Lugged Knife Gate Valves, GGG40, 10 IN, CL150, Bidirectional

Key Specifications / Features

Detail Information

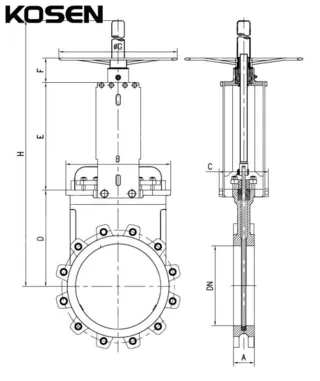

Product Name: Lugged Knife Gate Valves

Type: Bidirectional Knife Gate Valve

Body Material: GGG40, Ductile Cast Iron

Size: 10 Inch, DN250

Pressure: Class 150 LB, PN16

End Connection: Lug

Operation: Manual

The Cast Iron Bidirectional Knife Valve is a unidirectional wafer-style gate valve designed for on-off operation in industrial pipelines. Its unique body and seat structure effectively prevent clogging during shutoff, even when handling flows with fine particles. The beveled knife edge allows the gate to easily cut through thick media, ensuring efficient operation. Depending on the working conditions, this valve is available in both non-rising stem and rising stem configurations to suit various applications.

Technical Specifications

» Nominal Diameter: NPS 2–16 Inch (DN50–DN400)

» Design Pressure: PN10, PN16, Class 150 LB

» Temperature Range: -29°C to 120°C

» Max Working Pressure:

DN50–DN250: 10 bar

DN300–DN450: 7 bar

DN500–DN600: 4 bar

» Body Material: GGG40, ASTM A351 CF8, CF8M, Special Alloys, etc.

» Disc Material: Stainless Steel, Chrome Plated, Special Alloys, etc.

» Seat Material: EPDM (120°C), NBR (80°C)

» Flange Standard: GB/T 9113.1, JB/T 79.1, HG 20592, ASME B16.5, EN 1092-1

» Face-to-Face: MSS SP-81

» Operation: Manual, Pneumatic, Electric, Hydraulic

Product Features

» Integral Body Design: Simplifies assembly while ensuring zero shell leakage.

» Full Port Design: Reduces pressure drop and maximizes flow capacity for enhanced performance.

» Cavity-Free Bore: Prevents particle accumulation within the valve body, ensuring smooth operation.

» Beveled Knife Edge: Delivers strong cutting force for tight, reliable sealing.

» Customizable Gate Thickness: Can be increased to meet higher pressure requirements.

» Polished Gate Surface: Both sides of the gate are polished for optimal sealing and reduced jamming.

» U-Shaped Elastomer Seat: Provides a peripheral seal along the gate edge, ensuring a tight seal in both flow directions.

» Stem Cover: Protects the stem, extending its service life.

» Dual Thrust Bearings: Minimize operational torque for smoother valve actuation.

» Grease Nipple: Facilitates bearing lubrication to maintain long-lasting performance.