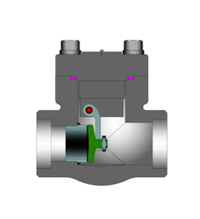

API 594 Wafer Check Valves, ASTM A351 CF8M, 4 IN, CL300, Lug

Product Name: API 594 Wafer Check Valves

Type: Wafer Check Valve

Design Standard: API 594

Body Material: ASTM A351 CF8M

Size: 4 Inch, DN100

Pressure: Class 300 LB, PN50

End Connection: Lug

Temperature Range: -29°C to 595°C

Medium: Water, Gas, Oil, etc.

We specialize in manufacturing wafer check valves with a distinctive center vertical pin shaft design. When the valve opens, the fluid's resultant force is concentrated on the disc's sealing face center, while the counter spring support force is applied to the disc surface center. This innovative design allows the disc to open from its root first, thereby avoiding the sealing surface wear typically seen in traditional valves and significantly improving the valve seal's durability. The wafer check valve functions automatically, opening and closing in response to the medium's flow, and is specifically engineered to prevent the medium's reverse flow.

Technical Specification

» Product: Dual Plate Check Valve

» Nominal Diameter: NPS 2-60 Inch (DN50-DN1500)

» Design Pressure: Class 150-2500 LB (PN10-PN420)

» Materials: ASTM A216 WCB, WCC, A217 WC6, WC9, C5, C12A, A352 LCB, LCC, A351 CF8, CF8M, CF3M, CF8C

» End Connections: Wafer, Lug, Clamp, Flanged

» Medium: Water, gas, oil, etc.

» Temperature Range: -29°C to 595°C

Standards and Compliance

» Design and Manufacture: API 594, API 6D, JB/T 8937

» Face to Face (End to End): API 594, API 6D, JB/T 8937, DIN 3202

» Flanged Connection: ANSI B16.5, DIN 2543-2548, JB/T 9112-24

» Butt Welded End: ANSI B16.25

» Test and Inspection: API 598, DIN 3230, JB/T 9092

Product Features

» Light and Compact: The wafer check valve is engineered to be lightweight and compact, facilitating easy installation and handling while conserving valuable space in diverse applications.

» Zero Leakage Sealing Design with Soft Seated: This valve boasts a zero leakage sealing design with a soft seat, guaranteeing a flawless seal and eliminating fluid leakage.

» Non-Slam Design: The valve is equipped with a non-slam design to prevent abrupt closure, thereby minimizing noise and potential damage to both the valve and connected piping.

» Bubble Tight Closure: Achieving a bubble-tight closure, the valve offers superior sealing reliability and effectively prevents backflow of the medium.

» Discs Open 85°: The discs open to an 85° angle, ensuring minimal pressure drop across the valve. This design optimizes flow efficiency and reduces energy consumption.

Send your message to this supplier

Related Articles from the Supplier

Classification Of Check Valves

- Dec 14, 2024

How to Choose the Appropriate Check Valves?

- Oct 21, 2025

Related Articles from China Manufacturers

Valves in Stock for Fast-track Order

- Nov 01, 2023

Wafer Jacked Ball Valves in SS 304

- Feb 10, 2021

Improvement in Butterfly Check Valves

- Jun 29, 2022

The Differences Between Ball Valves and Globe Valves

- May 10, 2019

Improvement in Butterfly Check Valves

- Jul 13, 2022

Stainless Steel Gate Valve, ASTM A351 CF8M

- Dec 03, 2020

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Address: Dongou Industrial Zone, Oubei, Wenzhou, Zhejiang, China

- Phone: 86 577 5798 7171

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/api-594-wafer-check-valves-astm-a351-cf8m-4-in-cl300-lug.html

-320x320.webp)