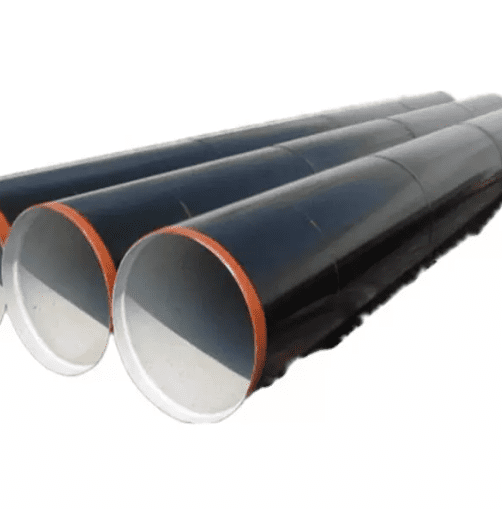

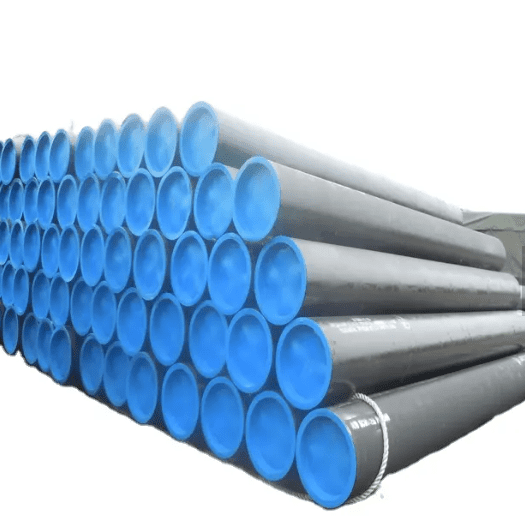

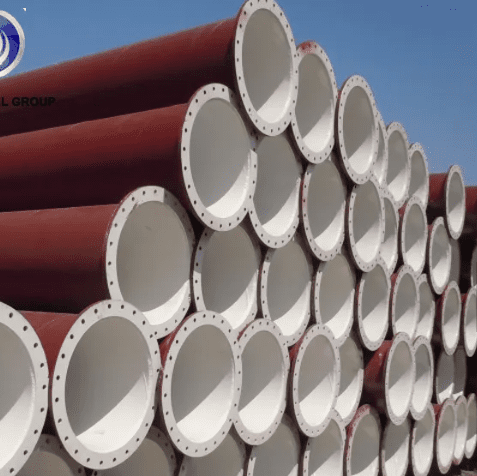

Carbon Steel Price Per Meter API 5L Grade B 3PE Coated API5l X52 Seamless Pipe 18’ SCH40

Key Specifications / Features

China manufacturer of Carbon Steel Price Per Meter API 5L Grade B 3PE Coated API5l X52 Seamless Pipe 18’ SCH40

Request a quote

Detail Information

Standard: API 5L-2009 ISO 3183-2007 DIN 30670 ( Coating)

Steel Grades: Gr. B X42 X46 X52 X56 X60 X65 X70 L245 L290 L320 L360 L390 L415 L450 L480

Size Range: OD:1/2” TO 36”. WT: 3mm To 45mm

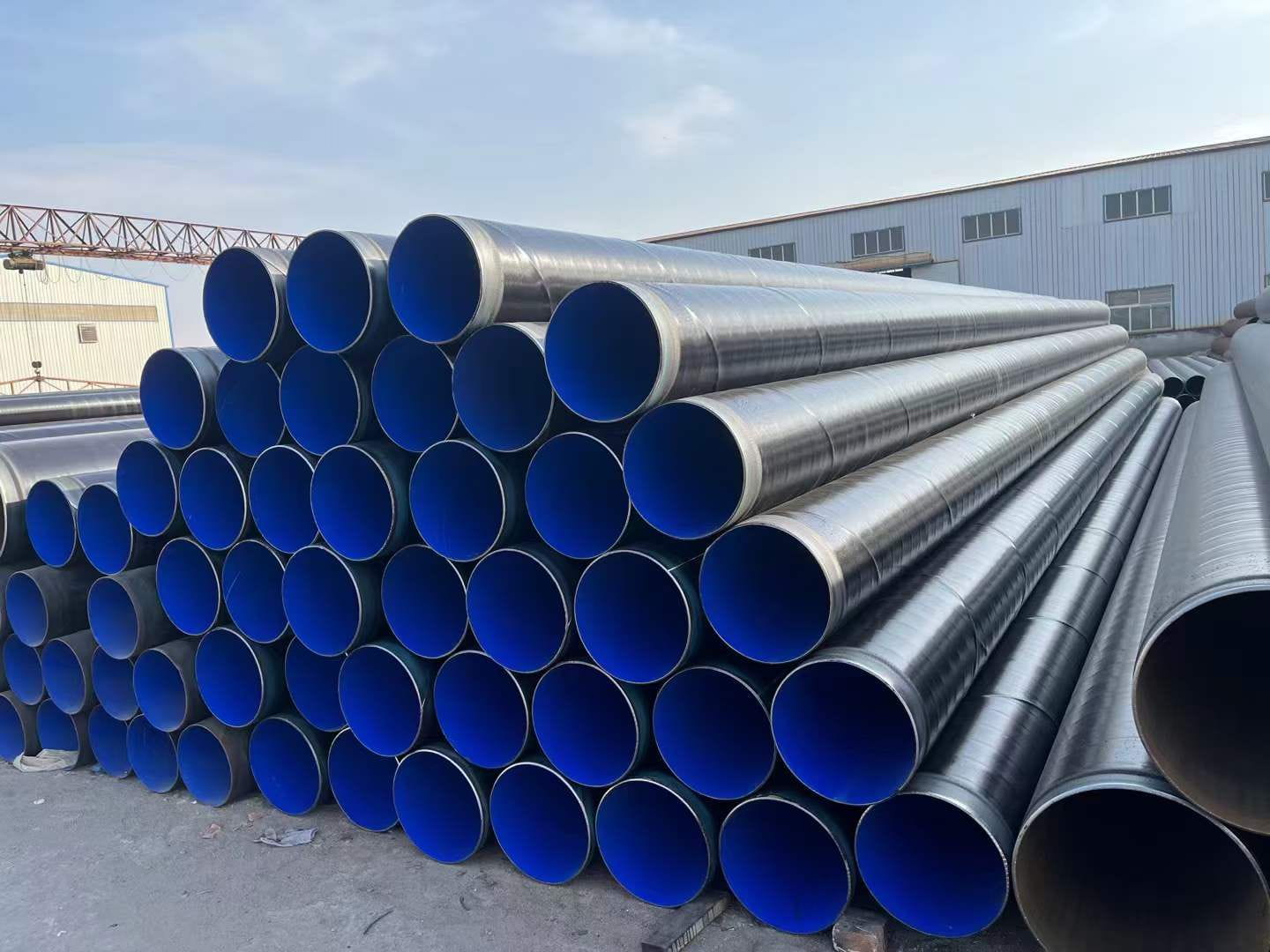

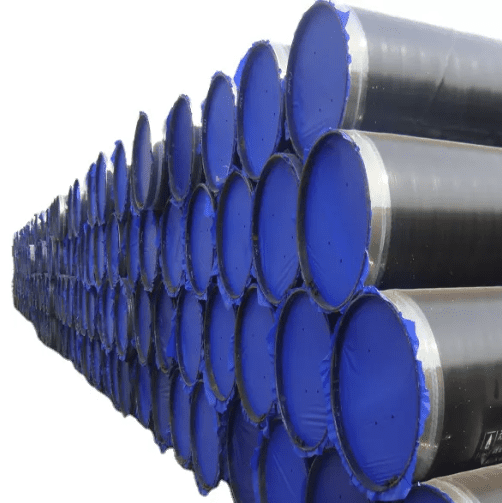

Coating Thickness: 2mm- 5mm

Manufacturing Process : Hot Rolled / ERW /LSAW

Application:The external coating is mainly used for anti-corrosion protection for liquid pipes before burying.Such pipes has been widely used in rugged environment

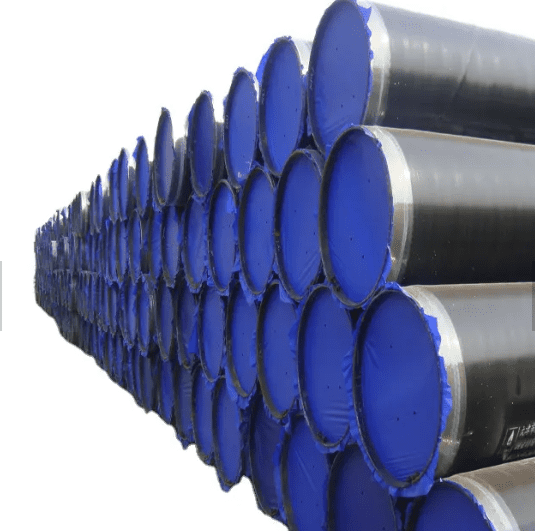

Packing: External Black Painting ,Both Side With End Caps, In Bundles by Steel Strips,Covered by Waterproof.

Steel Grades: Gr. B X42 X46 X52 X56 X60 X65 X70 L245 L290 L320 L360 L390 L415 L450 L480

Size Range: OD:1/2” TO 36”. WT: 3mm To 45mm

Coating Thickness: 2mm- 5mm

Manufacturing Process : Hot Rolled / ERW /LSAW

Application:The external coating is mainly used for anti-corrosion protection for liquid pipes before burying.Such pipes has been widely used in rugged environment

Packing: External Black Painting ,Both Side With End Caps, In Bundles by Steel Strips,Covered by Waterproof.

| DELIVERY CONDITION | |||||||

| Steel grade | Delivery condition | ||||||

| BNS(L245NS) | Normalizing rolled, normalizing formed, normalized, normalized and tempered | ||||||

| X42NS(L290NS) | Normalizing rolled, normalizing formed, normalized, normalized and tempered | ||||||

| X46NS(L320NS) | Normalizing rolled, normalizing formed, normalized, normalized and tempered | ||||||

| X52NS(L360NS) | Normalizing rolled, normalizing formed, normalized, normalized and tempered | ||||||

| BQS(L245QS) | Quenched and tempered | ||||||

| X42QS(L290QS) | Quenched and tempered | ||||||

| X46QS(L320QS) | Quenched and tempered | ||||||

| X52QS(L360QS) | Quenched and tempered | ||||||

| X56QS(L390QS) | Quenched and tempered | ||||||

| X60QS(L415QS) | Quenched and tempered | ||||||

| MECHANICAL PROPERTIES | |||||||

| Steel Grade | Strtch Performance | Impact energy(J) |

Hardness | ||||

| Yield strength | Tensile strength | Elongation | |||||

| Mpa | Mpa | % | Min | Max | |||

| Min | Max | Min | Max | ||||

| BNS(L245NS) BQS(L245QS) | 245 | 450 | 415 | 760 | As per standard |

27 | 22HRC OR 250HV10 |

| X42NS(L290NS) X42Q(L290QS) | 290 | 495 | 415 | 760 | 27 | ||

| X46NS(L320NS) X46Q(L320QS) | 320 | 525 | 435 | 760 | 27 | ||

| X52NS(L360NS) X52Q(L360QS) | 360 | 530 | 460 | 760 | 27 | ||

| X56QS(L390QS) | 390 | 545 | 490 | 760 | 27 | ||

| X60QS(L415QS) | 450 | 600 | 520 | 760 | 27 | ||

| CORROSION RESISTANCE TEST | |||||||

| Corrosion resistance test | Test method | Solution | Benchmark stress |

Test duration (hou) |

Test result | ||

| SSC test | NACE TM0177-2005 |

Solution A | SMYSx72% | 720 | No break | ||

| HIC test | NACE TM0284-2003 |

Solution A | - | 96 | CSR≦2.0% Qualified CTR≦5.0% Qualified CLR≦15.0% Qualified |

||