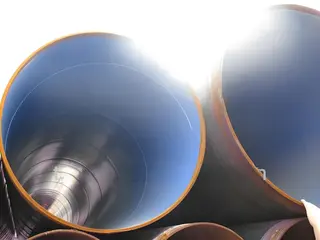

3LPE COATED PIPE, API 5L PSL1, API 5L X42, SMLS, 12 In, SCH60,12M

Key Specifications / Features

China,3LPE COATED PIPE, API 5L PSL1, API 5L X42, SMLS, 12 In, SCH60,12M

Request a quote

Detail Information

O.D: DN60-DN1200 (2”-48”)

W.T: SCH10- XXS (2.11-60mm)

Grade: 20#,16Mn,Q235,Q345,X42-X70,Q235,A,B,Gr.2, CC60,CC65,S235,S275,S355

Manufacture method: Seamless pipe (Hot rolled, hot expended, cold drawn,cold rolled), welded pipe (ERW/HFW electric resistance/high frequency welded, SSAW spiral submerged arc welded, LSAW longitudinal submerged arc welded )

Coating type: 3LPE,3LPP, FBE, Epoxy, Polyurethane, CWC

Test type: Peeling strength, holiday test..

Service life:30 years.

Devliery Condition: As Rolled, As Welded, +N,+M,+QT

Marking: As per standard & customer's requirements

Packing: Caps on two ends of every pipe to protect the end bevel, In hexagonal shape bundles wrapped with strong steel trip 2MT/bundle for size below DN200/8”, bare packing for DN200/8” and above .

Application: Oil and gas industry, chemical industry, water convey and some special strong corrosion environment

W.T: SCH10- XXS (2.11-60mm)

Grade: 20#,16Mn,Q235,Q345,X42-X70,Q235,A,B,Gr.2, CC60,CC65,S235,S275,S355

Manufacture method: Seamless pipe (Hot rolled, hot expended, cold drawn,cold rolled), welded pipe (ERW/HFW electric resistance/high frequency welded, SSAW spiral submerged arc welded, LSAW longitudinal submerged arc welded )

Coating type: 3LPE,3LPP, FBE, Epoxy, Polyurethane, CWC

Test type: Peeling strength, holiday test..

Service life:30 years.

Devliery Condition: As Rolled, As Welded, +N,+M,+QT

Marking: As per standard & customer's requirements

Packing: Caps on two ends of every pipe to protect the end bevel, In hexagonal shape bundles wrapped with strong steel trip 2MT/bundle for size below DN200/8”, bare packing for DN200/8” and above .

Application: Oil and gas industry, chemical industry, water convey and some special strong corrosion environment