Valve Stem Sealing: The Key to Ensuring Valve Reliability

In the industrial field, valves are indispensable equipment, functioning like traffic controllers within piping systems to precisely control the flow of fluids. Among the core components of a valve, the valve stem carries the crucial task of driving the disc to open and close the valve. However, since the valve stem is a movable part, it also becomes the most likely location for external leakage in the valve. Therefore, the importance of valve stem sealing is self-evident, as it directly affects the valve's reliability and safety.

Principle and Materials of Valve Stem Sealing

So, how does valve stem sealing work? And which materials are relied upon to achieve this critical function? Let us now explore the principles and materials of valve stem sealing in depth.

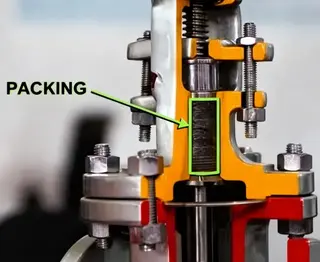

1. Compression Packing

Valve stem sealing is usually achieved through compression packing. Compression packing is a type of soft material that is pressed into the stuffing box to tightly wrap around the valve stem, thus preventing the medium from leaking. The working principle of packing is to apply pressure through the gland, allowing the packing to generate enough pressure on the transverse support surface to close the leakage channels, thereby achieving sealing. When the pressure direction transmitted by the packing aligns with that of the medium, the end-face pressure of the packing will generate equal pressure on the transverse support surface. This means that the lateral pressure received by the packing is usually higher than the medium pressure by the pressure applied through the gland, thus automatically creating a sealing effect.

2. Selection of Packing Materials

Among the many packing materials, asbestos fiber was once widely used as the base material. Asbestos has advantages such as high temperature resistance, corrosion resistance, and good thermal conductivity, and it is almost unaffected by most media, temperature, and time. However, the lubricating property of asbestos is relatively poor, so lubricants such as graphite powder and mica powder need to be added to improve its performance. In addition, since asbestos mixtures still have a certain degree of permeability, liquid lubricants must also be injected to further enhance the sealing effect.

With the advancement of technology, polytetrafluoroethylene (PTFE) has gradually become an ideal packing material. It has extremely low shrinkage and compression rates, a low friction coefficient, and excellent corrosion resistance to most corrosive media. The operating temperature range of PTFE packing is between -150℃ and 260℃. Within this range, it serves as a high-performance, multipurpose valve stem packing suitable for various industrial environments.

Flexible graphite is another high-performance packing material. It is not only resistant to high temperatures, with a working temperature up to 600℃, but also has a low friction coefficient and excellent corrosion resistance. Therefore, flexible graphite packing is widely used in valves operating under high-temperature conditions in power plants and petrochemical industries.

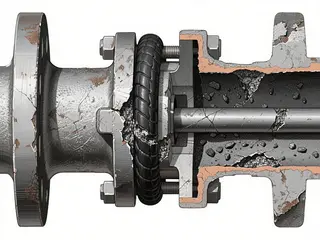

Corrosion and Protection of Valve Stem

As a key component of the valve, the corrosion of the valve stem has always been an important factor affecting both the service life and the sealing performance of the valve. Corrosion of the valve stem not only leads to leakage but may also cause more serious safety accidents. Therefore, understanding the causes of valve stem corrosion and taking effective protective measures is essential.

1. Corrosion Problem of Stainless Steel Valve Stem

Stainless steel valve stems, especially those made from chromium 13-series steel, are prone to corrosion on the surface in contact with packing. This type of corrosion often occurs during storage before use, especially after hydrostatic testing when the packing becomes saturated with water. Theoretically, the surface of a stainless steel valve stem in moist packing is in a deoxygenated environment, which affects the metal's activation and passivation characteristics. The oxygen-deficient points on the stainless steel oxide protective layer become small anodes, which, together with large areas of passive metal, form galvanic cells, thus accelerating corrosion. Graphite in the packing acts as an anode material, further increasing the galvanic current intensity and thereby accelerating the corrosion process.

2. Surface Treatment of Valve Stem

To improve the wear resistance and corrosion resistance of valve stems, surface treatments are usually applied. These treatments, including coating and plating, can effectively prevent leakage caused by stem bending, corrosion, and surface stress. The valve stem should have appropriate hardness and elasticity, be able to resist erosion and abrasion from the medium, and also possess excellent machinability. Through these measures, the valve stem can maintain good sealing performance under complex operating conditions.

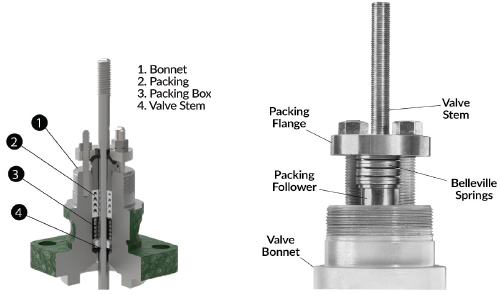

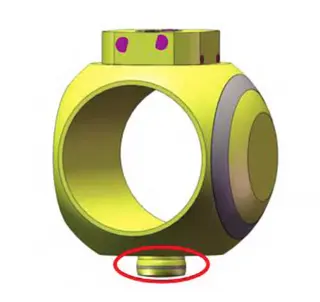

Structure of Valve Stem Sealing

Valve stem sealing mainly has two basic forms: rotary sealing and reciprocating sealing. Rotary sealing is suitable for valves in which the stem needs rotational movement, while reciprocating sealing is suitable for valves requiring linear back-and-forth stem motion. Different sealing forms should be selected based on the valve's specific working conditions and medium characteristics. Common sealing structures include externally compressed, internally compressed, and bidirectional compressed soft packing sealing structures.

1. Externally Compressed Soft Packing Sealing Structure

This sealing structure achieves sealing by compressing the packing externally with the gland. Under the axial force of the gland, radial contact pressure is generated between the soft packing and the valve stem. The advantage of this structure is that it is easy to manufacture, process, and maintain. However, the packing layer in contact with the medium receives the least radial pressure, which is not conducive to sealing. If the packing compression force is increased, sealing performance can be improved, but at the expense of higher stem operating torque and wear, ultimately reducing valve service life.

2. Internally Compressed Soft Packing Sealing Structure

The internally compressed soft packing sealing structure achieves sealing by pressing the packing from the inside through the gland. In this structure, the packing closest to the medium obtains the greatest radial contact force, and along the valve stem’s axial direction, the attenuation of radial pressure matches that of the medium pressure. As long as the radial contact pressure at each cross-section of the packing remains slightly greater than the medium pressure at that location, good sealing can be maintained. This structure is commonly used in high-pressure valves and, compared with the externally compressed type, requires less compression force, fewer packing rings, smaller stem operating torque, and less wear on both the stem and packing.

3. Bidirectional Compressed Soft Packing Sealing Structure

The bidirectional compressed soft packing sealing structure is equipped with two packing glands, upper and lower, which compress the packing from both the inner and outer sides to achieve sealing. Compared with the internal and external compression types, this structure allows a more uniform radial contact pressure distribution along the valve stem, ensuring each packing ring contributes to sealing. This forms an expansion–contraction-shaped leakage path, where the pressure drop at both ends of the path is significant, making sealing easier. Meanwhile, a thicker liquid film can form inside the leakage path, providing good lubrication, reducing packing wear on the valve stem, and extending valve service life.

Optimization and Maintenance of Valve Stem Sealing

Selecting the appropriate sealing form and structure is crucial for ensuring valve reliability and sealing performance. However, even the most advanced sealing designs must be optimized and maintained to achieve the best performance.

1. Design Optimization of Valve Stem Sealing

To improve the performance of valve stem sealing, optimization can be made in the following aspects:

Selection and Combination of Packing: Choose suitable packing materials based on the working medium, temperature, and pressure conditions, and combine them rationally. For example, in high-temperature and high-pressure environments, a combination of flexible graphite and PTFE packing can be used to maximize their respective advantages.

Stuffing Box Structure Design: Optimize the dimensions and shape of the stuffing box to ensure uniform pressure distribution on the packing, reducing stress concentration. Meanwhile, design the stuffing box depth and the number of packing rings appropriately to enhance sealing effectiveness.

Valve Stem Surface Treatment: Use advanced surface treatment technologies such as coating or plating to improve the valve stem's wear and corrosion resistance. In addition, optimizing the surface roughness of the valve stem can enhance contact between the packing and stem, improving sealing performance.

2. Maintenance & Care of Valve Stem Sealing

Maintenance and care of valve stem sealing are essential for the valve's long-term stable operation. The following are some maintenance recommendations:

Regular Inspection and Replacement of Packing: Regularly inspect the wear condition of the packing and replace any severely worn packing in time. During replacement, strictly follow operational procedures to ensure correct installation and proper compression.

Lubrication and Cleaning: Regularly lubricate and clean the valve stem and packing to prevent wear and corrosion caused by impurity accumulation. When lubricating, select appropriate lubricating oil or grease to avoid adverse effects on the packing and valve stem.

Monitoring and Adjustment: During valve operation, closely monitor the valve stem sealing for leakage. If leakage increases, adjust the gland compression force in time to maintain sealing. Also, avoid over-compression of the packing to prevent hindering stem movement and shortening service life.

Case Analysis

Next, let us analyze several practical cases to explore the challenges and solutions of valve stem sealing in different application scenarios.

1. Solution to a Valve Leakage Problem in a Chemical Plant

During production in a chemical plant, a valve used for conveying corrosive media experienced valve stem leakage. Inspection revealed that the valve adopted an externally compressed soft packing sealing structure, but due to insufficient gland compression force, the sealing between the packing and the stem was poor. Additionally, the valve stem surface showed signs of corrosion.

To solve this problem, technicians first performed surface treatment on the valve stem using a new anti-corrosion coating technology to enhance corrosion resistance. Next, they replaced the packing with a combination of PTFE and flexible graphite and redesigned the stuffing box structure by increasing the number of packing rings and optimizing the stress distribution. Finally, they adjusted the gland compression force to ensure uniform pressure on the packing, achieving an effective seal.

Through these improvements, the valve stem leakage problem was effectively resolved, and the valve's service life was significantly extended. This case fully demonstrates the importance of reasonable material selection, structural optimization, and enhanced surface treatment in improving valve stem sealing performance.

2. Sealing Optimization of a High-Temperature Valve in a Power Plant

In a power plant's high-temperature piping system, a valve used to control high-temperature steam frequently experienced valve stem sealing failure. Due to the high operating temperature, traditional asbestos packing could no longer meet sealing requirements, and although flexible graphite offered excellent heat resistance, the uneven pressure distribution between the packing and stem caused unstable sealing performance in practice.

To address this issue, engineers adopted a bidirectional compressed soft packing sealing structure using flexible graphite as the packing material. By setting upper and lower glands to compress the packing from both internal and external sides, the radial contact pressure between the packing and valve stem became more evenly distributed along the axial direction. At the same time, they optimized the stuffing box design and added lubrication measures to further improve sealing performance.

After these improvements, the valve's stem sealing performance was significantly enhanced, the steam leakage problem was effectively controlled, and the operational stability of the valve increased greatly, ensuring the safe and reliable operation of the power plant.

Conclusion

Valve stem sealing is a key aspect of reliable valve operation, directly affecting the sealing performance and service life of the valve. By selecting suitable packing materials, optimizing sealing structures, enhancing stem surface treatment, and performing proper maintenance, the performance of valve stem sealing can be effectively improved, ensuring stable valve operation under various complex conditions. In practical applications, the sealing scheme should be determined comprehensively based on specific operating conditions and medium characteristics to achieve the best valve performance.

Send your message to this supplier

Related Articles from the Supplier

How to Solve Common Problems of Valve Stem Packing?

- Nov 10, 2025

The Ultimate Guide to Installing Valve Packing

- Aug 02, 2025

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Supplier Website

Source: https://www.magpievalves.com/media-hub/valve-stem-sealing-the-key-to-ensuring-valve-reliability.html