The Introduction of Y-Type Globe Valve

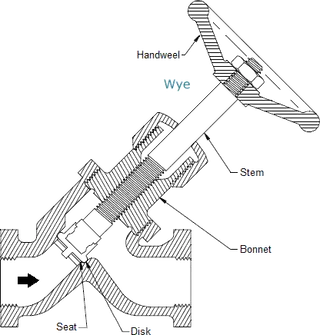

Valves are essential to pipeline systems, and the Y-type globe valve, also called a straight-flow globe valve, is used extensively in many industrial and engineering applications. The Y-type globe valve, which is distinguished by its special design in which the stem and channel form a specific angle, as well as the sealing surface of the valve seat and the intake and outlet passageways, offers a variety of unique functions and advantages.

Construction of Y-Type Globe valve

The Y-Type Globe valves typically have rising stems, and the bigger models feature an external screw-and-yoke design. The Globe valve's parts resemble those of the gate valve. The seats in this kind of valve are positioned either parallel to or at an angle to the flow line.

Y-Type Globe valve maintenance is comparatively simple because the seats and discs may be easily replaced or refurbished. Because of this, Y-Type Globe valves are especially well suited for services that call for regular valve maintenance. The reduced disc travel helps save operator time when valves are manually handled, particularly when the valves are often adjusted.

The types of discs used are the primary source of diversity in Y-Type Globe-valve design. Plug-type discs have a broad bearing surface and a long, tapered shape. Maximum resistance to the fluid stream's erosive effect is provided by this kind of seat. The flat face of the composition disk is forced up against the seat aperture in the shape of a cap. High differential pressure throttling is less appropriate for this kind of seat layout.

In iron Bronze is typically used for seat rings, globe valves, and discs. Steel-Globe valves with temperatures up to 750°F (399°C) typically have stainless steel trim, which offers resistance to galling and seizing. Differential hardness values are typically obtained by heat-treating the mating faces. Cobalt-based alloys and other trim materials are also utilized.

In order to guarantee full-bearing surface contact when the valve is closed, the seating surface is ground. A lengthy disc locknut maintains alignment for lower pressure classes. Disc guides are cast into the valve body to accommodate higher pressures. To keep the disc face and seat ring from galling, the disc rotates freely on the stem. Galling of the stem and disc at the point of contact is prevented by the stem bearing against a hardened thrust plate.

Working Principle

Because the Y-type globe valve falls between the straight-flow and angled-flow valves, its operation is quite simple. The flow passage becomes more aligned with the axis when the valve body and seat orifice are designed at a particular angle, which lowers pressure loss as fluid flows through the valve. This innovative concept is widely used in various applications, especially steam systems. Furthermore, the Y-type globe valve can only be used in certain fluid control situations because it only allows one flow direction.

1. Valve Opening

The valve disc is lifted away from the seat by the stem's upward movement when the handwheel or actuator is turned. The fluid route opens as the valve disc progressively rises, enabling smooth fluid flow. The fluid flowing through the valve has less resistance because of the Y-type structure design, which produces a smoother flow.2. Valve Closing

The stem descends when the handwheel or actuator rotates in the opposite direction, bringing the valve disc closer to the seat. The valve disc entirely blocks the fluid route and stops the flow when it makes tight contact with the seat, creating a seal. Excellent sealing performance is ensured by the design of the sealing surfaces between the valve disc and seat, which stops fluid leakage.

Major Advantages

Y-type globe valves, sometimes referred to as straight-flow globe valves, are a popular option in many industrial and technical applications due to their many benefits.

Simple Structure: Because of its relatively uncomplicated construction, the Y-type globe valve is easy to manufacture and maintain.

Short Opening and Closing Time: The valve has short opening and shutting periods because of its narrow working stroke, which makes it useful in circumstances demanding quick fluid control.

Excellent Sealing: The valve's lifespan is increased, friction is decreased, and sealing effectiveness is improved by using hard alloy overlay on the valve seat and valve disc sealing surfaces.

Suitability for Specific Media: especially useful for managing pipelines with coking and solid particles as well as pipes used in alumina oxidation procedures.

Several Disadvantages

Y-type globe valves have many benefits, but there are some drawbacks that should be considered.

High Fluid Resistance: Because of the substantial fluid resistance caused by its design, the Y-type globe valve requires a lot of force to open and close.

Limited Applicability: Particle-containing, highly viscous, or coking-prone media should not be used since they can damage or impede valve performance.

Poor Regulation Performance: Because of its comparatively poor regulation capabilities, the Y-type globe valve is not appropriate for applications that call for frequent flow rate modifications.

In conclusion, despite some drawbacks, the Y-type globe valve has a lot to offer and can be used in fluid control systems. To assure the best option for accomplishing efficient fluid control and pipeline management, it is crucial to take certain engineering requirements and fluid properties into account when choosing a valve type.

Send your message to this supplier

Related Articles from the Supplier

The Introduction of Y-Type Globe Valve

- Dec 13, 2025

The Advantages of Metal -to- Metal Butterfly Valve

- Aug 17, 2018

The Difference Between Gate Valve and Globe Valve

- Aug 23, 2018

The Eight Common Faults and Treatments of valve

- Dec 05, 2018

How to install valves in the right way

- Dec 13, 2018

Related Articles from China Manufacturers

The Introduction of Lock Material

- Dec 09, 2015

The Introduction and Application of Cut Wire Shot

- Jul 27, 2016

The Introduction of Cold Rolled Seamless Pipes

- Sep 21, 2017

The Introduction of Forged Tie Rod Ends

- Mar 25, 2024

The Introduction of Chinese Standards of Door Locks

- May 14, 2021

The Introduction of Aluminum Silicate Fiber

- Feb 29, 2016

Related Products Mentioned in the Article

Shanghai Jonloo Machine MFG Co., Ltd.

- www.jonloovalves.com

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.jonloovalves.com/news/the-introduction-of-y-type-globe-valve.html