Comparing Safety Valves and Pressure Reducing Valves

In the industrial field, valves are indispensable components that play a critical role in various pipelines and equipment. Today, we take an in-depth look at two very important types of special-purpose valves: safety valves and pressure reducing valves. Although both belong to the valve family, they differ significantly in function and application. Each plays a unique and vital role in industrial systems, ensuring safety and stable operation.

Safety Valves: Guardians of System Safety

In industrial production, safety is always one of the most important considerations. During operation, equipment and pipeline systems face various potential risks, among which loss of pressure control is a common issue. To effectively address this challenge, safety valves were developed. They act like guardians within industrial systems, constantly protecting system safety.

1. Basics of Safety Valves

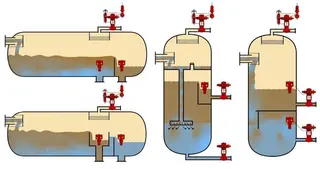

A safety valve is an automatic valve primarily used to prevent boilers, pressure vessels, and pipelines from damage caused by overpressure. Imagine a boiler or pressure vessel as a sealed “pressure cooker.” When internal pressure continues to rise beyond what the equipment can withstand, dangerous situations such as explosions may occur. A safety valve functions as a “safety guard.” When the pressure slightly exceeds the normal operating pressure, the valve automatically opens—much like opening a pressure relief outlet—allowing part of the fluid (gas or liquid) to be discharged and thereby reducing the pressure. When the pressure drops slightly below the normal operating pressure, the safety valve automatically closes, stops the discharge, and maintains a tight seal, ensuring that the system operates within a safe pressure range.

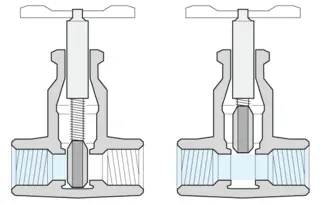

2. Working Principle of Safety Valves

The operating principle of a safety valve is based on automatic pressure control. Under normal operating conditions, the valve closure element (such as the disc) remains in a normally closed position, held tightly shut by an external force (such as spring force). When the medium pressure inside the equipment or pipeline rises above the specified value, the pressure of the medium overcomes the external force, pushing the closure element upward and opening the valve to discharge the medium. As the medium is released, the pressure gradually decreases. When the pressure drops slightly below the normal operating pressure, the external force once again becomes dominant, causing the closure element to close and the valve to stop discharging fluid. This entire process is automatic and requires no manual intervention, effectively protecting the system from the threat of overpressure.

3. Importance of Safety Valves

Safety valves are vital to the safety of industrial systems. They are pressure relief safety devices that operate only when the working pressure exceeds the allowable limit. In equipment such as boilers, pressure vessels, and pipelines, safety valves serve as the last line of defense, preventing serious accidents such as explosions caused by overpressure. These devices typically operate under high pressure, and once pressure control is lost, the consequences can be catastrophic. The presence of a safety valve not only protects the equipment itself but, more importantly, ensures the safety of operating personnel and the entire industrial environment. Therefore, safety valves must undergo rigorous pressure testing before being put into service to ensure reliable performance at critical moments.

Pressure Reducing Valves: Experts in Precise Pressure Control

In the complex operation of industrial systems, in addition to safety valves that protect the system under abnormal pressure conditions, there is another type of valve that plays an indispensable role in daily operation, the pressure reducing valve. If safety valves are the last line of defense for system safety, then pressure reducing valves are the experts that ensure normal operation and precise pressure control. By accurately regulating pressure, they reduce high-pressure fluids to levels suitable for downstream equipment or processes, providing strong support for stable system operation.

1. Basics of Pressure Reducing Valves

A pressure reducing valve is a device that reduces a high-pressure medium to a lower-pressure medium. In many industrial systems, the inlet fluid pressure may be too high, exceeding the pressure range required by downstream equipment or processes. The function of a pressure reducing valve is to regulate and reduce the inlet pressure to a required outlet pressure and, by utilizing the energy of the medium itself, automatically maintain a stable outlet pressure. For example, in water supply systems, municipal water pressure may be relatively high, while internal building piping systems and water-using equipment may require much lower pressure. In such cases, a pressure reducing valve reduces the high-pressure water to meet downstream pressure requirements.

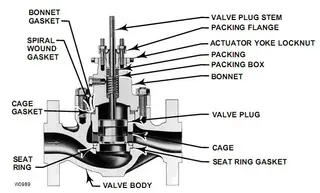

2. Working Principle of Pressure Reducing Valves

From a fluid mechanics perspective, a pressure reducing valve is a throttling element with variable local resistance. By changing the throttling area, it alters flow velocity and fluid kinetic energy, thereby creating different pressure losses to achieve pressure reduction. Specifically, inside the pressure reducing valve are adjustable components such as a valve disc or diaphragm. When the inlet pressure changes, the position of the valve disc adjusts accordingly. Through the regulation of the control system, the downstream pressure fluctuation is balanced against the spring force, keeping the downstream pressure constant within a certain error range.

For example, in pressure reducing valves based on a fixed-ratio reduction principle, the pressure reduction ratio between the inlet and outlet is controlled by the hydraulic ratio of a floating piston inside the valve body, and this reduction ratio is inversely proportional to the ratio of the piston areas on the inlet and outlet sides. Such valves operate smoothly without vibration, offer good sealing performance, reduce both dynamic and static pressure, and do not affect water flow rate while reducing pressure. They are therefore highly suitable for applications requiring precise pressure control.

3. Applications of Pressure Reducing Valves

Pressure reducing valves are widely used in various applications where pressure regulation is required. In water supply systems, they prevent excessive pressure from damaging pipelines and water-using equipment. In industrial pipeline systems, they control pressure between different process stages to ensure stable production. Unlike safety valves, pressure reducing valves operate continuously. They do not act only when pressure exceeds a certain value; instead, they continuously regulate inlet pressure to maintain outlet pressure within a preset range. This continuous pressure regulation capability makes pressure reducing valves essential in industrial production, as they meet the precise pressure requirements of different equipment and processes while improving overall system efficiency and reliability.

Differences Between Safety Valves & Pressure Reducing Valves

After understanding the functions and importance of safety valves and pressure reducing valves, it is necessary to examine their differences. Although both are indispensable valve types in industrial systems, they differ significantly in design purpose, operating mode, and application scenarios. Only by clearly understanding these differences can we correctly select and use them in practice to ensure safe and efficient industrial operation.

1. Functional Positioning

The functional positioning of safety valves and pressure reducing valves is fundamentally different. A safety valve is a protective safety valve whose primary task is to prevent system pressure from exceeding a set limit and to protect the system. When system pressure rises abnormally, the safety valve automatically opens to release pressure and prevent damage caused by overpressure. A pressure reducing valve, on the other hand, is a process valve designed to reduce system pressure from a higher level to a suitable required level. Its outlet pressure falls within a certain range, as long as the pressure within that range meets downstream system requirements. Pressure reducing valves maintain pipeline pressure within a safe range by adjusting the valve opening and are mainly used to regulate fluid pressure in the system, protecting equipment from excessive pressure and thereby extending equipment service life.

2. Operating Mode

In terms of operating mode, a safety valve typically opens automatically when pressure exceeds the set value, operating intermittently. It intervenes only under abnormal pressure conditions and provides emergency protection. A pressure reducing valve, by contrast, continuously controls pressure by adjusting the valve disc position. It is always in operation, constantly regulating inlet pressure to keep outlet pressure within a specified range. Its operation is continuous, requiring constant monitoring and adjustment to meet ongoing system pressure demands.

3. Application Scenarios

Safety valves are commonly used in boilers, pressure vessels, and similar equipment that operate under relatively high pressure, where loss of pressure control can have extremely serious consequences. The purpose of a safety valve is to prevent such equipment from being damaged by overpressure and to ensure the safety of equipment and personnel. Pressure reducing valves are used in water supply systems, industrial pipelines, and other applications where pressure regulation is required. In these scenarios, precise pressure control is essential, and pressure reducing valves effectively reduce high-pressure fluids to meet the pressure requirements of downstream equipment or processes.

Choice Between Safety Valves and Pressure Reducing Valves

Because safety valves and pressure reducing valves differ in function and design purpose, they generally cannot replace one another. In practical industrial systems, correct selection and use of these valves are crucial to ensuring safety and efficiency. Incorrectly using a pressure reducing valve in an application requiring overpressure protection may lead to equipment damage due to overpressure. Conversely, using a safety valve in an application requiring continuous pressure regulation cannot meet the system's demand for precise pressure control.

In some specific cases, where both overpressure protection and pressure regulation are required, both types of valves may need to be used together. For example, in a complex industrial pipeline system, a pressure reducing valve can be used to reduce high-pressure fluid to a suitable range, while a safety valve serves as the final line of defense to prevent overpressure caused by unexpected conditions.

When selecting safety valves and pressure reducing valves, multiple factors must be considered. For safety valves, appropriate models should be selected based on equipment operating pressure, medium type, temperature, and other parameters, and the valves must pass rigorous pressure testing and comply with relevant safety standards. For pressure reducing valves, selection should be based on required outlet pressure range, flow capacity, and medium characteristics. In addition, installation and operation must strictly follow procedures, and regular maintenance and inspection should be carried out to ensure reliable operation.

Conclusion

Both safety valves and pressure reducing valves play indispensable roles in industrial systems. Safety valves are the guardians of system safety, automatically opening to release pressure when abnormal pressure rises and preventing equipment damage due to overpressure. Pressure reducing valves are experts in precise pressure control, maintaining pipeline pressure within a safe range by regulating valve opening and meeting the system's precise pressure requirements. Although their functions and applications differ, both are essential to ensuring the safety and stable operation of industrial systems.

Correct selection and use of safety valves and pressure reducing valves can effectively improve system operating efficiency, extend equipment service life, and provide safety protection for operators and the entire production environment. In industrial production, a thorough understanding of the characteristics and applications of these two types of valves, and their proper use in appropriate scenarios, is key to ensuring safe, efficient, and stable system operation.

Send your message to this supplier

Related Articles from the Supplier

Comparing Safety Valves and Pressure Reducing Valves

- Dec 18, 2025

Related Articles from China Manufacturers

Comparing Soft Seal and Metal Seat Gate Valves

- Feb 25, 2024

Comparing Rising and Non-Rising Stem Gate Valves

- Mar 01, 2024

Comparing Pneumatic and Electric Control Valves

- Apr 26, 2024

Comparing Flat Welding Flanges and Weld Neck Flanges

- Feb 29, 2024

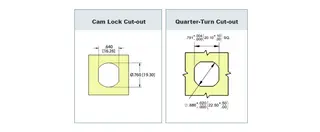

Comparing Cam Locks and Quarter Turn Latches

- Apr 07, 2024

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/comparing-safety-valves-and-pressure-reducing-valves.html