Forging Equipment Explained: Types, Principles, and Uses

Forging is one of the core processes in metalworking. By applying pressure to metal billets, plastic deformation is induced to obtain parts with the desired shape and mechanical properties. In forging production, equipment selection directly determines product quality, production efficiency, and manufacturing cost. Based on different driving principles and process characteristics, modern forging equipment can generally be divided into six major categories: forging hammers, hot die forging presses, screw presses, upset forging machines, hydraulic presses, and rotary forming equipment. Each type features unique working principles and application ranges. Understanding these characteristics helps enterprises make informed decisions in practical production, optimize process flows, and improve economic performance.

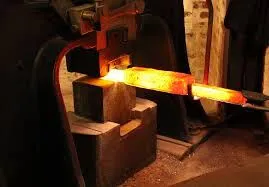

Forging Hammer Equipment

After understanding the overall classification and application scenarios of forging equipment, it is necessary to begin with the most fundamental and historically established type. Forging hammers remain among the most widely used forging machines today. With advantages such as simple structure, strong adaptability, and low investment cost, they hold an irreplaceable position in small and medium-sized forging enterprises. The following sections provide a detailed introduction to their working principles, main types, and process characteristics.

1. Forging Hammer Working Principle

Forging hammers are among the most traditional and commonly used forging devices. Their operating principle is based on the fundamental law of converting kinetic energy into pressure. During the working stroke, the hammerhead, hammer rod, and piston accumulate kinetic energy and strike the billet placed on the anvil at high speed. The enormous energy released instantaneously completes the plastic deformation of the metal.

Forging hammers are classified as constant-energy machines. Their output energy mainly comes from two sources: the thrust generated by gas expansion within the cylinder and the gravitational potential energy of the hammerhead itself. When the hammerhead falls from a height, these energies combine and convert into impact force at the moment of contact with the workpiece.

2. Main Types of Forging Hammer Equipment

Modern forging hammer equipment includes several types:

- Air hammers: Driven by compressed air, featuring simple structures and convenient operation.

- Steam-air hammers: Powered by steam or compressed air, suitable for producing large forgings.

- High-speed hammers: Characterized by extremely high hammer velocities, ideal for precision die forging.

- Hydraulic die forging hammers: Integrate hydraulic technology for more precise energy control.

3. Forging Hammer Equipment Process Characteristics

Forging hammers exhibit highly distinctive operating characteristics. First, the effective impact energy of the hammerhead directly reflects the machine's forging capacity. Second, the relationship between load and stroke is nonlinear: the closer to the end of the stroke, the greater the impact energy. This makes forging hammers particularly suitable for processes requiring large deformation.

During forming, energy is released within milliseconds, and the hammerhead speed drops from its maximum to zero almost instantly. This “impact forming” feature fundamentally distinguishes forging hammers from other equipment. Additionally, the hammerhead has no fixed bottom dead center; forging accuracy relies primarily on the dies, placing higher demands on die design and manufacturing.

Hot Die Forging Press

- Mechanical Structure and Transmission: Hot die forging presses operate according to the crank-slider mechanism and are typical mechanically driven machines. The motor converts rotational motion into the reciprocating linear motion of the ram through a flywheel, clutch, and transmission system. This mechanical drive fundamentally differentiates their working characteristics from forging hammers.

- Core Process Characteristics: One of the most notable features of hot die forging presses is the presence of a fixed bottom dead center for the ram. This ensures a consistent endpoint for each stroke, helping maintain dimensional uniformity in forgings. The ram's speed and effective load vary with position: as it approaches the bottom dead center, speed decreases while load increases. In actual forging, forming can only be completed when the required process load is lower than the press's effective capacity. If the ram load exceeds machine capability, drilling and overload may occur, making reliable protective devices essential. Forging accuracy is closely related to the manufacturing precision of the transmission mechanism and the rigidity of the frame. Insufficient rigidity can lead to elastic deformation and negatively affect product quality.

Screw Press

- Transmission Mechanism: The screw press uses a screw–nut transmission system to convert the bidirectional rotational motion of the flywheel into the vertical linear movement of the ram. This design positions it performance-wise between die forging hammers and hot die forging presses, combining some advantages of both.

- Operating Characteristics: The ram stroke of a screw press is not fixed, allowing reversal before reaching the lowest position. Operators can flexibly control impact energy and the number of blows according to the required deformation. During die forging, the deformation resistance of the workpiece is balanced by the elastic deformation of the closed frame, similar to a hot die forging press. This equipment is highly adaptable, suitable for both precision die forging and small-batch, multi-variety production. The adjustable energy feature enables good economic performance when forging different materials and component sizes.

Upset Forging Machine (Horizontal Forging Machine)

- Structural Features: Upset forging machines, also known as horizontal forging machines, still belong to the crank press category in terms of motion principles, but their working components move horizontally rather than vertically. The machine drives two sliders through a motor and crank-link mechanism: one holds the punch for forging, while the other carries the die for bar centering.

- Process Advantages: These machines primarily produce die forgings using the localized upsetting method. In addition to upsetting, they can perform punching, bending, flanging, and cutting operations. Key advantages include high rigidity, fixed stroke, and strong dimensional stability along the forging direction. Since forming relies on static pressure, vibration is minimal, and massive foundations are unnecessary. Owing to these characteristics, upset forging machines are widely used in batch production for the automotive, tractor, bearing, and aerospace industries, making them highly versatile forging equipment.

Hydraulic Press

Unlike mechanically driven hot die forging presses and screw presses, hydraulic presses employ a completely different method of energy transmission. If mechanical presses rely on “rigid” mechanical motion, hydraulic presses utilize the “flexibility” of liquid pressure. This fundamental difference gives hydraulic presses unique technological advantages in large forging production and precision forming.

1. Hydraulic Transmission Principle

Hydraulic presses use a hydraulic drive system in which the pump station converts electrical energy into hydraulic pressure energy. The forging process is completed through hydraulic cylinders and a ram (moving beam). These machines are classified as “constant-load equipment,” with output load primarily determined by the working pressure of the fluid and the effective area of the hydraulic cylinder.

2. Unique Process Advantages

- Constant load throughout the stroke: Maximum pressing load can be achieved at any position during the working stroke, making the press ideal for extrusion processes where the load remains nearly constant over long strokes.

- Simple overload protection: A relief valve in the hydraulic system automatically releases fluid when the load exceeds the preset value, effectively protecting both equipment and dies.

- Flexible parameter adjustment: By regulating pressure and flow, different load, stroke, and speed characteristics can be obtained, expanding the application range and enabling process optimization.

- Accuracy compensation capability: Since there is no fixed bottom dead center, hydraulic pressure control can partially compensate for the influence of machine rigidity on dimensional accuracy.

In recent years, advances in hydraulic technology have significantly improved forging quality and precision, leading to increasingly widespread use of hydraulic presses in large forgings and precision forming applications.

Rotary Forming Forging Equipment

- Working Principle: Rotary forming equipment uses motor drives and mechanical transmission to create relative rotational motion between the working components and the workpiece during processing. Depending on the motion mode, either the working components rotate, the workpiece rotates, or both rotate simultaneously.

- Main Types and Applications: This category includes cross-wedge rolling mills, roll forging machines, ring rolling mills, rotary swaging machines, orbital rolling machines, and radial forging machines. Their common characteristic is that the billet undergoes localized stress and continuous local deformation. As a result, the required deformation force and energy are relatively small, yet large-sized forgings can still be produced. Due to their rotational nature, these machines are particularly suitable for machining axisymmetric forgings such as shafts, discs, and rings, and are widely used in the mass production of bearings, gears, flanges, and similar components.

Equipment Selection Recommendations

When selecting forging equipment, the following factors should be considered comprehensively:

- Production volume: Dedicated equipment such as upset forging machines and ring rolling mills is suitable for large-scale production, while versatile machines like hydraulic presses and screw presses are better for small-batch, multi-variety manufacturing.

- Forging characteristics: Rotary forming equipment is preferred for axisymmetric parts, while forging hammers or hydraulic presses are better suited for complex shapes.

- Precision requirements: High-precision components should be produced using hot die forging presses or precision hydraulic presses.

- Energy consumption and environmental impact: Hydraulic presses generate less vibration and noise, while rotary forming equipment generally consumes less energy.

- Investment cost: Mechanical presses typically require higher initial investment but have lower maintenance costs, whereas hydraulic presses involve relatively moderate investment.

Conclusion

Forging equipment comes in many forms, each with its own application scope and process advantages. From traditional forging hammers to modern CNC hydraulic presses, and from simple drop hammers to precision ring rolling mills, technological advancements in equipment have driven the development of the entire forging industry.

When selecting machinery, enterprises should fully understand the working principles and process characteristics of each type, align them with product requirements and production conditions, and make optimal decisions. With the rapid advancement of intelligent manufacturing, forging equipment is evolving toward automation, digitalization, and sustainability, providing stronger support for the high-quality development of modern manufacturing.

Send your message to this supplier

Related Articles from the Supplier

Forging Methods, Advantages and Applications

- May 11, 2015

Classifications of Forging

- Mar 10, 2016

Hot Forging vs. Cold Forging

- May 02, 2024

Evolution of Forging Techniques throughout History

- May 11, 2024

Key Considerations in Hot Forging

- May 25, 2024

The Impact of Material Defects in Forging Parts

- May 30, 2024

Related Articles from China Manufacturers

Aluminum Forging Process and Equipment Requirements

- Nov 20, 2024

Forging Methods, Equipment, and Applications

- Jul 26, 2024

Differences between Forging and Casting Valves

- Sep 23, 2016

Forging Medium and High-pressure Valves

- Jun 03, 2024

Analysis on the Development of Forging Industry

- Jul 10, 2020

Matters Needing Attention in Forging Process

- Aug 19, 2020

Risky Factors and Main Reasons of Forging Production

- Aug 27, 2020

The Characteristics of Forging Workshop—Part Two

- Sep 17, 2020

Related Products Mentioned in the Article

Supplier Website

Source: https://www.forging-casting-stamping.com/forging-equipment-explained-types-principles-and-uses.html