Resilient Seated Butterfly Valve, API 609, EN 593, 2-96 Inch

Key Specifications / Features

As a prominent producer in China, we specialize in manufacturing resilient seated butterfly valves in compliance with API 609, EN 593, and MSS SP-67 standards. Our comprehensive range covers sizes from 2 to 96 inches and features construction from cast, ductile iron, stainless steel, and carbon steel. These valves are available with flange, lug, and wafer ends, providing versatility for various applications. Count on our resilient seated butterfly valves for reliable performance and durability.

Request a quote

Detail Information

Resilient Seated Butterfly Valve

Our factory's butterfly valves are versatile and suitable for a wide range of applications across various industries, including petroleum, chemicals, food processing, pharmaceuticals, papermaking, hydropower, shipping, water supply and drainage, metallurgy, and energy. These valves are designed to handle a variety of media, including corrosive gases, liquids, semi-liquids, and solid powders.

Operating Modes: Available with manual handle, worm gear drive, pneumatic, and electric actuators.

Diameter Range: From DN50 to DN2400 (2 to 96 inches).

These butterfly valves are engineered for durability and reliability in diverse environments and operational conditions.

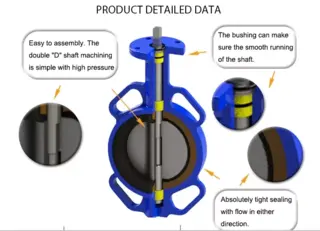

Resilient Seated Butterfly Valve-Features

- Separate Bushings: Ensure proper alignment of the shaft through the valve body and reduce operating torque.

- Blowout-Proof Design: The stem is fully retained by pins to the valve disc, preventing blowout and ensuring secure operation.

- Leakage Prevention: The stem is sealed by two separate O-rings and an integral seal in the seat, ensuring absolutely no external leakage throughout the valve's lifespan.

- Resilient Seat Surface: The replaceable seat extends past the valve face, eliminating the need for gaskets on flanged installations and significantly reducing installation time.

- Reduced Torque: Allows for the use of smaller, more economical actuators while still meeting close-off requirements.

Resilient Seated Butterfly Valve-Specifications and Standard

1. Connection: Flange type, Lug type, Wafer type, Groove End type

2. Design Standard: API 609, BS EN 593, GB/T 12238, MSS SP-67

3. Face to Face Standard: API 609, BS 5155, ISO 5752

4. Flange Drilling: ANSI B16.1, BS 4504, DIN PN10/PN16, JIS 5K, 10K, 16K

5. End Flange: DIN PN10/16/25, ANSI B16.1, BS 4504, ISO PN10/16, JIS B2212/2213, BS 5155

6. Top Flange: ISO 5211

7. Test: API 598, ISO 9001, ASTM, ANSI, DIN, BS, JIS

8. Coating: Epoxy powder coating, or coating as customers' requirement

9. Certificate: ISO 9001:2000, ISO 2531, EN545, QS-9000 SGS, EN 598, BS 4772, DIN 3352

10. Body Material:Cast Iron: ASTM A126 CL. B, DIN 1691 GG25, EN 1561 EN-GJL-200, GB 12226 HT200

Ductile Iron: ASTM A536 65-45-12, DIN 1693 GGG40, EN 1563 EN-GJS-400-15, GB 12227 QT450-10

Stainless Steel: ASTM A351 CF8, CF8M, CF3, CF3M

Carbon Steel: ASTM A216 WCB

Stem:Zinc Plated Steel, Stainless Steel: ASTM A276 Type 316, Type 410, Type 420, ASTM A582 Type 416

Disc:Ductile Cast Iron (Nickel plated): ASTM A536 65-45-12, DIN 1693 GGG40, EN 1563 EN-GJS-400-15, GB 12227 QT450-10, Stainless Steel: ASTM A351 CF8, CF8M, CF3, CF3M; EN 1.4408, 1.4469, 1.4501, AL-Bronze: ASTM B148 C95400