ASTM A216 WCB Butterfly Valve, API 609, 4 Inch, 150 LB, Lug

Key Specifications / Features

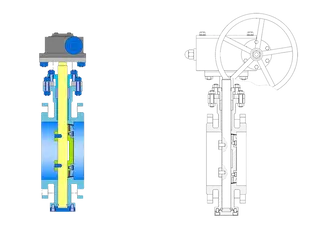

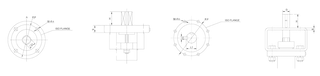

The ASTM A216 WCB Butterfly Valve features a triple eccentric design, adhering to API 609 standards. This valve has a carbon steel body and is available in a 4-inch (DN100) size with a pressure rating of Class 150 LB (PN20). It is equipped with lug ends for secure mounting and includes a wormgear actuator for smooth and reliable operation. This valve is designed for high-performance applications requiring precise flow control and durability.

Detail Information

Product Name: ASTM A216 WCB Triple Eccentric Butterfly Valve

Design Standard: API 609

Body Material: ASTM A216 WCB

Size: 4 Inch, DN100

Pressure: Class 150 LB, PN20

End Connection: Lug

Operation: Wormgear

We offer a comprehensive range of Triple Eccentric Butterfly Valves, available in various pressure classes, body styles, and materials to meet critical process requirements across industries such as hydrocarbon, power, chemicals, and fertilizers. These valves are designed for ASME classes up to 600 LB, with sizes reaching 64 inch (1600 mm) and materials including carbon steel, stainless steel, and alloy steels, suitable for temperatures up to 538°C (1000°F). Higher pressure classes, larger sizes, and specialized materials are available upon request, including options for cryogenic services. The metal-seated design conforms to API 609, ensuring bi-directional sealing with high integrity. Precision manufacturing utilizes 5-axis machining centers and customized welding machines for superior quality and performance.

Technical Specifications

» Size Range: 2-40 Inch (DN50-DN1000) (Larger sizes upon request)

» Pressure Ratings: Class 150-600 LB (PN10-PN100)

» Body Material:

Carbon Steel (ASTM A216 WCB)

Stainless Steel (ASTM A351 CF8/CF8M/CF3/CF3M)

Low Temp Steel (ASTM A352 LCB/LCC)

» Shaft Material: 17-4PH, SS 410, XM-19

» Seat Material: Fully metal seat, SS + Graphite Seat

» Operation: Handle, Worm Gear, Pneumatic, Electric

» Temperature Range:

Metal Seat: -29°C to 425°C

Metal Seat (Cryogenic): -196°C to 121°C

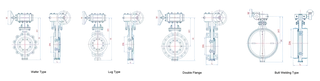

» End Connections: Wafer, Lugged, Double Flanged, Butt Weld, Grooved

» Actuators: Manual, Pneumatic, Electric, Hydraulic, Counterweight, Electro-hydraulic

» Medium: Water, Gas, Oil, etc.

Product Features

» Lockable Lever for secure operation

» Easy Maintenance with site-friendly design

» Automation Ready for seamless integration

» Positive Tight Shut-Off ensuring reliable sealing

» Optional Top Flanges conforming to ISO 5211

» Suitable for Both Gaseous and Liquid Services

» Versatile Material Selection for various medium applications

» Compliance with Standards: ISO 5752, BS 5155, API 609, MSS-SP-68, ASME B16.10, ASME B16.5, DIN 3202

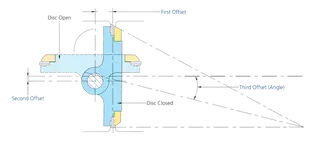

Triple Offset Butterfly Valve

Triple offset metal sealing butterfly valve uses the three eccentric structure with multi-layer metal seal or pure metal sealing ring, different sealing materials are being used according to the different temperature request from end user.The structure of valve sealing ring that was formed after machining for triple eccentric butterfly valve is oblique cone type, the purpose of which is to let the disc open in a subtle angle and seat sealing surface can be completely separated from the sealing surface of disc, thus to reduce the friction of sealing surface during the open and close.

Triple Offset Frictionless Design

- Offset 1: Offset for seat seal and the rotation center of stem.

- Offset 2: Center of pipe and disc.

- Offset 3: Seat sealing angle center line and flow passage center.

- The triple offset of butterfly valve ensures the valve disc is completely separated from seat sealing surface while open in a slightly angle which could reduce the friction of sealing surface during open and close and opening torque as well as prolong the service life of the sealing surface.

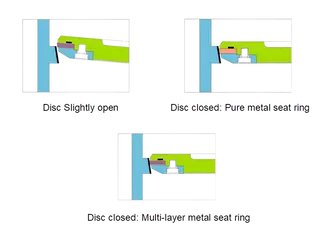

- Our metal sealing butterfly valve adopts multi-layer sealing ring to achieve the valve seal, the multi-layer seal ring is generally made of stainless steel and graphite combination The pure metal sealing can be used for special medium or high temperature.

Seat Structure

- Low Operating Torque: Our butterfly valves combine three offsets. Standard sealing is graphite + metal. Optional PTFE + metal combinations are available for different temperatures and media, using flexible laminated metal and graphite to ensure a tight, uniform seal and reduce operating torque.

- Zero Leakage: Laminated seal rings are self-aligning, allowing the valve to meet zero leakage per API 598.

- Fire-Safe Design: Standard valves are not soft-seated and meet API 607 fire-safe requirements.

- Anti-Blowout Shaft: Double anti-blowout design meets API 609 and ASME B31.1.

- Top Retention: Packing gland follower retains the stem.

- Bottom Retention: T-shaped collar prevents stem blowout.

ISO 5211 Top Mounting

Different End Connections Available: