Slab Gate Valves vs. Wedge Gate Valves: How to Choose

In industrial piping systems, gate valves are among the most commonly used control devices, primarily designed to shut off or allow the flow of media. Based on the structure of the gate, these valves are mainly divided into two categories: slab gate valves and wedge gate valves. Although their functions are similar, they differ significantly in structural design, sealing principles, and application scenarios. This article begins with fundamental concepts and provides an in-depth comparison of the technical characteristics of both gate valve types to help engineers and procurement professionals make informed decisions.

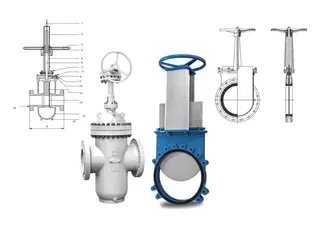

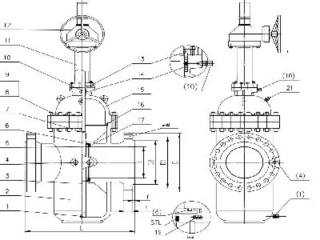

What is Slab Gate Valve?

The defining feature of a slab gate valve is that the gate is parallel to the pipeline’s vertical centerline. The gate has a flat, plate-like shape and moves vertically to open or close the valve. In slab gate valves equipped with a through-conduit port, a circular passage is machined into the gate so that when the valve is fully open, the port aligns with the pipeline to form a smooth, straight flow path.

The seating force is generated by medium pressure acting on either a floating gate or a floating seat. In double-gate designs, a spreading mechanism between the two gates supplements this seating force to ensure reliable sealing. This configuration allows the operating torque of a slab gate valve to be roughly half that of conventional gate valves, making operation easier.

1. Core Advantages of Slab Gate Valves

Bidirectional Sealing Capability: The valve seat incorporates an O-ring seal combined with a preloaded floating seat structure, enabling reliable sealing on both the inlet and outlet sides. Regardless of the flow direction, the valve can effectively shut off the medium, an important feature in applications where reverse pressure may occur.

Extremely Low Flow Resistance: When fully open, the through-conduit design creates a smooth, straight passage with minimal flow resistance and virtually no pressure loss. This characteristic significantly reduces pump energy consumption and improves transmission efficiency when transporting energy media such as crude oil and natural gas.

Pipeline Cleaning Compatibility: The through-conduit allows cleaning pigs to pass directly through the valve, eliminating the need for bypass lines during pipeline cleaning operations. This capability is particularly valuable in long-distance oil and gas pipelines, where it can greatly reduce maintenance downtime.

Zero-Leakage Sealing System: Slab gate valves employ a dual sealing mechanism that combines metal sealing surfaces, typically stainless steel or cobalt-chromium-tungsten hardfacing, with an emergency sealant injection system for absolute sealing under extreme conditions. The stuffing box is also equipped with an auxiliary sealant injection structure, addressing the common issue of external leakage found in traditional valve packing systems.

Safety-Oriented Design: When the valve is closed, internal cavity overpressure is automatically relieved, preventing safety incidents caused by improper operation. The fully enclosed structure offers excellent protection and is suitable for continuous outdoor service in all weather conditions.

2. Typical Applications of Slab Gate Valve

Slab gate valves are widely used in pipelines transporting petroleum, gasoline, natural gas, and other energy media, especially in the following situations:

Long-distance pipelines requiring regular pigging

Energy-efficient systems with strict flow resistance requirements

Applications demanding high-performance bidirectional sealing

Low-pressure systems requiring throttling or limited flow adjustment

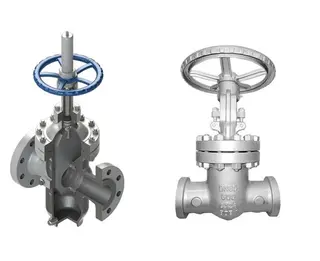

An Introduction to Wedge Gate Valves

The sealing surfaces of a wedge gate valve form an angle with the vertical centerline, creating a wedge shape. This angle, known as the wedge half-angle, commonly measures 2°52′ or 5°. Gates may be configured as solid (rigid), flexible, or double-disc types.

During closure, the valve stem rotates clockwise, driving the wedge downward. Leveraging the mechanical advantage of the wedge geometry, the sealing surfaces on both sides tightly contact the valve body seats, generating sealing pressure. The auxiliary load produced by this wedging action allows the valve to withstand high medium pressure while maintaining sealing performance even under low-pressure conditions.

1. Comparison of Three Gate Designs

Flexible Gate

A circumferential groove is machined along the vertical centerline of the single gate, providing slight elastic deformation capability. Upon closure, the gate flexes to compensate automatically for machining tolerances and dimensional deviations caused by temperature changes, ensuring full contact with both seats.

Advantages: Simple structure, reliable sealing, strong temperature adaptability, and relatively lower machining precision requirements.

Disadvantages: Not suitable for media containing solid particles, which may clog the groove and affect elasticity.

Typical Range: Small- and medium-diameter valves across various pressures and temperatures.

Solid (Rigid) Gate

This single-piece design offers no compensation capability and therefore demands extremely high machining accuracy for the wedge half-angle on both sealing surfaces. Changes in temperature or pipeline loads that affect seat alignment directly impact sealing performance, and the valve may seize under high temperatures.

Typical Range: Small valves (DN50 and below) in low-pressure applications with temperatures not exceeding 121°C.

Double-Disc Gate

Two discs are connected via a spherical pivot, allowing them to adjust their angle freely to match the seat. They are less prone to jamming during temperature fluctuations, and worn sealing surfaces can be compensated by adding shims.

Advantages: Self-adjusting angle, excellent temperature adaptability, and easy maintenance.

Disadvantages: More complex structure with additional components; unsuitable for viscous media; long-term corrosion may cause disc detachment.

Typical Range: Medium to large valves (DN50–600) with operating temperatures from -196°C to 816°C.

2. Unidirectional Sealing Characteristic

Metal-seated wedge gate valves exhibit an important trait: forced unidirectional sealing. Because the sealing pressure generated on the inlet side by the wedging action is often insufficient to counteract the medium pressure, the medium force may weaken the inlet seal. As a result, reliable sealing is typically achieved only on the outlet side, making it essential to follow the flow direction marking during installation.

3. Limitations of the Bottom Cavity

A cavity at the bottom of the valve body accommodates the descending gate. However, this structure allows solid deposits in the pipeline to accumulate in the cavity, and they cannot be removed by pigging. Therefore, wedge gate valves are not recommended for applications requiring frequent pipeline cleaning.

Key Performance Comparison

|

Comparison Item |

Slab Gate Valve |

Wedge Gate Valve |

|

Sealing Direction |

Bidirectional |

Primarily unidirectional |

|

Flow Resistance |

Extremely low (similar to straight pipe) |

Relatively higher |

|

Operating Torque |

About half that of conventional gate valves |

Requires greater closing force |

|

Pigging Capability |

Through-conduit types allow pig passage |

Bottom cavity prevents pigging |

|

Throttling Function |

Can provide limited regulation |

Typically for full open/close only |

|

Temperature Adaptability |

Moderate |

Flexible/double-disc types: -196°C to 816°C |

|

Machining Requirements |

High parallelism of sealing surfaces |

High wedge-angle precision |

|

Structural Complexity |

Relatively simple |

Double-disc types are more complex |

|

Suitable Media |

Clean fluids and media with suspended particles |

Oil, steam, high-temperature and high-pressure media |

|

Cost |

Higher (dual sealing surface machining is complex) |

Rigid types are more economical |

Selection Recommendations and Application Guidelines

Based on the structural principles and performance characteristics outlined above, both valve types present distinct strengths and limitations. The following guidance provides a systematic approach to valve selection from the perspectives of service conditions, media characteristics, and economic considerations.

1. When to Prioritize Slab Gate Valves

Long-distance transmission pipelines: Through-conduit slab gate valves are the only practical option for pipelines requiring routine pigging.

Energy-sensitive systems: Projects with limited pump head or high electricity costs benefit from the valve’s minimal flow resistance.

Bidirectional pressure requirements: In processes where reverse pressure may occur, bidirectional sealing simplifies system design.

Minor flow adjustment needs: While gate valves are not intended for regulation, slab gate valves can provide rough flow adjustment near the fully open position.

2. When to Prioritize Wedge Gate Valves

High-temperature and high-pressure conditions: Flexible and double-disc designs adapt well to severe temperature fluctuations and high differential pressure, such as main steam systems in power plants or high-pressure hydrotreating units.

Extremely high sealing reliability: The mechanical advantage of the wedge structure excels under high differential pressure, making it suitable for critical isolation points.

Space-constrained installations: Wedge gate valves are relatively compact and advantageous in pipe racks or equipment rooms with limited space.

Cost-sensitive small projects: Rigid wedge valves below DN50 offer excellent cost efficiency for standard low-pressure water lines and similar services.

3. Special Considerations

Clarifying the Throttling Function: Although slab gate valves can provide limited regulation, all gate valves are fundamentally designed for fully open or fully closed service. Systems requiring precise flow control should use globe valves or control valves rather than relying on partially open gate valves. Operating a gate in a half-open position exposes the sealing surfaces to erosion, accelerating wear and shortening service life.

Media Containing Solid Particles: The sliding sealing surfaces of slab gate valves can tolerate media with suspended particles to some extent, whereas wedge gate valves, especially flexible types, are sensitive to solids. For pipelines that may contain welding slag or rust, installing a strainer upstream is recommended.

Installation Direction Requirements: When installing a wedge gate valve, always follow the flow direction indicated on the valve body to ensure the medium enters from the seat-sealing side, allowing pressure to enhance the sealing effect. Reverse installation can result in sealing failure. Slab gate valves do not have this limitation.

Conclusion

Slab gate valves and wedge gate valves each offer irreplaceable technical advantages; neither is universally superior. Slab gate valves stand out for their low flow resistance, bidirectional sealing, and pigging convenience, making them the preferred choice for energy transmission pipelines. Wedge gate valves, with their simple structure, strong high-pressure adaptability, and cost advantages, continue to dominate traditional sectors such as petrochemical processing and power generation.

Proper valve selection should be based on specific operating parameters, including media characteristics (cleanliness and corrosiveness), pressure and temperature ratings, operating frequency, maintenance conditions, and budget constraints. Understanding the fundamental differences between these two valve types enables optimal engineering decisions and ensures the long-term safety and efficiency of pipeline systems.

In actual procurement, it is advisable to communicate process details thoroughly with professional valve manufacturers. When necessary, request type test reports and documented performance in comparable service conditions to verify the valve’s suitability for the intended application.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Slab Gate Valve VS Wedge Gate Valve

- Nov 29, 2022

Exploring the Versatility of Slab Gate Valves

- Dec 12, 2023

Related Products Mentioned in the Article

Supplier Website

Source: https://www.landee.cn/news/industry-news/slab-gate-valves-vs-wedge-gate-valves-how-to-choose.html