ASTM A216 WCB Axial Check Valve, ASME B16.34, 24 IN, CL150

Key Specifications / Features

Detail Information

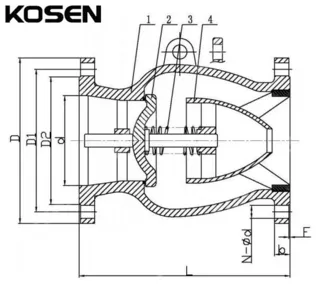

Product Name: ASTM A216 WCB Axial Flow Check Valve, One Piece Body

Design Standard: API 6D, ASME B16.34

Body Material: ASTM A216 WCB

Size: 24 Inch, DN600

Pressure: Class 150 LB, PN20

End Connection: RF Flange

In addition to the standard functionality of a check valve, the axial flow check valve offers advantages such as reduced noise and lower impact, thanks to the integration of a spring. Featuring an axial flow design, this valve has low fluid resistance, high flow capacity, and compact dimensions. These characteristics make it an ideal choice for installation at the outlet of pumps in pipeline systems transporting oil and gas. It is commonly used in pipelines for the transportation of oil, gas, water, and other fluids, especially in applications requiring non-return protection.

Technical Specifications

» Nominal Diameter: NPS 2-36 Inch (DN50-DN900)

» Design Pressure: Class 150-2500 LB (PN10-PN420)

» Materials: ASTM A216 WCB, WCC, A217 WC6, WC9, C5, C12A, A352 LCB, LCC, A351 CF8, CF8M, CF3M, CF8C

» End Connections: Flanged (FF, RF, RTJ) to international standards

» Temperature Range: -29°C to 595°C

» Medium: Water, gas, oil, etc.

Standards and Compliance

» Design and Manufacture: GB/T 21387, API 6D, ASME B16.34

» Face to Face (End to End): GB/T 12221, ANSI B16.10, API 6D

» Flanged Connection: GB/T 9113, ASME B16.5

» Test and Inspection: GB/T 26480, API 598

Product Features

» One-piece Body: Lightweight, strong, and easy to maintain.

» Spring Thrust Force: The spring’s thrust keeps the valve in a closed position even without the medium’s force.

» Versatile Sealing: The valve can be installed in any orientation, with the disc perfectly sealing against the seat, ensuring reliable operation.

» Axial Flow Structure: The accurate flow path minimizes pressure loss, stabilizes medium flow, and prevents cavitation erosion. The disc returns to its sealing position using the spring’s force and the sub-pressure generated by the medium flow, ensuring no direct impact on the disc’s backside. This design results in low noise during operation.

» Smooth Operation: The special design and surface treatment of the disc carrier and pin prevent valve sticking. The valve disc opens and closes evenly, avoiding the common issue where the disc fails to stay centered due to gravity, ensuring lasting, effective sealing.

» Sealing Reliability: In the closed position, the spring’s thrust force slightly exceeds the combined force of the disc’s gravity and the friction between the disc and sealing ring. This allows the disc to return to its sealing position under low pressure, regardless of the installation orientation, protecting the pump during operation.