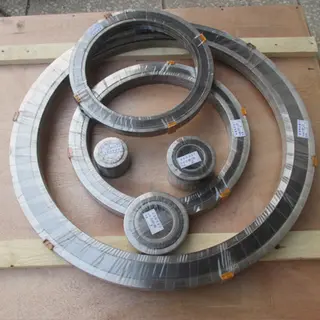

Metal Graphite Spiral Wound Gasket, 1/2-60 IN, THK 0.4–6 mm

Key Specifications / Features

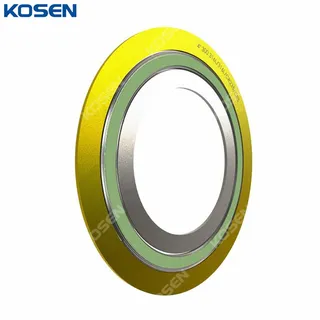

The Metal Graphite Spiral Wound Gasket is made from a combination of metal and filler materials. Available in sizes ranging from 1/2 to 60 inches (DN15–DN1500) and thicknesses from 0.4mm to 6.0mm, these gaskets conform to international standards such as ASME, BS, JIS, EN (DIN), and others. Known for their excellent sealing properties and resistance to high temperatures and pressures, these gaskets are ideal for use in pipes, pumps, valves, flanges and other critical components .

Detail Information

Product Name: Metal Graphite Spiral Wound Gasket

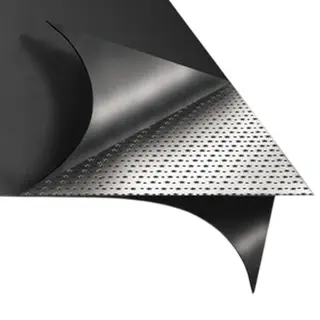

Material: Metal + Filler Material

Size: 1/2-60 Inch (DN15–DN1500)

Thickness: 0.4mm–6.0mm

Standards: ASME, BS, JIS, EN (DIN), and others

Stamping: as per Customer's Request

Application: Pipes, Flanges, Valves, Pumps

The metal graphite spiral wound gasket is designed to prevent the leakage of air, gas, water, or other fluids by filling gaps between two surfaces. These surfaces, which have channels for fluid movement, may not be perfectly flush or smooth, leading to potential leakage paths. The gasket is placed between the surfaces, where it compresses to seal the gaps effectively, ensuring no leakage. The ability of the gasket to withstand degradation and damage plays a critical role in its performance and longevity.

Product Features

Key selection factors for metal gaskets include material, type, and intended use. Buyers should consider the following when purchasing:

» The force exerted by the two surfaces on the gasket

» Surface unevenness, which influences gasket thickness

» Exposure to liquids and environmental pollutants

» The compressibility of the gasket material

Knowing the application environment helps in choosing the appropriate gasket material that can resist water, acidic or alkaline chemicals, oxidation, and other factors. Additionally, selecting the right thickness, service life, and ductility ensures optimal gasket performance.