DBB Trunnion Ball Valve, BS 5351, ASTM A105N, 8 Inch, CL150

Key Specifications / Features

The ASTM A105N DBB Ball Valve is a high-performance, trunnion-mounted valve designed for secure and reliable flow control. Manufactured to API 6D and BS 5351 standards, it features a carbon steel body, double block and bleed (DBB) design, and raised face (RF) ends. With an 8-inch (DN200) size and pressure ratings of Class 150 LB / PN20, this valve ensures tight shutoff and operational safety, making it ideal for critical oil, gas, and industrial pipeline applications.

Detail Information

Product Name: DBB Trunnion Mounted Ball Valve, Double Block & Bleed

Design Standard: API 6D, BS 5351

Body Material: ASTM A105N

Size: 8 Inch, DN200

Pressure: Class 150 LB, PN20

End Connection: RF

Operation: Gearbox

Medium: Water, Oil, Gas, etc

Temperature Range: -46°C to 350°C

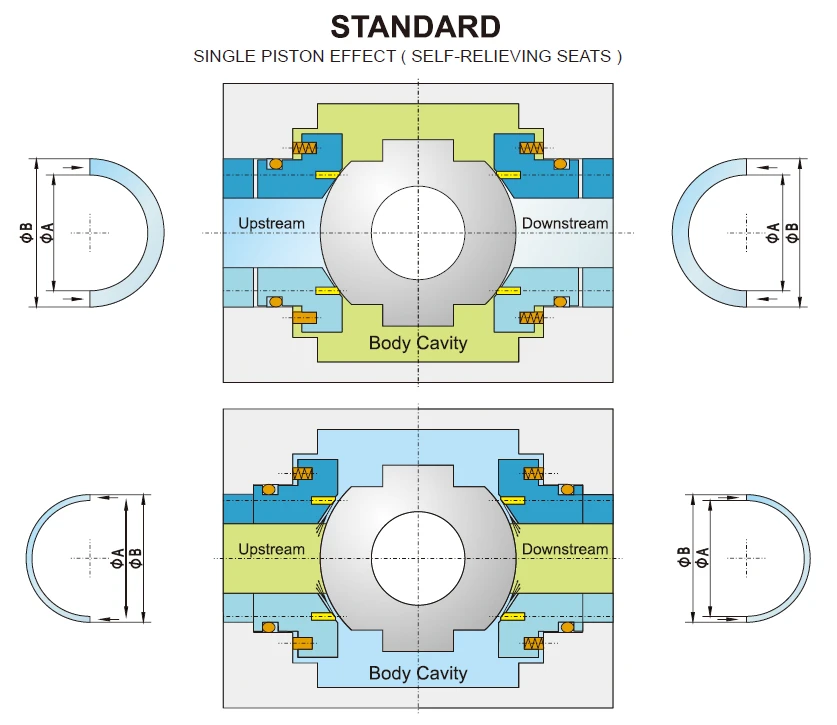

Double Block and Bleed (DBB) Valves provide double isolation functionality with two obturators inserted into a single body. These valves offer a bleed function through a bleed/vent system located between the obturators (body port and ball, gate, or needle valve). Designed from a trunnion ball valve structure, DBB valves come in several different constructions. DBB ball valves allow for a pipe section to be shut down from both sides, ensuring safety by preventing accidental leaks, making them ideal for the oil and gas industry. The design not only enhances safety but also reduces the need for additional valves, saving space and reducing costs.

Technical Specification

» Product: DBB Trunnion Ball Valve

» Size Range: NPS 1/2-24 Inch (DN15-DN600)

» Temperature Range: -46°C to 350°C

» Design Pressure: Class 150-2500 LB (PN10-PN420)

» Materials: Forged Carbon Steel, Stainless Steel, Duplex Steel, or Other Special Materials

» Trim Materials: 13%Cr, SS 304, SS 304L, SS 316, SS 316L, and Other Special Materials

» Ends Connections: RF and FTJ Flanged

» Operation: Handle, Worm Gear, Electric, Pneumatic

» Design and Manufacture: API 6D, BS 5351, ASME B16.34

» Face to Face (End to End): As per Manufacturer's Standard

» Flanged Connection: ASME B16.5

» Test and Inspection: EEMUA 182, API 598

» Threaded Ends: ASME B1.20.1

» Fire Safety: API607, API6A

Product Features

» Integrated DBB body design with a dual-type configuration

» Side Entry Forged Steel Valves

» Top-entry design available upon request

» Low pressure loss through the valve

» Low actuation torque

» Full bore or reduced bore options

» Anti-corrosion materials per NACE MR 0175 standards

» Metal-sealed seat pocket area overlay or complete cladding on wetted surfaces (welded overlays in Inconel 625, Stainless Steel 316, etc., or Electroless Nickel Plating)

Send your message to this supplier

FAQs

DBB (Double Block and Bleed): Two single piston-effect seats.

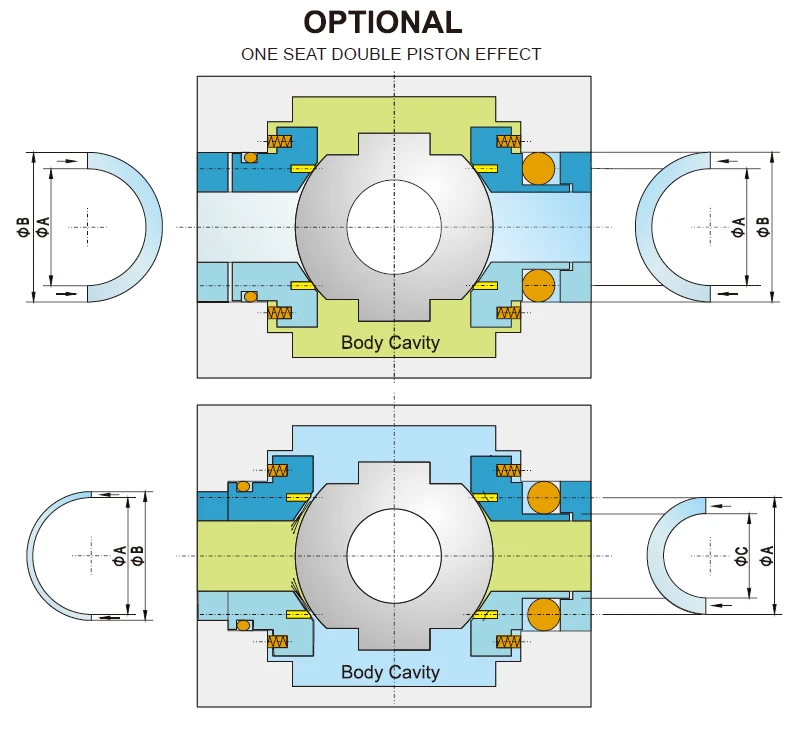

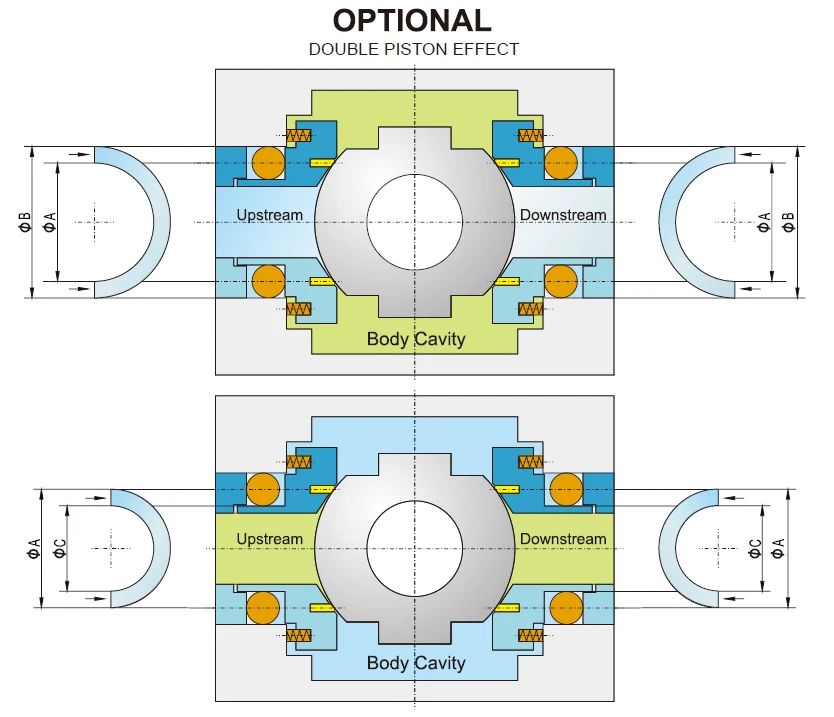

DIB-I (Double Isolation and Bleed Type I): Two double piston-effect seats.

DIB-II (Double Isolation and Bleed Type II): One double piston-effect seat and one single piston-effect seat.