ASTM A351 CF8 Cryogenic Globe Valve, BS 1873, DN65, PN20, BW

Key Specifications / Features

The ASTM A351 CF8 Cryogenic Globe Valve Supplier offers high-performance cryogenic globe valves designed to meet the BS 1873 standard. These valves feature a cast stainless steel body made from CF8 material, ensuring excellent corrosion resistance and durability in low-temperature applications. With a DN65 (2-1/2 inch) size and a pressure rating of PN20, they are suitable for handling cryogenic fluids such as LNG (liquefied natural gas), LO2 (liquid oxygen), LN2 (liquid nitrogen), LAr (liquid argon), and CO2 (carbon dioxide). The valves have butt-welded ends for seamless integration into cryogenic systems.

Detail Information

Product Name: ASTM A351 CF8 Cryogenic Globe Valve

Design Standard: BS 1873

Body Material: ASTM A351 CF8

Size: DN65, 2-1/2 Inch

Pressure: PN20, Class 150 LB

End Connection: Butt Weld

Operation: Manual

Medium: LNG, LO2, LN2, LAr, CO2

Temperature Range: -196°C to 80°C

The cryogenic globe valve is specifically designed to perform reliably under low-temperature and cryogenic conditions. Constructed from durable materials such as stainless steel, carbon steel, and cast steel, it features an extended bonnet that protects the stem packing by distancing it from the cryogenic medium. The length of the bonnet varies depending on the application and user requirements. These valves are commonly used in LNG facilities, ethylene plants, and gas production terminals, and are capable of throttling fluids at temperatures as low as -196°C. We offer a wide range of high-performance cryogenic globe valves tailored to meet diverse industrial needs.

Technical Specification

» Nominal Diameter: DN65–DN100, 2-1/2 Inch – 4 Inch

» Design Pressure: PN20, Class 150 LB

» Material Options: ASTM A351 CF8, CF8M, CF3, CF3M, etc.

» Operating Temperature Range: -196°C to +80°C

» Design & Manufacturing Standard: BS 1873

» Face-to-Face Dimensions: ASME B16.10

» Flange Dimensions: ASME B16.5

» Pressure Testing Standard: API 598

» NACE Compliance: NACE MR0103 / NACE MR0175

» Operator Options: Handwheel

» Connection Type: Butt Weld

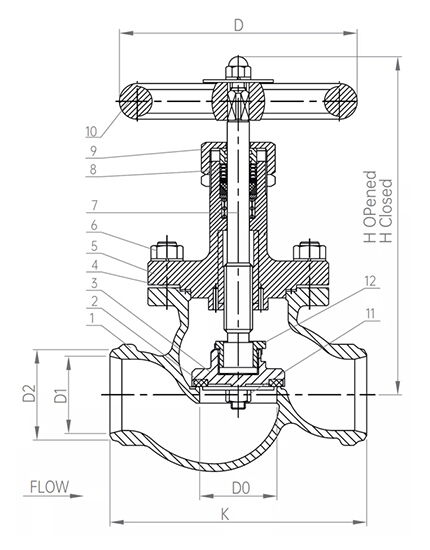

Structural Diagram