- Products

- Industrial Parts

- Metallurgy, Chemicals, Rubber & Plastics

- Hardware

- Bags, Shoes & Accessories

- Packaging, Advertising & Office

- Electronics

- Home, Lights & Construction

- Apparel,Textiles & Accessories

- Machinery

- Agriculture & Food

- Tools

- Electrical Equipment, Components & Telecoms

- Auto & Transportation

- Gifts, Sports & Toys

- Health & Beauty

- Measurement & Analysis Instruments

- Suppliers

- News

- For Sale

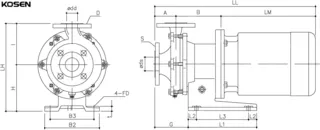

750W Magnetic Drive Pump, 3 Phase, Max 260 L/min, 18M Head

Key Specifications / Features

The 750W Magnetic Drive Pump features a 1.5-inch thread interface and a 36 mm tube, designed for efficient fluid handling in various industrial applications. With a maximum capacity of 260 L/min and a maximum water head of 18 meters, this pump offers reliable performance for medium to high-flow systems. Equipped with a 3-phase electric motor, it ensures smooth and consistent operation.

Detail Information

Product Name: 750W Magnetic Drive Pump

Thread Interface (Inlet/Outlet): 1.5 Inch

Tube: 36 mm

Max. Capacity: 260 L/min

Max. Head: 18M

Standard Capacity: 120 L/min

Standard Head: 12M

Motor Output: 750W

Motor Phase: 3 Phase

Power: Electric

Usage: Water

The Magnetic Drive Circulation Pump operates with a magnetic coupling system, where the shaft and impeller are connected by a magnetic force, eliminating the need for traditional mechanical seals. This design ensures a completely sealed system. The torque motor drives the pump, and the working blades are activated by magnetic attraction. Unlike typical magnetic drive pumps, which are prone to damage when running dry, the MP Magnetic Drive Circulation Pump is specially designed to prevent this issue. It uses a special ceramic bearing formula with high abrasion and corrosion resistance, guaranteeing advanced and reliable safety performance. The sealless design of the circulating pump completely avoids the erosion and contamination issues associated with traditional mechanical seals, making it an ideal liquid pump for industrial equipment.

Applications

» Chemical Industry

Sodium carbonate production (hydrochloric acid, hypochlorous acid, secondary chemical products)

Fluoride and chemical fertilizer production

Circulation of reactive liquid in gas absorption towers

Grease extraction (sulfuric acid)

Waste acid substance recycling and reactivation

Transport of strong acids between chemical factories and transport vehicles

» Pharmaceutical Industry

Production of luminophor (EL) for semiconductors

Pesticide, medicine, and water treatment agent production

» Electroplating Industry

Circulation and filtration of electroplating liquids

» Photographic Processing

At-once photographic systems

X-film washing, black-and-white and color processing, and solid photographic development

» Electronics Industry

Production of chemical capacitors (erosion by alumina film)

Transport of electrolytes for dry battery and accumulator production

Etching circuit boards

Transfer of high-purity chemicals during semiconductor manufacturing

» Metal Industry

Treatment of aluminum oxide films

Wire stretching

Oil elimination and acid cleaning for steel rolling

Oil elimination and acid cleaning prior to vehicle painting

Production of oxidized titanium and rare-earth elements

» Mineral Industry

Transport and recycling of electrolyte in fusion metallurgy

Handling of waste liquids

» Food Industry

Gluconic acid production (hydrochloric acid)

Cooking oil extraction (sulfuric acid)

Potted fruit industry (hydrochloric acid)

» Medical Industry

Manufacture of artificial kidneys and hearts

Ultrasonic washing machines

Various medical equipment

» Water Treatment

Cleaning ion exchange resins

Pure water production equipment

Seawater desalination equipment

» Pollution Control

Wastewater treatment agents for medical liquid tanks

Waste liquid collection and transportation

Waste gas absorption equipment (deodorization and desulfurization before waste gas discharge)

» Other Applications

Silver recycling

Shi manufacturing

Laboratory ice-making machines

Drinking machines

Domestic boilers

Heating exchange systems

Solar energy systems

Dyeing laser systems

Water-spouting pools

Fish tank bearing ponds

Send your message to this supplier

FAQs

Similar Products

Related Searches

Products you might also like

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading , Manufacturer

Source: https://www.kosenvalve.com/750w-magnetic-drive-pump-3-phase-max-260-l-min-18m-head.html

Copyright © 2015-2026 China Manufacturers, CNMFRS.COM, All rights reserved.

谷歌优化(Google SEO)