10 Inch Globe Valves, BS 1873, Aluminum Bronze, CL150 LB, RF

Key Specifications / Features

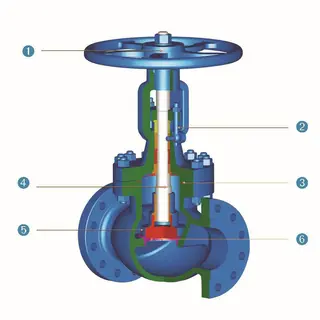

We are a reliable supplier of BS 1873 globe valves, offering high-performance solutions for demanding applications. This 10-inch (DN250), Class 150 LB valve is constructed with a robust aluminum bronze body and trim made from ASTM B148 C95800, providing exceptional resistance to corrosion in marine and industrial environments. Featuring a bolted bonnet and OS&Y (outside screw and yoke) design, it ensures reliable operation and easy maintenance. Available with flat face (FF) or raised face (RF) flanged ends, this globe valve is ideal for fluid control systems requiring durability, safety, and long-lasting performance.

Detail Information

Valve Description:

187305007 Aluminum Bronze Globe Valve

Design Standard: BS 1873, API 623

Structure: Bolted Bonnet/Pressure Seal Bonnet

Nominal Size: 10 Inch, DN250

Nominal Class: 150 LB

Bore Type: Standard Bore

End Connection: FF or RF Flanged

Operation: Handwheel/Gear

Body Material: ASTM B148 C95800

Trim Material: ASTM B148 C95800

Face to Face: ASME B16.10

Test and Inspection: API 598

Key Features: OS&Y, Screwed-in Back seat, Rising Stem, Non-rising Handwheel, Flexible Wedge, Low Emission Design, Aluminium bronze for sea water service

Product Range:

Body Material: Aluminum Bronze

Normal Diameter: 2 Inch - 24 Inch (DN50 - DN600)

Pressure Range: Class 150 LB - Class 300 LB

End Connection: RF/FF

Working Temperature: -29°C - +400°C

Operation: Handwheel/Gear/Motor

A globe valve is a multi-turn control valve commonly used in pipelines for regulating flow, especially in small-diameter piping. It features a movable disc (plug) connected to a stem, with a seat ring centered and parallel to the pipe axis. Due to high torque requirements, it’s not ideal for large sizes or high-pressure on/off applications. Its shorter stem travel reduces seat wear, offering a longer service life compared to gate valves. Available with hard-faced or soft seats, globe valves are suitable for throttling and flow control of water, steam, oil, and gas.