Understanding Equal and Reducing Tees in Pipeline Engineering

In pipeline engineering, equal tees and reducing tees serve as essential pipe fittings, playing crucial roles in connecting different pipes and facilitating fluid transmission. This article provides a detailed introduction to these two types of pipe tees, covering their definitions, visual characteristics, applications, as well as maintenance and replacement procedures, aiming to help readers better understand and select the appropriate pipe fittings for their needs.

Definition and Visual Characteristics

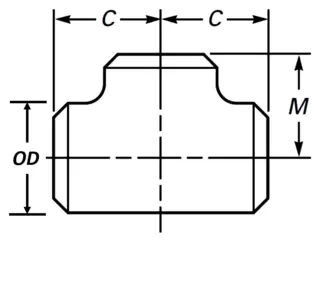

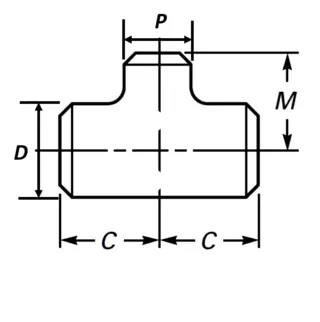

An equal tee refers to a tee fitting where the diameters of three connected pipes are equal, with the diameters of two branch pipes being equal to that of the main pipe. This type of tee is primarily used for the transmission of gases and liquids, such as water pipes, gas pipes, and oil pipelines. Equal tees typically exhibit a symmetrical appearance, ensuring balanced and stable pipe connections.

On the other hand, a reducing tee, formerly known as an unequal tee, is a tee fitting where the diameters of the three connected pipes are different, with the diameter of the main pipe differing from those of the two branch pipes. It is mainly employed to connect pipes of varying diameters, particularly when joining two pipes with different diameters. Reducing tees often display an asymmetrical appearance, with one branch pipe typically larger or smaller than the other branch pipe or the main pipe diameter.

Applications

Equal tees find extensive use in various industrial applications, especially in industries such as petroleum, chemical, and pharmaceuticals. These industries require the conveyance of large volumes of liquid or gas, and equal tees provide stable fluid flow while withstanding high pressures. Moreover, equal tees are easy to install and maintain, requiring minimal alteration to the pipeline.

Reducing tees are primarily utilized for connecting pipes of different diameters, commonly found in construction, municipal engineering, and similar fields. In such applications, there is often a need to connect pipes of dissimilar diameters to facilitate fluid transmission. Reducing tees fulfill this requirement while ensuring stable fluid flow.

Maintenance and Replacement

The maintenance and replacement procedures for equal tees and reducing tees differ slightly. Since the diameters of equal tees are identical, replacing or repairing them only requires purchasing tees of the same diameter. In contrast, reducing tees feature varying diameters, necessitating the purchase of tees matching the original pipe diameters. Therefore, extra care is required to ensure the selection of appropriate specifications during maintenance and replacement.

In conclusion, equal tees and reducing tees possess distinct characteristics and advantages in pipe connections. When selecting the appropriate type of tee fitting, it is essential to consider the specific requirements and operating environments. Therefore, understanding and correctly selecting suitable pipe fittings are vital for ensuring the smooth operation of pipeline systems.

Send your message to this supplier

Related Articles from the Supplier

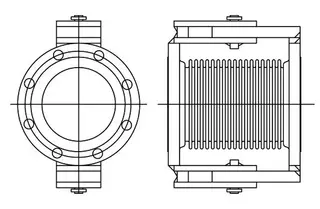

Understanding Expansion Joints in Pipelines

- Apr 01, 2024

Related Articles from China Manufacturers

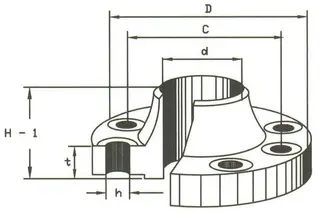

Related Products Mentioned in the Article

Supplier Website

Source: https://www.landeepipefitting.com/understanding-equal-and-reducing-tees-in-pipeline-engineering.html