Double Acting Hydraulic Actuator, Max 400,000 Nm, 5-31.5 MPa

Key Specifications / Features

Detail Information

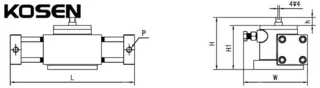

Product Name: Double Acting Hydraulic Actuator

Product Type: Double Acting / Single Acting

Output Torque: Up to 400,000 Nm

Hydraulic Pressure:

Low Pressure: 5 MPa

Medium Pressure: 16 MPa

High Pressure: 31.5 MPa

Hydraulic Medium: Hydraulic oil or other flame-resistant hydraulic fluid

Ambient Temperature: -30°C to +100°C (Special temperature ranges available upon request)

The hydraulic actuator is a device that uses hydraulic power to control the opening and closing of valves. Based on operation, hydraulic actuators can be categorized into three main types:

» Rotary Hydraulic Actuators: Primarily used for controlling butterfly valves, ball valves, and other valves with a 0°-90° rotating motion.

» Linear Hydraulic Actuators: Used for controlling globe valves, gate valves, and other valves that require a straight stroke motion.

» Multiple Rotary (Screw-Down) Hydraulic Actuators: Used when mechanical self-locking conditions are necessary for the valve operation.

Additionally, hydraulic actuators can be classified based on their mode of action:

» Double-Acting Hydraulic Actuators: These actuators use hydraulic oil for both opening and closing the valve.

» Spring Return Hydraulic Actuators: In these actuators, hydraulic oil is used to drive the opening or closing of the valve, while mechanical reset mechanisms are used for the opposite movement. The spring return hydraulic actuator provides fault protection, automatically closing or opening the valve when power, control signals, or pressure is lost.

Flowtecal hydraulic actuators are also available in two variants based on their work environment:

» Immersion-Type Hydraulic Actuators: These actuators are designed to be submerged in seawater at depths of 30-60 meters, providing long-term corrosion resistance. They are commonly used in shipbuilding, marine engineering, and tidal power applications.

» Dry-Type Hydraulic Actuators: Designed for dry environments with standard operational conditions.

Design Features

» Torque Structure: Small and medium-torque hydraulic actuators utilize a pinion and rack structure, while high-torque actuators use a scotch yoke type mechanism. The F4 series actuators are compact, durable, and offer high efficiency across a wide torque range.

» Lightweight Design: The high-pressure power of the hydraulic system allows for a lighter actuator compared to pneumatic or electric alternatives.

» Integrated Hydraulic Power Source: The oil tank, motor, hydraulic pump, and accumulator are integrated into a stable and reliable hydraulic power source, tailored to meet user needs. This solution is ideal for both general use and applications with lower-reliability power supply requirements.

» Hydraulic Control Systems: The actuator features pressure, flow, and directional control valves, along with electric control components, to provide a variety of hydraulic control systems. These systems meet diverse functional, protection, and explosion-proof requirements.

» High Positioning Accuracy: The incompressibility of hydraulic fluid and zero-leakage system maintain high positioning accuracy and reliability, making the electro-hydraulic actuator suitable for precise control.

» Emergency Self-Protection: The actuator offers emergency self-protection functions, including automatic opening and closing when the valve loses power.

» Rapid Valve Operation: Hydraulic actuators enable fast valve opening and closing.

» Flammable Hydraulic Liquids: In high-temperature and flammable environments, special sealing rings allow the use of flammable hydraulic fluids (e.g., EH oil).

» High-Accuracy Control: Proportional and servo valves enable both high-accuracy position control and speed control, enhancing the actuator’s ability to regulate valve movement precisely.

.jpg)