairable Due to Reasonable Seat Retainer Design

» Minimized Torque Required to Open and Close Valve

» Anti-Static Grounding Between Ball, Stem, and Body

» Integral Top Works Direct Mounting Pad

» Optional Locking Device or Stem Extension

» Emergency Rescue and Valve Lubrication

» Low Torque Value