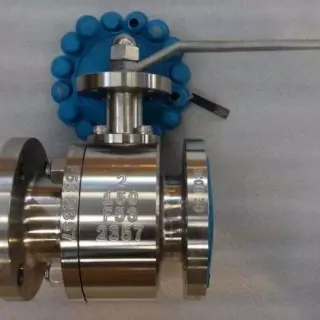

ASTM A182 F53 Floating Ball Valve, API 6D, 2-1/2 IN, 1500 PSI

Key Specifications / Features

The ASTM A182 F53 Floating Ball Valve, supplied with a forged duplex stainless steel body, features a robust two-piece design compliant with API 6D standards. Sized at 2-1/2 inches with a pressure rating of 1500 PSI, it is engineered for reliability in high-pressure environments. Equipped with an RPTFE seat for superior sealing and butt weld (BW) ends for secure pipeline integration, this valve ensures efficient performance and minimal leakage, making it ideal for demanding industrial applications requiring durability and resilience.

Request a quote

Detail Information

Forged Duplex Stainless Steel Floating Ball Valve

Valve description: Ball valve, floating type, soft seat, bolted bonnet, two pieces 2PC, forged Duplex stainless steel, full bore, anti-static, fire-safe design, anti-stem blowout

Design & Manufacture: API 6D

Body material: ASTM A182 F53

Ball material: ASTM A182 F53

Nominal diameter: 2-1/2 Inch, DN65

Nominal class: 1500 PSI

End connection: BW (Butt Weld)

Seat Material: RPTFE

Face to face: ASME B16.10

Test and inspection: API 598

Mode of operation: Lever

The Forged Floating Ball Valve is available in both 2-piece and 3-piece body designs, constructed from forged steel. Connection types include FF (Flat Face), RF (Raised Face), RTJ (Ring Type Joint) flange, NPT (National Pipe Thread), BW (Butt Weld), and SW (Socket Weld) ends. Options for reduced bore and full port configurations are available upon request.

We manufacture the following ball valves:

Side Entry Design Forged Ball Valves

End Entry Floating Ball Valve

Long Pattern Forged Ball Valve

Short Pattern Forged Ball Valve

SIZE RANGE AND PRESSURE CLASS

Size Range: 1/2 Inch to 8 Inch (DN15-DN200)

Pressure Range: Class 150 LB to 600 LB (PN16-PN100)

DESIGN STANDARDS

Design / Manufacture: MFG, API 6D, API 608, ISO 17292, EN-12516, ASME B16.34, DIN 3357, EN 13709, GB/T 12237, BS 5351

Face to Face Length (Dimension): MFG, API 6D, ASME B16.10, EN 558-1, GB/T 12221, DIN 3202

Flanged Dimension: ASME B16.5, EN 1092-1, BS 4504, DIN 2501

Testing: API 598, API 6D, EN 12266-1, EN 1074-1, ISO 5208, BS 6755-1

TECHNICAL FEATURES

Valve description: Ball valve, floating type, soft seat, bolted bonnet, two pieces 2PC, forged Duplex stainless steel, full bore, anti-static, fire-safe design, anti-stem blowout

Design & Manufacture: API 6D

Body material: ASTM A182 F53

Ball material: ASTM A182 F53

Nominal diameter: 2-1/2 Inch, DN65

Nominal class: 1500 PSI

End connection: BW (Butt Weld)

Seat Material: RPTFE

Face to face: ASME B16.10

Test and inspection: API 598

Mode of operation: Lever

The Forged Floating Ball Valve is available in both 2-piece and 3-piece body designs, constructed from forged steel. Connection types include FF (Flat Face), RF (Raised Face), RTJ (Ring Type Joint) flange, NPT (National Pipe Thread), BW (Butt Weld), and SW (Socket Weld) ends. Options for reduced bore and full port configurations are available upon request.

We manufacture the following ball valves:

Side Entry Design Forged Ball Valves

End Entry Floating Ball Valve

Long Pattern Forged Ball Valve

Short Pattern Forged Ball Valve

SIZE RANGE AND PRESSURE CLASS

Size Range: 1/2 Inch to 8 Inch (DN15-DN200)

Pressure Range: Class 150 LB to 600 LB (PN16-PN100)

DESIGN STANDARDS

Design / Manufacture: MFG, API 6D, API 608, ISO 17292, EN-12516, ASME B16.34, DIN 3357, EN 13709, GB/T 12237, BS 5351

Face to Face Length (Dimension): MFG, API 6D, ASME B16.10, EN 558-1, GB/T 12221, DIN 3202

Flanged Dimension: ASME B16.5, EN 1092-1, BS 4504, DIN 2501

Testing: API 598, API 6D, EN 12266-1, EN 1074-1, ISO 5208, BS 6755-1

TECHNICAL FEATURES

- Fully Compliant to ASME B16.34

- Fully Compliant to API 608, API 6D, BS 5351

- API 607 6th Edition Fire-Safe

- All Models are NACE MR0175 Compliant

- Submerged Packing System & Direct Mount Actuation

- Standard ISO Actuator Mounting Pads on All Sizes

- Standard Locking Stainless Steel Handles, Locking Bracket

- Second Generation PTFE Seats Provide Higher Operating Temperatures

- Standard Electrically Grounded Ball & Stem

- All Sizes use Body Studs & Nuts for Ease of Disassembly

- Forged material for dependable quality and performance

- ASTM A961 Corrosion Protective Coating

- Swing Out Construction for ease of installation

- ISO Integral Mounting Pad

- Anti-Static Device

- Blowout Proof Stem