Inverted Bucket Steam Trap, ISO 6552, A216 WCB, DN25, PN16

Key Specifications / Features

The Inverted Bucket Steam Trap, manufactured to ISO 6552/EN 26704 standards, features a carbon steel ASTM A216 WCB body for durability and corrosion resistance. Sized at 1 inch (DN25), it supports PN16 and Class 150 LB pressure ratings with threaded ends for secure connection. Designed for efficient condensate removal and steam flow control, this trap ensures reliable operation in steam systems, minimizing energy loss and enhancing system efficiency.

Detail Information

Product Name: Inverted Bucket Steam Trap, 881 Thread

Design Standard: ISO 6552, EN 26704

Body Material: ASTM A216 WCB

Size: DN25, 1 Inch

Pressure: PN16, Class 150 LB

End Connection: Threaded

The inverted bucket type steam trap is a mechanical steam trap known for its exceptional performance across low, medium, and high-pressure applications. It features stainless steel internal components and a heat-treatable steel base, ensuring a robust structure that resists abrasion and corrosion, offering long-lasting durability.

This steam trap is highly recommended for condensate recovery systems due to its steam-saving capability, high thermal efficiency, and anti-back pressure characteristics. Additionally, it can be equipped with a check valve to save piping space. The inverted bucket type steam trap is designed to deliver reliable performance and efficiency, making it an ideal choice for various industrial applications.

Technical Specifications

Normal Size Range: 1/2 Inch - 1 Inch (DN15-DN25)

Normal Pressure Rating: PN16, PN25 , Class 150 LB

Material: ASTM A216 WCB, A351 CF8, CF8M, CF3, CF3M

Maximum Allowable Pressure (PMA): 40 Barg

Maximum Allowable Temperature (TMA): 300°C

Maximum Differential Pressure (ΔPMX): 20 Bar

Medium: Steam condensate

Standards

Design and Manufacture: ISO 6552; EN 26704

Face to Face (End to End): EN 26554

Flanged Connection: GB/T 9113

Test and Inspection: EN 26948

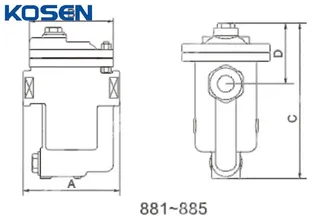

Main Dimensions

|

Size |

A |

B |

C |

D |

Weight |

|

DN15 |

127 |

103 |

180 |

102 |

2.7 |

|

DN20 |

127 |

103 |

180 |

102 |

2.7 |

|

DN25 |

127 |

103 |

180 |

102 |

2.7 |