ASTM A351 CF8 Butterfly Check Valve, DN200, PN25, 8 Inch, RF

Key Specifications / Features

Detail Information

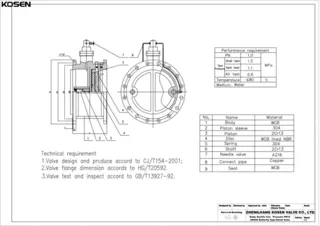

Product Name: Butterfly Type Check Valve

Body Material: ASTM A351 CF8

Size: DN200, 8 Inch

Pressure: PN25, Class 300 LB

End Connection: RF Flanged

Product Range

» Structure: Butterfly Type Check Valve

» Port Size: DN350–DN1200, 14–48 Inch

» Pressure: PN10, PN16, PN25, Class 150-300 LB

» Body Material: Cast iron, ductile iron, carbon steel, stainless steel

» Connection: RF Flange

» Medium: Clear water, sewage, seawater, etc.

» Temperature: -20°C to 80°C

The Butterfly Type Check Valve is designed to prevent backflow and effectively limit destructive water hammer, ensuring the safe operation of drainage pipelines. It is suitable for clean water, sewage, seawater, and similar media but is not recommended for granular media or high-viscosity fluids.

Key features include a novel structure, compact size, light weight, low fluid resistance, reliable sealing, stable operation, wear resistance, and long service life. The valve operates with oil pressure and slow closing, unaffected by the medium, contributing to energy savings. It is widely used in various industries, including urban construction, with positive feedback.

Butterfly Check Valve Working Principle

The Butterfly Type Check Valve consists of a valve body, two semi-circular discs, a return spring, oil cylinder, small cylinder group, and a needle valve (micro control valve). The valve's operation relies on the thrust action of the inlet medium, pushing the discs smoothly.

» When the inlet pressure is higher than the outlet pressure, the medium pushes the discs open.

» The piston in the oil cylinder is pushed, and oil flows through the needle valve into the small cylinders, moving the piston rod out.

» When the inlet pressure drops below the outlet pressure, the spring and medium cause the valve discs to close automatically. However, due to the extended piston rod, the valve discs don’t fully close, leaving around 20% of the area open to allow medium flow, helping to eliminate water hammer.

» The valve disc is divided by the piston, ensuring fast and slow closing to prevent motor reversal and minimize noise.

Butterfly Check Valve Features

» Novel structure, compact, and lightweight

» Reliable sealing and stable operation

» Wear resistance and long service life

» Slow closing to prevent water hammer

» Energy-saving and efficient design

Materials of Main Parts

|

NO |

Part name |

Material |

|

1 |

Body |

Ductile Iron, ASTM A216 WCB |

|

2 |

Piston sleeve |

SS 304 |

|

3 |

Piston |

2Cr13 |

|

4 |

Disc |

ASTM A216 WCB + Lining NBR |

|

5 |

Spring |

SS 304 |

|

6 |

Shaft |

2Cr13 |

|

7 |

Needle Valve |

Assembly |

|

8 |

Connect pipe |

Copper or SS 304 |

|

9 |

Seat |

ASTM A216 WCB |