Understanding the Operating Principle of Circular Knitting Machines

Introduction

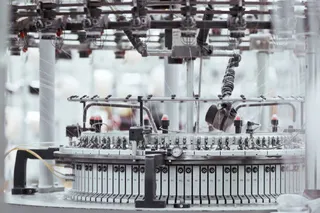

The circular knitting machine is one of the most important innovations in modern textile manufacturing. By enabling continuous, high-speed production of knitted fabrics in tubular form, it has transformed the way garments and technical textiles are produced worldwide. From everyday T-shirts and underwear to sportswear, home textiles, and industrial fabrics, circular knitting machines support a wide range of applications with outstanding efficiency and consistency.

Unlike flat knitting machines, which produce fabric in a back-and-forth motion, circular knitting machines operate with needles arranged in a circular configuration. This design allows the machine to knit fabric continuously, resulting in higher productivity, smoother fabric structures, and reduced material waste. As global demand for knitted fabrics continues to grow, understanding the operating principle of circular knitting machines is essential for manufacturers, engineers, and textile professionals seeking to improve quality, efficiency, and innovation in production.

What Is a Circular Knitting Machine?

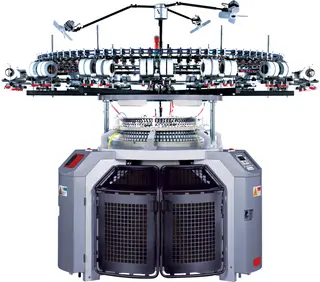

A circular knitting machine is a textile machine that produces knitted fabric using needles mounted on a rotating circular needle bed. As the machine runs, yarn is fed continuously to the needles, which form interlocking loops to create a knitted structure. The finished fabric is produced in tubular form and is continuously drawn downward by a take-up system.

Circular knitting machines are widely used because they offer:

- High production speed

- Uniform fabric quality

- Flexibility in fabric design

- Compatibility with various yarn types

They are commonly used for producing single jersey, rib, interlock, jacquard, fleece, terry, and other specialized knitted fabrics.

Basic Working Principle of Circular Knitting Machines

At its core, the operating principle of a circular knitting machine is based on loop formation. Yarn is fed to a series of needles arranged around a rotating cylinder (and, in some machines, an additional dial). As the needles move up and down along predefined cam tracks, they catch the yarn, form loops, and interlock these loops with previously formed ones. This continuous looping action creates a knitted fabric structure.

The machine operates in a synchronized cycle involving needle movement, yarn feeding, loop formation, and fabric take-up. Each component plays a specific role, and precise coordination between them is essential to produce consistent, high-quality fabric.

Main Components of a Circular Knitting Machine

Understanding the operating principle requires familiarity with the key components that make up the machine.

1. Needle Bed (Cylinder and Dial)

The needle bed is the core structure that holds the knitting needles. In circular knitting machines, the needle bed usually consists of two main parts:

- Cylinder: The cylinder is the vertical, rotating component that holds the majority of the needles. These needles move up and down within slots in the cylinder to form loops. Single jersey machines typically use only a cylinder.

- Dial: The dial is a horizontal needle bed located above the cylinder. It holds additional needles and works together with the cylinder needles to produce more complex structures such as rib and interlock fabrics.

The combination of cylinder and dial allows for greater fabric variety and improved structural stability.

2. Knitting Needles

Knitting needles are the most critical elements in the fabric-forming process. They are responsible for catching the yarn and forming loops. Circular knitting machines typically use latch needles, although compound needles may also be used in certain applications.

Key characteristics of knitting needles include:

- Precision-engineered shape for smooth movement

- High-strength materials, usually hardened steel

- Various gauges (needle densities) to control fabric fineness

As the machine operates, the needles follow cam tracks that guide them through different positions: clearing, feeding, looping, and knocking-over. This controlled motion is what enables consistent loop formation.

3. Cam System

The cam system governs the movement of the needles and is central to the operating principle of the machine. Cams are specially shaped metal tracks that direct the vertical motion of the needles as the cylinder rotates.

Different types of cams include:

- Raising cams, which lift the needles to catch yarn

- Lowering cams, which pull needles down to form loops

- Clearing cams, which ensure old loops are released

By adjusting the cam arrangement, manufacturers can create different stitch types and fabric structures. The cam system directly determines stitch length, fabric density, and overall fabric appearance.

4. Yarn Feeding System

The yarn feeding system supplies yarn to the needles in a controlled and continuous manner. Yarn feeders are positioned around the circumference of the machine and deliver yarn precisely at the point where needles are ready to receive it.

Modern circular knitting machines may be equipped with:

- Multiple yarn feeders for higher productivity

- Positive feed systems for accurate yarn tension control

- Electronic yarn monitoring devices

Proper yarn feeding ensures uniform loop formation, reduces yarn breakage, and improves fabric consistency.

5. Sinkers

Sinkers are thin metal elements positioned between needles. They play a vital role in loop formation and fabric control. While the needles move vertically, sinkers move horizontally to hold down the fabric and assist in forming stable loops.

The main functions of sinkers include:

- Holding the fabric during needle movement

- Helping define loop size

- Improving fabric surface quality

Without sinkers, it would be difficult to maintain consistent fabric structure, especially at high production speeds.

6. Take-Up and Fabric Winding System

Once the loops are formed, the knitted fabric must be continuously removed from the knitting zone. This is the role of the take-up system.

The take-up mechanism:

- Pulls the fabric downward evenly

- Maintains constant fabric tension

- Winds or collects the finished fabric

Proper take-up tension is essential, as excessive tension can distort fabric structure, while insufficient tension may cause defects or uneven knitting.

7. Drive and Control System

Modern circular knitting machines are driven by powerful motors and controlled by advanced electronic systems. The drive system ensures smooth and stable rotation of the cylinder, while the control system synchronizes all machine functions.

Key features of modern control systems include:

- Touchscreen interfaces

- Electronic stitch length adjustment

- Pattern programming and storage

- Real-time monitoring and fault detection

These systems significantly enhance productivity, accuracy, and operational flexibility.

Step-by-Step Operating Process for Circular Knitting Machine

The operating principle of a circular knitting machine can be summarized through the following sequence:

Yarn Supply

Yarn is fed from cones through tension devices and yarn feeders to the knitting zone.

Needle Clearing

As the cylinder rotates, needles are raised by the clearing cam to release old loops.

Yarn Feeding

The yarn feeder delivers yarn to the open hook of each needle.

Loop Formation

The needles descend under cam control, pulling the new yarn through the old loop.

Knock-Over

The old loop slides off the needle, forming a new knitted loop.

Fabric Take-Up

The newly formed fabric is drawn downward by the take-up system.

This cycle repeats continuously at high speed, producing fabric in a seamless tubular form.

Types of Circular Knitting Machines and Their Principles

While the fundamental operating principle of circular knitting machines remains the same, they can be classified into different types based on their structure, function, and fabric applications.

Single Jersey Circular Knitting Machines

These machines feature a single cylinder with one set of needles. They are ideal for producing lightweight fabrics such as T-shirts, underwear, and linings. Their operating principle is straightforward, emphasizing high-speed production and efficiency.

Double Jersey Circular Knitting Machines

Double jersey machines use both a cylinder and a dial, allowing the creation of rib, interlock, and other double-faced fabrics. This design produces thicker, more elastic fabrics suitable for sweaters, sportswear, and technical textiles.

Jacquard Circular Knitting Machines

Jacquard machines integrate electronic needle selection systems, enabling complex patterns, logos, and textured designs. The operating principle relies on selective needle activation according to programmed patterns, offering versatility for decorative and specialized fabrics.

Open-Width Knitting Machines

Open-width knitting machines produce flat knitted fabrics instead of tubular ones. They are widely used for wide panels of fabric, including blankets, upholstery, and industrial textiles. The operating principle is similar to circular knitting, with needles forming loops in a flat configuration, allowing precise control over fabric width, stitch density, and texture.

Advantages of Circular Knitting Machine Operation

The operating principle of circular knitting machines offers several advantages:

- High Productivity: Continuous circular motion enables faster fabric production.

- Consistent Quality: Precise control of needles and yarn ensures uniform fabric structure.

- Design Flexibility: Easy adjustment of cams and electronic controls allows multiple fabric styles.

- Material Efficiency: Tubular knitting reduces cutting waste.

These advantages make circular knitting machines indispensable in modern textile factories.

Applications in the Textile Industry

Circular knitting machines are used across a wide range of textile applications, including:

- Apparel fabrics (T-shirts, sportswear, underwear)

- Home textiles (bedsheets, mattress covers)

- Technical textiles (medical, automotive, industrial fabrics)

Their versatility and efficiency support both mass production and specialized manufacturing needs.

Conclusion

The operating principle of a circular knitting machine is based on the precise coordination of needles, cams, yarn feeders, sinkers, and take-up systems working in continuous circular motion. This principle allows for high-speed, efficient, and flexible production of knitted fabrics that meet the diverse demands of today’s textile market.

By understanding how each component functions and how they interact during the knitting process, manufacturers can optimize machine performance, improve fabric quality, and reduce production costs. As technology continues to advance, modern circular knitting machines are becoming smarter, faster, and more adaptable—ensuring their central role in the future of textile manufacturing.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Supplier Website

Source: https://www.xmnyuanda.com/news/understanding-the-operating-principle-of-circular-knitting-machines.html