Optimizing Metal-Seated Ball Valves for Extreme Conditions

In the industrial sector, valves are critical components of piping systems, and their performance and reliability directly affect the stability and safety of the entire production process. As a special type of valve, metal-seated ball valves are widely used in industries such as coal chemical processing and polysilicon production because of their ability to withstand high temperatures, strong corrosion, and complex media containing dust, solid particles, or slurry. However, it is precisely these harsh operating conditions that pose significant challenges to the long-term stable operation of metal-seated ball valves. This article provides an in-depth analysis of the problems encountered during their use and proposes corresponding optimization designs and solutions.

Differences Between Metal-Seated and Soft-Seated Ball Valves

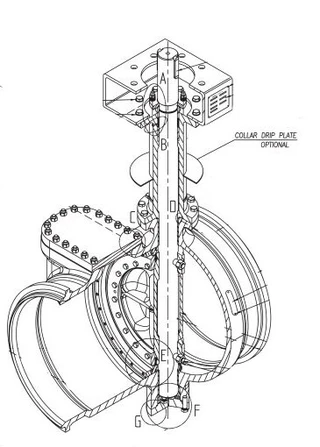

The most fundamental difference between metal-seated ball valves and soft-seated ball valves lies in the materials used for the sealing pair. In soft-seated ball valves, the ball is made of metal, while the seat is manufactured from non-metallic materials. Their sealing principle is relatively simple: the sealing force between the metal ball and the non-metallic seat causes the seat to deform, transforming the original line contact into surface contact. This deformation effectively compensates for surface irregularities on the ball. Even if the sealing force fluctuates, the impact on sealing performance is relatively minor.

In contrast, both the ball and the seat of a metal-seated ball valve are made of metal. Due to the high hardness of metallic materials, significant deformation under sealing force is difficult to achieve. As a result, metal-seated ball valves require a much higher sealing force to ensure tightness. Under this force, the seat sealing surface undergoes only slight deformation, closely conforming to the surface of the ball to achieve sealing. However, this sealing mechanism places extremely high demands on the control of sealing force. Even slight variations in sealing force can lead to sealing failure.

Challenges for Metal-Seated Ball Valves Under Harsh Conditions

Thanks to their all-metal sealing structure, metal-seated ball valves can operate under high-temperature, highly corrosive conditions and in media containing dust, solid particles, or slurry. Nevertheless, these harsh environments impose severe challenges on their long-term stable operation. Such challenges not only degrade sealing performance but can also result in frequent maintenance and replacement, increasing maintenance costs and downtime. Therefore, understanding the root causes of these challenges is essential for optimizing valve design and improving reliability.

1. Effects of High Temperature and Strongly Corrosive Media

Under high-temperature and strongly corrosive conditions, the sealing surface materials of metal-seated ball valves are subjected to extreme stress. Elevated temperatures reduce the mechanical properties of metallic materials while accelerating corrosion. For example, in the coal chemical industry, high-temperature and high-pressure synthesis gas contains significant amounts of corrosive components such as hydrogen sulfide and carbon dioxide. At elevated temperatures, these gases aggressively attack metal sealing surfaces, leading to spalling and damage that ultimately cause internal leakage.

2. Erosion and Wear Caused by Solid Particles

The presence of solid particles represents another major challenge. In polysilicon production, solid particles such as silicon powder are carried by the process medium and cause intense erosion at the flow passages of the ball and seat. These particles not only wear down the sealing surfaces but may also pass through the flow openings and enter the sealing interface, causing catastrophic damage. Statistics show that valve rework caused by solid particles accounts for more than 20% of total maintenance cases. Once scratches on the sealing surface exceed 0.1 mm, re-lapping is generally no longer feasible, and the ball and seat usually must be replaced.

3. Excessive Operating Torque

Due to their sealing mechanism, metal-seated ball valves inherently require 3–4 times more operating torque than soft-seated ball valves of the same size. In media with strong adhesion properties, such as slurry or dust-laden fluids, solid–liquid mixtures can adhere to the external sealing surfaces of the ball and seat, further increasing the torque required for opening and closing. In extreme cases, the valve may seize completely, rendering it inoperable. Such torque-related issues account for at least 40% of total valve failures. At present, there is no comprehensive solution to excessive torque, and most cases require disassembly and repair.

Optimization Design and Solutions for Metal-Seated Ball Valves

In the face of these severe challenges, merely identifying the problems is not sufficient. Effective countermeasures must be actively pursued. By optimizing sealing surface structures, material selection, and the application of springs and disc springs, metal-seated ball valves can be comprehensively improved to enhance performance and reliability under harsh conditions. The following sections examine these optimization strategies in detail.

1. Optimization of Sealing Surface Structure

To mitigate erosion and wear caused by solid particles, a double-scraper seat structure can be adopted. This design incorporates two stepped edges on both sides of the seat sealing surface, functioning like two scrapers. During valve operation, these steps effectively scrape off solid particles adhering to the ball, preventing them from entering the sealing interface. Although this structure increases manufacturing costs, it is highly effective in applications with a high concentration of solid particles. However, for clean media such as water or steam, the scraper structure may reduce seat strength and is therefore not recommended.

2. Application of Springs and Disc Springs

Springs in metal-seated ball valves are primarily used to regulate sealing force. Since the elastic force of a spring follows a linear or quadratic relationship with compression, its effective adjustment range is relatively limited and suitable only for fine tuning. When leakage occurs and the sealing force deviates significantly from the standard value, adjustment is typically achieved by modifying the thickness of the seat pressure ring installed behind the seat.

Disc springs, due to their unique structure and performance characteristics, are widely used in metal-seated ball valves. Their elastic properties allow them to maintain stable sealing force over a wide pressure range, effectively overcoming the limited adjustment range of conventional springs. However, disc springs also have drawbacks: process materials may enter the disc spring area, causing jamming and loss of elastic compensation. To address this issue, discharge grooves can be designed to allow trapped materials to be expelled, ensuring proper disc spring function.

3. Selection of Sealing Surface Coating Materials

The choice of sealing surface coating materials is critical to valve performance. Suitable coatings can significantly enhance wear resistance and corrosion resistance while preventing adhesion between sealing pairs. Extensive testing and research have shown that certain hard alloy coatings exhibit exceptional suitability for specific operating conditions, effectively addressing issues such as adhesion, oxidation, heat accumulation, and electrostatic discharge in high-pressure, high-temperature, and clean gas applications. In media containing solid particles, these hard alloy coatings also demonstrate markedly improved wear resistance and service life. Therefore, coating selection should be based on specific process media and operating requirements, combined with an appropriate sealing structure design to achieve optimal sealing performance.

4. Other Optimization Measures

In addition to the above strategies, several other measures can further improve valve performance and reliability. These include ensuring sharp seat edges to provide a scraping effect that prevents particle ingress; carefully controlling surface roughness and dimensional tolerances between the seat ring and valve body seat groove to prevent extrusion of graphite sealing materials and seat adhesion; ensuring that seat support components do not tilt during operation; and verifying that seat surfaces possess sufficient hardness and are free from stains, cracks, or dents. Attention to these details can significantly enhance overall valve performance and extend service life.

Maintenance of Metal-Seated Ball Valves

Even with optimized design, regular maintenance remains essential in actual operation. The following maintenance practices are recommended:

- Regular Inspection of Sealing Surfaces: Periodically inspect sealing surfaces to detect scratches or wear early. If scratches exceed 0.1 mm, the ball and seat should be replaced immediately to prevent further damage and leakage.

- Removal of Solid Particles: In applications with high solid content, regularly clean the valve interior to prevent particle accumulation and further damage to sealing surfaces. Cleaning can be performed using specialized equipment or manual methods.

- Inspection of Springs and Disc Springs: Regularly check the elastic performance and condition of springs and disc springs. If deformation, damage, or loss of elastic compensation is detected, components should be replaced promptly to ensure stable sealing force.

- Lubrication and Corrosion Protection: Periodically lubricate moving parts to reduce friction and wear. Apply corrosion protection to external surfaces to prevent damage caused by environmental exposure.

Conclusion

The application of metal-seated ball valves under high-temperature, highly corrosive conditions and in media containing solid particles presents numerous challenges. Through optimization of sealing surface structures, appropriate selection of sealing surface coating materials, application of springs and disc springs, and implementation of effective maintenance practices, valve performance and reliability can be significantly improved, and service life can be extended. Nevertheless, the optimization and advancement of metal-seated ball valve technology is an ongoing process. As industrial technologies continue to evolve, further research and development will be required to meet increasingly stringent industrial demands.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/optimizing-metal-seated-ball-valves-for-extreme-conditions.html