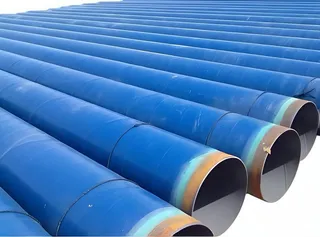

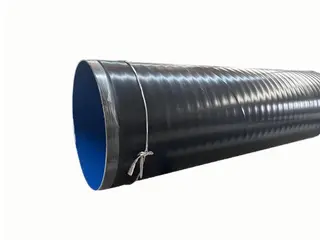

API5l X42 X50 Psl1 Psl2 Steel Pipe with 3PE Coating

Key Specifications / Features

Detail Information

|

Commodity |

Coated Steel Pipe 3Lpe Coating Fusion Bonded Epoxy Coating |

|

|

Size |

O.D |

|

|

Thickness |

||

|

Length |

||

|

Standards |

API 5L-2009; ISO3183-2007;DIN30670,30678(Coating) |

|

|

Steel Grades |

Gr. A GrBx42x46x52x56x60x65x70, L245 etc. |

|

|

internal coating |

cement mortar lining; bitumen coating; liquid epoxy; FBE |

|

|

external coating |

3lpe; 2lpe; 2LPP; FBE; Bitumen; enamel tape hot-applied; liquid epoxy coating; polyurethane insulated coating. |

|

|

Manufacture Process |

Hot rolled/ Hot Expansion |

|

|

Main Application |

The external coating is mainly used for anti-corrosion protection for liquid pipes before burying. Such pipe has been widely used in rugged environment. |

|

|

Min quantity |

2 tons, more quantity price will be lower. |

|

|

Packing |

both sides with end caps, in bundles by steel strips. In hexagonal shape bundles wrapped with strong steel trip 2MT/bundle. |

|

|

Delivery time |

20-25days after receiving your deposit or L/C. |

|

|

Payment |

TT or 100% Irrevocable LC at sight. We can discuss. |

|

|

External Coating |

|

|

Coating type |

Coating Standard |

|

3LPE/3LPP |

DIN30670-1991,CAN/CSA Z245,21-2010,ISO21809-1-2009 SY/T 0413-2002,GB/T23257-2009 |

|

2LPE/2LPP |

SY/T 0315-2002,GB/T23257-2009,ISO21809-1-2009 |

|

FBE(Fusion-bond epoxy) |

SY/T 0315-2005,AWWA C213-2001,CAN/CSAZ245.20-2010,ISO218909-2-2007,API RP5L9-2001 |

|

Bitumen coating Enamel &Tape hot-applied |

BS534-1990,AWWA203-2002,AWWA214-2000 |

|

Liquid epoxy coating |

AWWWA C210-2007 |

|

Polyurethane insulated coating |

SY/T0415-1996,CJ/T114-2000.EN253-1994 |

|

Internal Coating |

|

|

Liquid Epoxy Coating |

AWWAC210-2007 |

|

FBE |

AWWAC213-2001 |

|

Cement Mortar Lining |

BS534-1990,AWWA C205-2001 |

|

Bitumen Coating |

BS534-1990 |