Gasket Selection: Comparing Metallic and Non-Metallic Gaskets

In today's industrial field, whether it is large-scale oil pipelines, precision machinery assembly, or everyday pipeline connections, gaskets play a key role. They act as the "guardians" between connecting components, ensuring that all surfaces fit tightly together, preventing liquid or gas leaks, and extending the service life of equipment. Next, we will discuss the types of gaskets, material selection, and how to choose the most suitable gasket according to specific requirements.

Basic Function and Importance of Gaskets

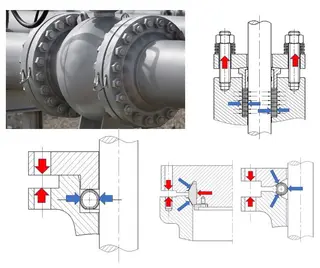

The main function of a gasket is to fill the space or gap between two or more mating surfaces. Do not underestimate this thin piece; it not only "fills the gap" but more importantly prevents liquid or gas from leaking at the joint under compression. For example, in oil pipelines, without a suitable gasket, oil may leak from the pipeline connection, not only wasting resources but also potentially causing serious safety accidents. In addition, gaskets can withstand high compressive loads, which is particularly important in high-pressure environments, ensuring the service life of the connected components.

Metallic Gaskets Overview

Metallic gaskets are made of a single metal or alloy. Compared to non-metallic gaskets, metallic gaskets provide higher quality surface sealing due to their material characteristics. They can resist extreme temperatures, pressure, and chemical corrosion, making them commonly used in medium- and high-pressure applications, especially performing exceptionally well in high-temperature environments.

1. Types of Metallic Gaskets

Ring-Type Joint (RTJ) Gaskets: These gaskets have a solid metal ring structure, with cross-sections in oval, circular, and octagonal shapes. RTJ gaskets have a channel hole that balances pressure on both sides of the surface seal, making them excellent for high-pressure applications.

Groove Gaskets: Designed to better fit the grooves of pipelines or equipment, ensuring a good sealing effect.

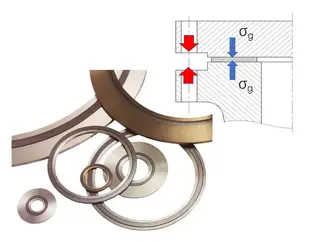

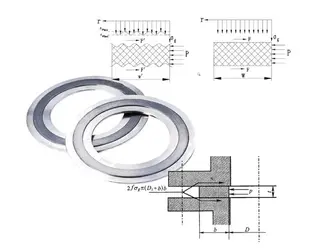

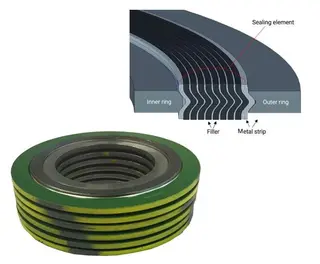

Spiral Wound Gaskets: Made by alternately winding metallic and non-metallic materials, combining the strength of metallic with the flexibility of non-metallic, suitable for various working conditions.

Corrugated Metallic Gaskets: With a corrugated structure, increasing the gasket's elasticity, it can better adapt to pressure changes.

Metallic Jacketed Gaskets: With a non-metallic core wrapped in a metallic jacket, combining the advantages of both materials.

2. Common Metallic Gasket Materials and Properties

Carbon Steel: Recommended maximum working temperature ≤538℃, especially in oxidative media. Not suitable for equipment in inorganic acids, neutral or acidic salt solutions, and prone to accidents under hot water conditions. Typically used for high-concentration acid and alkali solutions.

SS 304 Stainless Steel: 18-8 type, Cr content 18–20%, Ni 8–10%. Recommended maximum working temperature ≤760℃, prone to stress corrosion and intergranular corrosion in the -196℃ to 538℃ range.

SS 304L Stainless Steel: Carbon content ≤0.03%, corrosion resistance similar to 304 stainless steel. Low carbon content reduces carbon precipitation from the lattice, improving intergranular corrosion resistance.

SS 316 Stainless Steel: 18-12 type, Cr 18%, Ni 12%. Molybdenum added to 304 stainless steel improves strength and corrosion resistance. Recommended maximum working temperature ≤760℃.

SS 316L Stainless Steel: Recommended maximum continuous working temperature ≤760–815℃, with excellent stress and intergranular corrosion resistance.

Alloy 20: Contains 45% Fe, 24% Ni, 20% Cr, with small amounts of Mo and Cu. Recommended maximum working temperature ≤760–815℃, particularly suitable for equipment resistant to sulfuric acid corrosion.

Aluminum: Content not less than 99%, excellent corrosion resistance and machinability, suitable for manufacturing double-clad gaskets. Recommended maximum continuous working temperature ≤426℃.

Copper: Close to pure copper, with trace silver to improve corrosion resistance. Recommended maximum continuous working temperature ≤260℃.

Brass: Cu 66%, Zn 34%. Good corrosion resistance under most conditions, but not suitable for acetic acid, ammonia, salt, and acetylene. Recommended maximum continuous working temperature ≤260℃.

Hastelloy B-2: Contains 26–30% Mo, 62% Ni, 4–6% Fe. Recommended maximum working temperature ≤1093℃, excellent resistance to hot concentrated hydrochloric acid.

Hastelloy C-276: Contains 16–18% Mo, 13–17.5% Cr, 3.7–5.3% W, 4.5–7% Fe, the rest Ni. Recommended maximum working temperature ≤1093℃, excellent corrosion resistance to various concentrations of cold or boiling nitric acid.

Inconel 600: Nickel-based alloy, contains 77% Ni, 15% Cr, 7% Fe. Recommended maximum working temperature ≤1093℃, high strength at high temperature, suitable for equipment addressing stress corrosion issues.

Monel 400: Contains 30% Cu, high Ni content. Recommended maximum continuous working temperature ≤815℃, excellent corrosion resistance to most acids and alkalis except strong oxidizing acids. Prone to stress corrosion cracking in hydrofluoric acid, mercuric chloride, or mercury media; not suitable for these media.

Titanium: Recommended maximum working temperature ≤1093℃, excellent corrosion resistance at high temperatures, especially against chloride ion attack. Good corrosion resistance to nitric acid across a wide range of temperatures and concentrations. Rarely used in most alkaline solutions; suitable for oxidizing conditions.

3. Applications of Metallic Gaskets

Metallic gaskets are commonly used in offshore oil and gas pipelines, where high requirements for pressure and temperature resistance exist. In addition, they are widely used in heat exchangers, compressors, pumps, manholes, valves, and turbines, ensuring sealing performance and reliability under harsh conditions.

Non-Metallic Gaskets Introduction

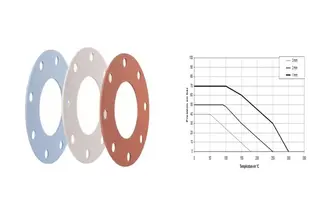

Non-metallic gaskets are made from composite materials such as fiberglass, mica sheets, ceramic fiber, elastomeric and fiber sheets, and compressed non-asbestos sheets. Compared with metallic gaskets, one major advantage of non-metallic gaskets is their excellent corrosion resistance. They can be easily compressed under bolt loads, but require operation under relatively low temperature and pressure.

1. Types of Non-Metallic Gaskets

Flat Gaskets: Suitable for flat flange connections, providing good sealing performance.

Flat Ring Gaskets: Suitable for raised-face flanges, fitting tightly to prevent leakage.

2. Common Non-Metallic Gasket Materials and Properties

Natural Rubber (NR): Good corrosion resistance to weak acids, alkalis, salts, and chloride solutions; poor resistance to oils and solvents. Recommended working temperature range: -57℃ to 93℃.

Chloroprene Rubber (CR): Resistant to moderate corrosion by acids, alkalis, and salts; good resistance to commercial oils and fuels, but poor resistance to strong oxidizing acids, aromatic hydrocarbons, and chlorinated hydrocarbons. Recommended working temperature: -51℃ to 121℃.

Nitrile Rubber (NBR): Good resistance to oils, solvents, aromatic hydrocarbons, alkaline hydrocarbons, petroleum, and natural gas over a wide temperature range; poor resistance to strong oxidizers, chlorinated hydrocarbons, ketones, and fats. Recommended working temperature: 51℃ to 121℃.

Fluororubber (FKM): Excellent heat and chemical resistance, good physical and mechanical properties. Outstanding heat resistance (200–250℃) and good oil resistance. Recommended working temperature: -40℃ to 232℃.

Chlorosulfonated Polyethylene (CSM): Good corrosion resistance to acids, alkalis, and salts; not affected by climate, light, ozone, or commercial fuels. Not suitable for aromatic hydrocarbons, chlorinated hydrocarbons, chromic acid, and nitric acid. Recommended working temperature: -45℃ to 135℃.

Silicone Rubber (SI): Outstanding high/low temperature performance, can be used long-term at 150℃, even continuously at 200℃ for 10,000 hours. Maintains elasticity in -70–260℃ range; suitable for thermal mechanism sealing gaskets. Special silicone rubbers can be used for oil seals.

EPDM: Good resistance to strong acids, strong alkalis, salts, and chlorides; not suitable for oils, solvents, aromatics, and hydrocarbons. Recommended working temperature: -57℃ to 176℃.

Graphite: Full graphite material has excellent resistance to many acids, alkalis, salts, and organic compounds; suitable for pipe gaskets over 600mm in diameter, but caution in high-temperature and strong oxidizing media.

Ceramic Fiber: Suitable for high-temperature, low-pressure conditions; recommended working temperature: 1093℃.

PTFE: Excellent temperature resistance (-95℃ to 232℃) and chemical resistance; resistant to most chemicals and solvents except free fluorine and alkali metals. Glass fiber can be added to reduce cold flow and creep.

3. Applications of Non-Metallic Gaskets

Non-metallic gaskets are usually used in low-pressure applications such as pipeline flanges, compressors, heat exchangers, and valve covers. In these applications, they provide reliable sealing while reducing equipment weight and manufacturing costs.

How to Choose Gaskets According to Operating Conditions

Choosing the right gasket is crucial to ensuring the safe operation and sealing performance of equipment. Gasket selection requires consideration of material properties along with actual operating conditions, including temperature, pressure, medium type, and cost.

Determine Operating Temperature: Temperature is a key factor. Different materials perform best within specific temperature ranges. For example, natural rubber (NR) is suitable for -57℃ to 93℃, while fluororubber can operate in the wider range of -40℃ to 232℃. Metallic gaskets are suitable for higher temperatures; carbon steel ≤538℃, while Hastelloy and titanium can operate up to 1093℃.

Determine Operating Pressure: Pressure is also important. Metallic gaskets are used in high-pressure applications like offshore oil and gas pipelines, while non-metallic gaskets are better suited for low-pressure environments. Spiral wound and metallic-jacketed gaskets withstand higher pressures, whereas natural rubber and EPDM suit low-pressure conditions.

Determine Medium Type: The medium is the liquid or gas the gasket contacts. Different media require different corrosion resistance. NBR resists oil, solvents, aromatics, alkaline hydrocarbons, petroleum, and natural gas but poorly resists strong oxidizers, chlorinated hydrocarbons, ketones, and fats. Graphite and PTFE resist a wide range of chemicals.

Consider Cost and Maintenance: Besides temperature, pressure, and medium, cost and maintenance are also factors. Metallic gaskets are usually more expensive but have longer life and lower maintenance. Non-metallic gaskets are cheaper but may need more frequent replacement. For example, graphite gaskets have excellent corrosion resistance but may need frequent replacement under high-temperature and strongly oxidizing conditions.

Conclusion

Gasket selection is a complex but critical process. By thoroughly understanding the properties of different materials and their performance under specific conditions, the most suitable gasket can be chosen for various industrial applications. Whether it is the high strength and high-temperature performance of metallic gaskets, or the corrosion resistance and compressibility of non-metallic gaskets, each material has unique advantages. This article aims to help you better understand the gasket selection process, ensuring your equipment operates safely and reliably under all conditions.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Essential Factors in Metal Gasket Selection

- Apr 08, 2024

Guide to Spiral Wound Gasket Selection

- Nov 07, 2025

Gasket Types & Selection for Industrial Flanges

- Mar 20, 2025

Materials of Flange Gaskets and Selection Guidelines

- Apr 10, 2025

Standards and Selection of Gaskets

- Mar 09, 2025

Related Products Mentioned in the Article

Supplier Website

Source: https://www.magpievalves.com/media-hub/gasket-selection-comparing-metallic-and-non-metallic-gaskets.html