API 600 Gate Valve, ASTM A216 WCC, 2-1/2 Inch, 1500 LB, BW

Key Specifications / Features

Detail Information

Product Name: API 600 Pressure Seal Gate Valve

Design Standard: API 600, ASME B16.34

Body Material: ASTM A216 WCC

Size: 2-1/2 Inch, DN65

Pressure: Class 1500 LB, PN250

End Connection: BW

Operation: Bare Stem

Pressure Seal Gate Valves are engineered in compliance with API 600 and ASME B16.34 standards, offering reliable performance in high-temperature and high-pressure applications, commonly found in fossil fuel power plants. The pressure seal design provides superior sealing at the bonnet joint, making these valves more compact, rigid, and cost-effective in maintenance compared to traditional bolted bonnet joint valves. They are specifically designed for service in demanding conditions, ensuring long-lasting durability and reduced operational costs.

Technical Specification

» Nominal Diameter: NPS 2-24 Inch (DN50-DN600)

» Design Pressure: Class 600-2500 LB (PN100-PN420)

» Material: Cast or Forged Carbon Steel, Stainless Steel, Duplex Steel, Special Materials

» Trim Materials Available: 13% Cr, ASTM A182 F11, F22, SS 304

» End Connections: BW, RF, RTJ

» Operation: Hand wheel, bevel gear, electric, pneumatic

» Temperature Range: -29°C to 595°C

» Medium: Water, gas, oil, etc.

» Design and Manufacture: ANSI B16.34, API 600, API 6D, BS 1414

» Face to Face (End to End): ANSI B16.10, API 6D

» Flanged Connection: ANSI B16.5

» Butt Welded End: ANSI B16.25

» Test and Inspection: API 598, API 6D

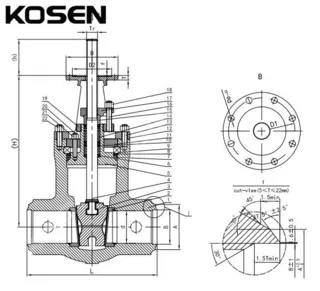

» Key Components

Back-Up Ring: Absorbs thrust applied by internal pressure

Thrust Ring: Protects the soft metallic gasket from deformation

Gasket: Unique angular design ensures superior sealing

Optional Bypass System

Live Loading Packing & O-ring Seal

Product Features

» Wide Application: The design and material selections make KOSEN Pressure Seal Gate Valves ideal for steam-generation stations, industrial chemical plants, and thermal power plants.

» Material Options: Available in Cast Steel and Forged Steel body designs, offering versatility to meet varying application requirements.

» Reliable and Simple Design: These gate valves are characterized by their simple structure, reliability, and excellent sealing capabilities.

» Flexible Deformation: The gate valve is designed to allow slight flexible deformation, compensating for deviations in the sealing face angle that may occur during processing. This feature enhances overall performance and sealing reliability.

» Durable Seal Surface: The seat and gate disc seal surfaces are overlaid with iron-base alloy, Co-base alloy, or carbide alloy, ensuring long-lasting durability and superior sealing under high-pressure conditions.