Root Cause Analysis of Microstructural Abnormalities and Low Hardness in a P91 Elbow

Abstract

This study investigates abnormally high local hardness and metallographic microstructure observed in a high-temperature reheat steam pipeline elbow fabricated from SA335 P91 steel in a power plant. The chemical composition, wall thickness, hardness, and microstructure of the elbow were examined by spectral analysis, wall thickness measurement, hardness testing, and metallographic analysis, respectively. The causes of the abnormal hardness and microstructural characteristics were analyzed and discussed. The results indicate that the observed abnormalities were primarily caused by an improper heat treatment process during elbow manufacturing. Based on these findings, safety assessment measures incorporating strength verification are proposed to ensure the long-term safe and stable operation of the unit.

Introduction

SA335 P91 steel pipes are widely used in the manufacture of high-temperature and high-pressure steam pipelines and fittings for large thermal power generation units. This material exhibits excellent resistance to oxidation and high-temperature steam corrosion, as well as good impact toughness, stable long-term creep properties, and high thermal strength. However, if proper procedures are not strictly followed during the manufacturing, installation, or repair of pipe fittings, issues such as reduced hardness and abnormal metallographic structures may occur. During a Class C overhaul of a gas turbine combined-cycle power generation unit, abnormal hardness and microstructural characteristics were identified in a hot-section elbow of a high-temperature reheat steam pipeline made of SA335 P91 steel. The measured local hardness was below the minimum allowable value of 180 HBW specified in DL/T 438—2023, Technical Supervision Regulations for Metals in Thermal Power Plants. The observed microstructure consisted primarily of ferrite and bainite, indicating that both the mechanical properties and microstructure no longer met the applicable standard requirements, and replacement of the elbow would normally be required. However, replacement of such components is costly and economically unfavorable. Therefore, this study provides a technical reference for the analysis and handling of similar issues by conducting spectral analysis, Leeb hardness testing, Brinell hardness testing, metallographic examination, wall thickness measurement, and strength verification on the affected elbow.

1. Elbow Inspection and Analysis

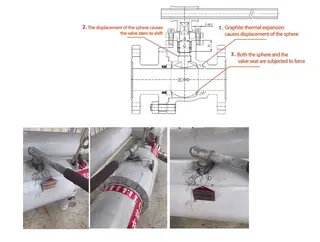

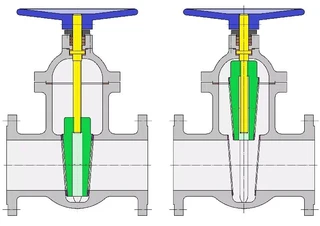

The high-temperature reheat steam pipeline elbow is shown in Figure 1, and the inspection locations on the elbow are illustrated in Figure 2.

1.1 Spectral Analysis

After grinding the outer back-arc surface of the high-temperature reheat steam pipeline elbow (W2) to expose a clean metallic surface, semi-quantitative spectral analysis was carried out. The results showed that the contents of the main alloying elements—Cr, Mo, Mn, and V—were 9.0 wt.%, 1.0 wt.%, 0.5 wt.%, and 0.2 wt.%, respectively. These values generally satisfy the compositional requirements specified for SA335 P91 steel, and no compositional abnormalities were identified.

1.2 Leeb Hardness Testing

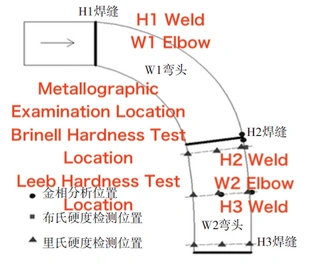

Leeb hardness tests were conducted on three cross-sections of the high-temperature reheat steam pipeline elbow W2: the section near the upper H2 weld (#1), the middle section (#2), and the section near the lower H3 weld (#3). At each cross-section, four measurement points were selected at angular positions of 0°, 90°, 180°, and 270°, measured counterclockwise from the back-arc surface along the medium flow direction. The test results are summarized in Table 1.

As shown in Table 1, the hardness values at each measurement location exhibit good repeatability. Based on the average hardness values at each measuring point, a hardness distribution curve was plotted, as shown in Figure 3. The results indicate that the hardness measured at the 0° direction (back-arc surface) is below the lower limit of 180 HBW specified by the applicable standard, whereas the hardness measured at the 180° direction (inner-arc surface) meets the standard technical requirements. Overall, the hardness values show a gradual increase from the back-arc surface toward the inner-arc surface.

Figure 1 High-Temperature Reheat Steam Pipeline Elbow

Figure 2 Schematic Diagram of Test Locations on the High-Temperature Reheat Steam Pipeline Elbow

Figure 3 Leeb Hardness Test Results

1.3 Brinell Hardness Test

After grinding the back-arc surface of the high-temperature reheat steam pipeline elbow W2 (near weld H2, where the lowest Leeb hardness was recorded), an on-site Brinell hardness verification test was performed. The test results showed an average Brinell hardness of 169 HBW. This value is also lower than the specified lower limit but is significantly higher than the corresponding Leeb hardness measurement. Leeb hardness testing is known to be influenced by factors such as specimen mass and thickness, impact direction, and surface roughness, which may introduce considerable measurement error. Therefore, DL/T 438—2023 recommends that when abnormal results are identified in Leeb hardness testing, Brinell hardness testing should be used for verification.

1.4 Metallographic Analysis

Metallographic examinations were conducted on the back-arc surface and neutral surface of the high-temperature reheat steam pipeline elbow W2, as well as on the back-arc surface of elbow W1. The material removal depth for metallographic preparation was approximately 1 mm. The metallographic structure of the back-arc surface at the middle section of elbow W2 consists of ferrite + bainite + carbides, as shown in Figure 4(a). The neutral surface at the middle section of elbow W2 exhibits a microstructure of tempered martensite + bainite, with an aging grade of level 3, as shown in Figure 4(b). The microstructure of the base metal near weld H2 on the back-arc surface of elbow W2 is also ferrite + bainite + carbides, as shown in Figure 4(c). In contrast, the microstructure of the base metal near weld H2 on the back-arc surface of elbow W1 (sampling position #4) is tempered martensite, with an aging grade of approximately 2.5, as shown in Figure 4(d). According to DL/T 438—2023, the δ-ferrite content in 9%–12% Cr series steel pipes and fittings shall not exceed 5%. However, as observed in Figures 4(a) and 4(c), the δ-ferrite content in elbow W2 is approximately 30%–40%, indicating a significantly abnormal microstructure.

Figure 4 Metallographic Structures of the Elbows

(a) Back-arc surface of the middle section of elbow W2 (500×) (b) Neutral surface of the middle section of elbow W2 (500×)

(c) Back-arc surface of elbow W2 near weld H2 (500×) (d) Back-arc surface of elbow W1 near weld H2 (500×)

Table 1 Leeb Hardness Test Results

|

Test Location |

Test 1 |

Test 2 |

Test 3 |

Test 4 |

Test 5 |

Average Value |

|

#1 Cross Section |

|

|

|

|

|

|

|

0° Position (Back-Arc Surface) |

155 |

155 |

152 |

146 |

146 |

151 |

|

90° Position (Neutral Surface) |

185 |

180 |

177 |

179 |

180 |

180 |

|

180° Position (Inner-Arc Surface) |

199 |

198 |

201 |

194 |

194 |

197 |

|

270° Position (Neutral Surface) |

182 |

180 |

181 |

182 |

179 |

181 |

|

#2 Cross Section |

|

|

|

|

|

|

|

0° Position (Back-Arc Surface) |

159 |

163 |

161 |

160 |

159 |

160 |

|

90° Position (Neutral Surface) |

168 |

175 |

170 |

172 |

169 |

171 |

|

180° Position (Inner-Arc Surface) |

201 |

199 |

198 |

199 |

201 |

200 |

|

270° Position (Neutral Surface) |

192 |

192 |

194 |

196 |

190 |

193 |

|

#3 Cross Section |

|

|

|

|

|

|

|

0° Position (Back-Arc Surface) |

156 |

164 |

154 |

167 |

163 |

161 |

|

90° Position (Neutral Surface) |

192 |

194 |

192 |

190 |

193 |

192 |

|

180° Position (Inner-Arc Surface) |

195 |

197 |

200 |

196 |

197 |

197 |

|

270° Position (Neutral Surface) |

193 |

200 |

195 |

197 |

192 |

195 |

1.5 Wall Thickness Measurement

For the high-temperature reheat steam pipeline elbow W2, ultrasonic wall thickness measurements were conducted at four circumferential locations (0°, 90°, 180°, and 270°) on three representative cross-sections: the cross-section near weld H2 (#1), the middle cross-section of the elbow (#2), and the cross-section near weld H3 (#3). Measurements were taken counterclockwise from the back-arc surface along the direction of medium flow. The results indicate that the wall thickness at the back-arc surface of elbow W2 near welds H2 and H3 is relatively thin, with a minimum measured wall thickness of 22.62 mm. The detailed measurement results are summarized in Table 2.

Table 2 Wall Thickness Measurement Results

Unit: mm

|

Measurement Position |

0° |

90° |

180° |

270° |

|

#1 Cross Section |

22.62 |

25.30 |

25.67 |

26.64 |

|

#2 Cross Section |

28.28 |

27.96 |

27.10 |

28.68 |

|

#3 Cross Section |

27.06 |

23.34 |

25.70 |

27.91 |

2. Analysis of the Causes of Local Microstructural Abnormalities in the Elbow

Based on a comprehensive evaluation of the metallographic examination and hardness test results, the direct cause of the low hardness observed in the high-temperature reheat steam pipeline elbow W2 is identified as an abnormal microstructure on the back-arc surface. The microstructure in this region is primarily composed of ferrite, bainite, and carbides, rather than the normal tempered martensitic structure expected for SA335 P91 steel. According to the corresponding domestic grade 10Cr9Mo1VNbN, GB/T 5310—2023 Seamless Steel Tubes for High-Pressure Boilers (Clause 7) specifies an upper allowable service temperature of 620 °C for this material, which is significantly higher than the pipeline design temperature of 571 °C. Therefore, material overheating during service can be excluded as a contributing factor.

Metallographic observations show that the adjacent elbow W1, which is connected to elbow W2, exhibits a tempered martensitic structure with an aging grade of 2.5. This indicates that P91 steel is not susceptible to significant microstructural aging under the current operating conditions of the unit. Moreover, microstructural aging caused by long-term exposure to elevated temperature and stress is typically characterized by martensite lath coarsening and carbide redistribution. In contrast, a large amount of blocky ferrite is observed on the back-arc surface of elbow W2, suggesting that the local microstructural abnormality is unrelated to service conditions.

Generally, ferrite formation in P91 steel may be attributed to the following factors:

- Excessively high tempering temperature exceeding the Ac₁ phase transformation temperature, leading to ferrite formation.

- Ferrite formation during tempering as a result of recovery and recrystallization processes.

- For thick-walled components, excessively slow cooling during quenching or normalizing, resulting in premature ferrite formation.

In this case, the abnormal microstructure is predominantly localized on the back-arc surface of the elbow, while other regions exhibit normal microstructure and hardness. The ferrite content in the affected area is significantly higher than expected. This distribution indicates that the tempering temperature during manufacturing was excessively high, although the likelihood of exceeding the Ac₁ transformation temperature is relatively low. Similarly, if the cooling rate during heat treatment were excessively slow, the ferrite formed would be expected to appear primarily in the central region of the component. Under such conditions, the austenite transformation curve would enter the ferrite transformation region, resulting in limited ferrite formation at the core. This scenario is inconsistent with the actual metallographic observations.

Because the abnormal microstructure and localized softening are concentrated in the region of greatest deformation on the back-arc surface of the elbow, it is highly likely that the local microstructural abnormality was caused by recrystallization during tempering. The primary factors influencing recrystallization include the degree of plastic deformation and the stored deformation energy in the metal. Greater deformation results in higher stored energy, which provides a stronger driving force for recrystallization and allows it to occur at lower temperatures.

Although factors such as metal purity and initial grain size can also affect recrystallization behavior, metallographic analysis indicates that the grain size is uniform throughout the component, the chemical composition is homogeneous, and no significant differences in material purity are present. However, during the elbow bending process, the back-arc surface experiences substantial tensile plastic deformation, leading to a significantly higher recrystallization driving force during subsequent tempering. As a result, recrystallization preferentially occurs in these highly deformed regions, forming ferrite and causing localized softening on the back-arc surface of the elbow.

3. Elbow Strength Verification

Considering that the abnormality observed in the high-temperature reheat steam pipeline elbow W2 was determined to be unrelated to service operation, a safety assessment approach was adopted to evaluate the structural integrity of the elbow and determine appropriate handling measures. The elbow specifications and operating parameters are listed in Table 3. Strength verification was performed in accordance with GB/T 32270—2015, Pressure Piping Specifications—Power Piping.

Table 3 Elbow and Operating Parameters

|

Parameter |

Value |

|

Pipe specification |

Φ641 × 15 mm (OD 671 × 15 mm) |

|

Design pressure |

2.55 MPa |

|

Working pressure |

2.23 MPa |

|

Design temperature |

571 °C |

|

Working temperature |

564 °C |

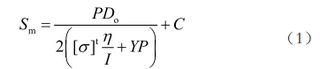

Wall Thickness Calculation Method

When the required wall thickness of the elbow is determined based on the outer diameter, the calculation is performed according to Equation (1). In this equation, σ represents the allowable stress of the material at the design temperature. For conservative evaluation under conditions of reduced hardness and abnormal metallographic structure, the allowable stress was taken as 38.3 MPa. This value corresponds to the allowable stress for the same material and operating conditions when the base metal hardness is 145 HB.

The remaining parameters are defined as follows:

n: allowable stress correction factor, 1.0

I: calculation factor, 1.0 at the elbow neutral line

Y: correction coefficient, 0.7

P: design pressure, 2.55 MPa

D: outer diameter, 671 mm

C: additional thickness allowance for corrosion, wear, and mechanical strength. For non–steam–water two-phase flow and non-corrosive media, CCC is taken as 0.

Based on Equation (1), the minimum required wall thickness at the neutral line is 21.34 mm.

For the outer arc of the bend or elbow, the thickness correction factor III is given by:

Here, R is the bending radius of the elbow (mm). This indicates that the minimum required wall thickness at the outer arc is smaller than that at the neutral line. Therefore, the controlling minimum wall thickness is that at the neutral line. The measured minimum wall thickness of elbow W2 is 22.62 mm, exceeding the calculated minimum required thickness under conservative assumptions that account for reduced hardness and metallographic abnormalities. Therefore, the strength of elbow W2 meets the design requirements, provided that the operating pressure and temperature remain within the specified design limits.

4. Conclusions

- A significant amount of ferrite, rather than the expected tempered martensitic structure, was observed on the back-arc surface of the SA335 P91 high-temperature reheat steam pipeline elbow. The hardness in this region was below the lower limit specified by the applicable standard, which is attributed to substantial plastic deformation of the back-arc surface during the elbow forming process. As the degree of deformation increases, both the stored deformation energy and the driving force for recrystallization increase. During subsequent tempering, recrystallization occurred preferentially in the highly deformed back-arc region, leading to ferrite formation and localized softening.

- Periodic monitoring of the elbow’s metallographic structure and hardness is recommended during service to prevent abnormal microstructural evolution and performance degradation. In addition, operating conditions should be strictly controlled to ensure that the pressure and temperature remain within allowable limits. Under these conditions, the strength of the elbow will not compromise safe operation. Additionally, acceptance inspection of newly procured elbow components should be reinforced. Under these conditions, the strength of the elbow will ensure safe operation. Furthermore, acceptance inspection of newly procured elbow components should be reinforced.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Supplier Website

Source: https://www.landeepipefitting.com/root-cause-analysis-of-microstructural-abnormalities-and-low-hardness-in-a-p91-elbow.html