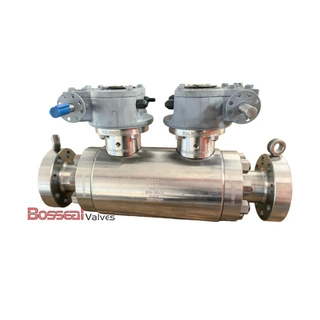

API 6D DBB Trunnion Ball Valve, A182 F316, 4 Inch, CL300, RF

Key Specifications / Features

Detail Information

Valve Description:

181302025 DBB Trunnion Ball Valve, Double Block and Bleed Ball Valve

Design Standard: API 6D, BS 5351

Sizes: 4 Inch, DN100, 100 mm

Nominal Class: Class 300 LB, PN50

Seat Insert: RPTFE, DEVLON, NYLON, PEEK

Structure: Full Welded

Operation: Lever

Test and Inspection: API 598, API 6D

Bore Type: Full Bore or Reduced Bore

Body Material: ASTM A182 F316, ASTM A182 F304, ASTM A350 LF2, ASTM A105N, ASTM A182 F51, ASTM A182 F53, F55, Inconel 625

Trim Material: ASTM A182 F6A, F304, F316, F51, F53, F55, A105+ENP, LF2+ENP

Face to Face: ASME B16.10

End Connection: RF Flanged

Key Features: Double Block&Bleed(DBB), Anti-static Device, Fire Safe, Anti-Blowout Stem, Emergency sealant injection, Low Emission(Optional), DIB (Optional), full welded bonnet, Double Ball/Twin Ball

Product Range:

Body Material: Carbon Steel, Stainless Steel, Alloy Steel

Normal Diameter: 1/2 Inch - 48 Inch (DN15 - DN1200)

Pressure Range: Class 150 LB - 2500 LB

End Connection: RF, RTJ, BW, HUB

Working Temperature: -26°C - +150°C

Operation: Manual(lever, gear), Pneumatic Actuator, Motor Actuator

DESIGN FEATURES:

• Renewable solid wedges.

• Integral seats.

• High-Tensile bronze alloy stem.

• Stems are rotating/rising design.

• Each valve is shell and seat pressure tested per industry standard MSS SP-80.