Resilient Seated Gate Valve: Reliable Choice for Fluid Control

In modern industrial production, fluid control is a crucial process. Whether in water supply and drainage systems, the petrochemical industry, or the food and pharmaceutical fields, reliable valves are needed to ensure safe and efficient fluid transmission. Resilient seated gate valves, as a high-performance valve product, have become the first choice in many industrial fields due to their unique design and excellent performance. This article provides a detailed introduction to the working principle, structural features, application scope, and maintenance of resilient seated gate valves, helping readers fully understand this efficient fluid control device.

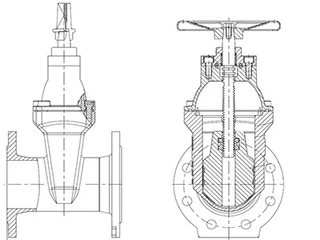

Overview of Resilient Seated Gate Valves

A resilient seated gate valve is a valve that uses the slight elastic deformation of the gate to achieve sealing. Its working principle is that the rotation of the valve stem nut causes the sealing surface of the gate to rub against the sealing surface of the valve seat, thereby opening and closing the valve. This type of valve has good sealing performance and corrosion resistance and is widely used in various fluid pipeline systems.

1. Working Pressure and Temperature Range

The working pressure of resilient seated gate valves is generally below 1.6 MPa, and the working temperature does not exceed 80°C. This pressure and temperature range allows it to adapt to most common industrial fluid environments, such as water supply and drainage systems, urban water supply networks, and industrial cooling water systems. In these applications, resilient seated gate valves can operate stably, ensuring the normal transmission of fluids.

2. Sealing Principle

The sealing pair of a resilient seated gate valve consists of a rubber-coated gate and an iron valve body sealing surface with surface electrostatic powder coating. The rubber covering the gate is made of 70A nitrile rubber, which has good elasticity and oil resistance, allowing it to produce significant elastic-plastic deformation under small sealing force, effectively filling the leakage gap. However, the allowable stress of rubber is relatively low. If excessive sealing force is applied, the rubber may be over-compressed, causing permanent deformation and loss of sealing capability. Therefore, it is essential to select an appropriate rubber compression rate and coordinate the structural parameters of the sealing pair.

Structural Features of Resilient Seated Gate Valves

The structural design of resilient seated gate valves is sophisticated, with multiple unique features that enhance sealing performance and service life.

1. Three-Dimensional Sealing Structure

The resilient seated wedge gate valve is a straight-through type, with no recess at the bottom of the valve body flow path. This design changes the traditional wedge gate valve's reliance solely on wedge face sealing. Three-dimensional sealing is achieved synchronously through: two 12°15′ wedge faces compressed forward and backward along the Z-axis, two 40° inclined faces compressed left and right along the X-axis, and an arched surface compressed downward along the Y-axis. This three-dimensional sealing structure effectively reduces wear on the sealing surfaces and distributes sealing force evenly in different directions, ensuring a reliable seal.

2. Wedge and Inclined Surface Design

The wedge faces on both sides move downward over a relatively long distance during sealing due to the wedge angle. To reduce wear on the rubber-coated wedge faces during movement, a larger wedge angle is usually chosen, or the wedge face is tilted slightly around the Y-axis, sequentially reducing the compression. The inclined surfaces are set at a 40° angle, closest to the arc surface direction, combining with the wedge face to complete the transition from wedge face to arc face sealing.

3. Sealing Surface Compression Rate and Hardness Selection

The compression rate of rubber seals is recommended to be 8%–40%, and the hardness of the rubber-coated gate is ideally 65–70A. By adjusting the structural parameters of the valve body and gate sealing surfaces, the compression rate and downward displacement of the rubber seals in all directions can be coordinated, achieving three-dimensional synchronous sealing with minimal closing torque. The tolerance for the valve body flow path radius and the large-end gap of the valve body wedge is preferably ±10 mm. Proper tolerance control ensures that the valve closing torque remains within a reasonable range, extending the service life of the rubber-coated gate.

4. Valve Stem Sealing Design

The valve stem uses a triple O-ring seal, greatly reducing friction during operation and enabling smooth, leak-free operation. At the same time, the valve body is precision cast, with accurate geometric dimensions ensuring valve sealing without further machining. This design not only improves sealing performance but also reduces production costs.

Applications of Resilient Seated Gate Valves

Due to their excellent performance and wide applicability, resilient seated gate valves are widely used in multiple industrial fields.

1. Water Supply and Drainage Systems

In water supply and drainage systems, resilient seated gate valves are ideal control devices. Their working pressure and temperature range meet the requirements of urban water supply networks and industrial drainage systems. The valve's reliable sealing effectively prevents leakage, ensuring efficient water resource utilization. In addition, the valve's corrosion resistance allows it to operate stably in sewage systems over long periods, resisting rust and aging.

2. Petrochemical Industry

The petrochemical industry requires high sealing performance and corrosion resistance. The nitrile rubber-coated gate of the resilient seated gate valve can withstand various chemical media, and the three-dimensional sealing structure ensures reliable sealing under high pressure and temperature. These valves are widely used in critical areas such as oil pipelines and chemical reactor inlets and outlets, effectively ensuring smooth petrochemical production.

3. Food and Pharmaceutical Industry

The food and pharmaceutical industry requires strict hygiene and safety standards. The valve body is coated with non-toxic epoxy, and the inner and outer surfaces of the gate are fully rubber-coated, preventing rust and corrosion and meeting food and pharmaceutical standards. These valves can be used in food processing lines and pharmaceutical equipment to ensure fluid purity and safety.

4. Other Industrial Fields

Resilient seated gate valves are also widely used in textiles, power, shipbuilding, metallurgy, and energy systems. Their structural versatility allows selection of single or double wedge gates and various connection types, such as flanged or wafer-style, to meet different working conditions. This adaptability enables resilient seated gate valves to satisfy complex industrial requirements.

Maintenance of Resilient Seated Gate Valves

Regular maintenance is essential to ensure long-term stable operation.

1. Regular Inspection

Check the valve's sealing performance and mechanical component wear regularly. Inspect the rubber coating on the gate for aging, cracking, or peeling, ensure the valve stem O-ring seals are intact, and check the valve body for corrosion or damage. Repair or replace components promptly if issues are found.

2. Cleaning and Lubrication

Regularly clean internal and external dirt and debris to prevent accumulation from affecting sealing performance. Lubricate the valve stem and other moving parts to reduce friction and extend service life. Use appropriate cleaning agents and lubricants to avoid damaging valve materials.

3. Operational Standards

Follow correct operation procedures when using resilient seated gate valves. Avoid excessive force during operation to prevent damage to the rubber sealing surface or valve stem seals. Apply pressure slowly when closing to ensure uniform sealing surface load and avoid local overloading. Regularly check closing torque to ensure it remains within a reasonable range.

4. Environmental Adaptability

Although resilient seated gate valves have good corrosion resistance and adaptability, appropriate protective measures should be taken in harsh environments. For outdoor installations, consider rain, sun, and frost protection to prevent environmental damage. Avoid external impacts during installation and operation to protect the valve structure.

Advantages of Resilient Seated Gate Valves

Excellent Sealing Performance: Three-dimensional sealing structure and optimized rubber compression achieve reliable sealing even under high pressure and temperature, reducing fluid leakage, energy waste, and environmental pollution.

Strong Corrosion Resistance: Non-toxic epoxy-coated bodies and fully rubber-coated gates effectively prevent corrosion and rust, ensuring long-term stable operation in harsh chemical environments.

Easy Operation: Triple O-ring stem design reduces friction, making operation smooth and leak-free, improving convenience and reducing labor intensity.

Compact Structure: Compact, lightweight design facilitates installation and maintenance, especially in space-limited scenarios, while reducing installation and maintenance costs.

Long Service Life: Reasonable structural design and material selection, with elastic memory of the rubber coating and precision casting of the valve body, significantly enhance durability. With proper use and maintenance, resilient seated gate valves can operate stably over long periods.

Conclusion

As a high-efficiency, reliable fluid control device, resilient seated gate valves play an important role in the industrial field. Their excellent sealing performance, corrosion resistance, ease of operation, and long service life make them a top choice for many industrial users. Through proper maintenance and ongoing innovation, resilient seated gate valves will continue to provide reliable solutions for industrial fluid control in the future.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Pros and Cons of Resilient Seated Gate Valves

- Apr 10, 2024

What are Resilient-seated Gate Valves?

- Aug 22, 2025

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/resilient-seated-gate-valve-reliable-choice-for-fluid-control.html