What is an Open Width Knitting Machine?

Introduction: Redefining Circular Knitting

In the ever-evolving textile industry, the demand for smoother, high-quality fabrics with minimal creases has fueled continuous innovations in knitting technology. One such advancement that has gained widespread popularity among textile manufacturers worldwide is the Open Width Knitting Machine.

Unlike traditional tubular knitting machines that produce fabric in a tube form, open width circular knitting machines are engineered to deliver fabric in an open, flat form, eliminating the need for additional cutting and seaming processes. This innovative design not only enhances production efficiency but also ensures a smooth, wrinkle-free finish that meets the highest industry standards.

Whether you’re a seasoned textile producer, a fabric technologist, or simply curious about how your favorite stretch jersey T-shirt maintains its perfect shape, understanding how an open width knitting machine works provides valuable insight into modern fabric manufacturing.

How an Open Width Circular Knitting Machine Works

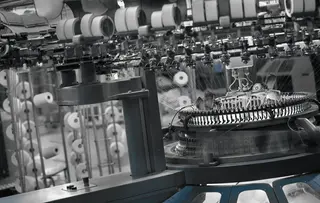

At its core, an open width circular knitting machine is based on the traditional single jersey tubular knitting machine. However, it incorporates key mechanical modifications that allow it to deliver fabric in an open width format.

One of the most notable features is the installation of a special open width fabric take-down device, which cuts and spreads the tubular fabric into a flat form immediately after knitting. This prevents creases and folding marks that are common when tubes are slit open post-production.

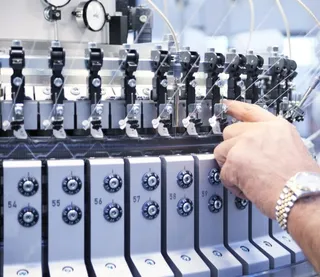

The machine’s circumference is marked with scale indicators to maintain precise distance between fabric edges. This unique configuration ensures that the machine operates with inch-by-inch accuracy, resulting in consistent fabric tension and uniform texture across the entire roll.

A defining characteristic of many modern open width knitting machines is the Central Stitch Adjustment (CSA) mechanism. This feature makes it exceptionally easy for operators to adjust fabric density accurately, ensuring that the final fabric meets specific requirements for size, weight, and texture.

These structural and operational enhancements translate into significant practical benefits for textile mills: from prolonging the life of needles and equipment to minimizing material wastage and increasing overall profit margins.

Open Width Knitting: Single Jersey vs. Double Jersey

Open width knitting machines are broadly categorized into two main types:

1. Single Jersey Open Width Knitting Machine

2. Double Jersey Open Width Knitting Machine

Each type is designed to cater to different fabric requirements and end uses.

Single Jersey Open Width Knitting Machine

The single jersey open width knitting machine is renowned for its versatility and ease of operation. It is capable of processing a wide variety of yarns and fibers, including synthetic fibers, elastic fabrics, double thread velvet, and elastic silk cotton. This makes it ideal for producing plated fabrics, urethane elastic fabrics, and other lightweight, stretchable textiles.

One of the most appreciated features is the ability to automatically cut the fabric using the integrated open width take-down device. This not only ensures that the fabric is crease-free but also saves time and labor that would otherwise be spent cutting tubes open manually.

Key Features of Single Jersey Open Width Machines

Adjustable Fabric Size, Density, and Thickness: Operators can easily change settings to produce different weights and finishes.

Extended Equipment Life: The smooth operation reduces stress on needles and mechanical components.

Central Stitch Adjustment: Allows precise control of stitch tightness and fabric density.

High Accuracy: Scale marks maintain precise alignment for uniform fabric edges.

Enhanced Gearing Systems: Provide smoother operation and easy adjustment.

Less Waste, Higher Profits: Minimizing fabric loss translates into cost savings.

Wrinkle-Free Output: The design ensures there is no break in the center or on the surface of the fabric.

Double Jersey Open Width Knitting Machine

For heavier fabrics or more complex knits, the double jersey open width knitting machine is the go-to solution. These machines are typically equipped with high-speed motors and large-diameter cylinders, which allow them to handle thicker yarns and produce fabrics with greater structural integrity.

In addition to the standard features of single jersey machines, double jersey models include a roller speed adjustment device that maintains uniform and stable knitting tightness. This is critical for producing double-layered fabrics like interlock knits, rib knits, and other structured textiles that require balanced tension.

The double jersey machine also integrates an automatic cutting system, which significantly reduces unnecessary fabric loss during the take-down process. An automatic cloth collecting stick rolls up the fabric neatly, accommodating cloth with diverse sizes for downstream processing.

Key Features of Double Jersey Open Width Machines

Safe Shutdown Function: Enhances operator safety during maintenance and emergencies.

Uniform Knitting Tightness: Ensures consistent fabric quality.

Automatic Cloth Rolling: Simplifies handling of fabrics of various sizes.

High-Speed Motor and Large Cylinder: Delivers greater productivity.

Automatic Cutting System: Reduces fabric waste.

Broad Material Compatibility: Can handle cotton, synthetic fibers, silk, artificial wool, mesh, and elastic cloth.

Wrinkle-Free Finish: Prevents creases both in the center and on the surface of the fabric.

Benefits of Using Open Width Knitting Machines

The advantages of investing in an open width knitting machine go beyond just producing wrinkle-free fabric. Let’s break down some of the key benefits:

1. Improved Fabric Quality

By eliminating the need for post-production slitting and spreading, open width knitting machines produce fabric that retains its original texture and elasticity. This is particularly valuable for stretch fabrics where uniform tension is critical.

2. Enhanced Production Efficiency

Automatic cutting and cloth collecting systems reduce manual handling, minimizing labor costs and speeding up the production process.

3. Cost Savings and Waste Reduction

Machines are designed to minimize unnecessary fabric loss during take-down and cutting. This means more usable fabric per roll and higher profitability for manufacturers.

4. Versatility

Whether you’re producing lightweight jersey knits for T-shirts or heavier double jersey knits for sportswear and outerwear, open width knitting machines offer the flexibility to handle a wide range of materials and fabric constructions.

5. Longer Equipment Life

The smooth, inch-by-inch operation reduces mechanical strain on needles and other components, extending the service life of the machine.

Key Applications in the Textile Industry

The fabrics produced on open width knitting machines are widely used in various sectors:

Fashion and Apparel: T-shirts, dresses, leggings, activewear, and other garments benefit from the smooth, crease-free finish.

Sportswear: Stretch fabrics and double knits used in sports and performance wear often rely on the high tension stability provided by open width machines.

Home Textiles: Bedsheets, pillowcases, and decorative fabrics can be produced with consistent width and no creases.

Industrial Textiles: Elastic and mesh fabrics used in medical or industrial applications also benefit from the high accuracy and material savings.

Innovations and Future Trends

As sustainability and automation continue to shape the textile industry, open width knitting machines are evolving to integrate smart technologies such as digital controls, real-time monitoring, and predictive maintenance systems.

Manufacturers are also focusing on developing energy-efficient models that reduce power consumption without compromising output. Additionally, there is a growing emphasis on modular machine designs that allow textile mills to adapt their equipment easily for new fabric types or changing market demands.

With the global push for eco-friendly production, minimizing fabric waste and maximizing usable output has become more important than ever — an area where open width knitting machines already excel.

Choosing the Right Open Width Knitting Machine

For textile mills considering an upgrade or new investment, choosing between single jersey and double jersey open width knitting machines depends on several factors:

Product Range: What types of fabrics are you producing? Do you need to handle elastic fibers, double knits, or specialty yarns?

Production Volume: High-speed double jersey models may be preferable for large-scale production.

Budget: Consider not just the upfront machine cost but also long-term savings through reduced waste and maintenance.

After-Sales Support: Reliable technical support and spare parts availability are crucial for minimizing downtime.

Conclusion: Open Width Knitting Machines as a Competitive Advantage

From boutique knitting mills to large-scale textile factories, open width knitting machines have become an indispensable part of modern fabric production. Their ability to deliver high-quality, crease-free fabrics with minimal waste gives manufacturers a clear edge in an increasingly competitive market.

With ongoing innovations enhancing speed, efficiency, and sustainability, these machines are poised to remain a vital solution for fabric producers aiming to meet the ever-evolving demands of fashion, sportswear, and technical textiles.

Whether you’re planning to expand your production line or optimize your existing setup, understanding the full potential of open width knitting technology can help you make informed decisions that drive your business forward — one smooth, perfectly knitted yard at a time.

Send your message to this supplier

Related Articles from the Supplier

What is an Open Width Knitting Machine?

- Jul 07, 2025

What Is a Jacquard Knitting Machine?

- Nov 25, 2024

Related Articles from China Manufacturers

What Is an Express Cabinet Lock?

- Aug 22, 2023

What is an ABS plastic locker?

- Jan 05, 2019

What Is An Advantage Of A Butterfly Control Valve?

- Jun 24, 2024

What is an Explosion Proof Electric Actuator?

- Feb 28, 2025

What Is An Accumulator?

- May 17, 2022

What is an EV Charging Pile?

- Jan 15, 2025

Related Products Mentioned in the Article

Supplier Website

Source: https://www.xmnyuanda.com/news/what-is-an-open-width-knitting-machine.html