ASTM A890 5A Axial Check Valve, API 6D, 6 Inch, 300 LB, RF

Key Specifications / Features

Detail Information

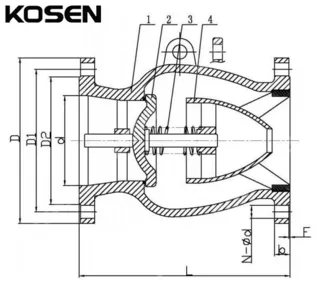

Product Name: Axial Flow Non-slam Check Valve

Design Standard: API 6D, ASME B16.34

Body Material: ASTM A890 5A

Size: 6 Inch, DN150

Pressure: Class 300 LB, PN50

End Connection: RF

The Axial Flow Check Valve is designed to offer the general function of a check valve with enhanced advantages such as reduced noise and lower impact, thanks to its spring-assisted operation. Its axial flow structure minimizes fluid resistance, provides excellent flow capacity, and features a compact size. These characteristics make it an ideal choice for use on the pump outlet in pipeline systems transporting oil, gas, water, and other fluids. This valve ensures reliable non-return performance in various applications, particularly where backflow prevention is critical.

Technical Specifications

» Nominal Diameter: NPS 2-36 Inch (DN50-DN900)

» Design Pressure: Class 150-2500 LB (PN10-PN420)

» Materials: ASTM A216 WCB, WCC, A217 WC6, WC9, C5, C12A, A352 LCB, LCC, A351 CF8, CF8M, CF3, CF3M, CF8C

» Design and Manufacture: GB/T 21387, API 6D, ASME B16.34

» Face to Face (End to End): GB/T 12221, ANSI B16.10, API 6D

» Flanged Connection: GB/T 9113, ASME B16.5

» Test and Inspection: GB/T 26480, API 598

» End Connections: Flanged (FF, RF, RTJ) to international standards

» Temperature Range: -29°C to 595°C

» Medium: Water, gas, oil, etc.

Product Features

» One-Piece Body: Lightweight, strong, and easy to maintain.

» Spring-Assisted Closure: The thrust force of the spring ensures the valve stays closed, even without medium flow.

» Versatile Installation: Can be installed in any direction, with the disc perfectly sealing against the seat.

» Axial Flow Structure: Minimizes pressure loss, stabilizes medium flow, and prevents cavitation erosion. The spring and sub-pressure allow the disc to return to the sealing position without direct impact from the medium.

» Low Noise: Features a low-noise design for quieter operation.

» Enhanced Sealing: Special surface treatment of the disc carrier and pin prevents sticking and ensures consistent, centered disc positioning for reliable, lasting sealing.

» Reliable Closing Mechanism: The spring’s thrust force is slightly higher than the disc’s gravity and friction, ensuring the disc returns to its sealing position, even under low pressure, and protecting pump operation.